Film forming device with detachable gas inlet and outlet structure

A film-forming device and detachable technology, which is applied in the field of film-forming devices with a detachable air inlet and outlet structure, can solve the problems that the transparent conductive film coating process cannot be implemented, and achieve the effects of easy cleaning, convenient disassembly, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

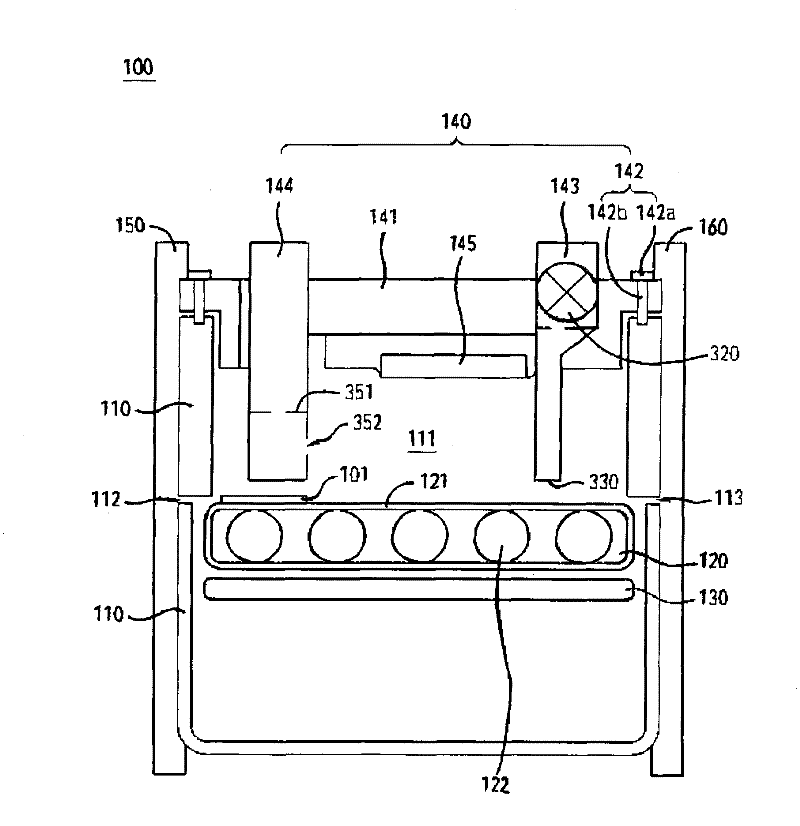

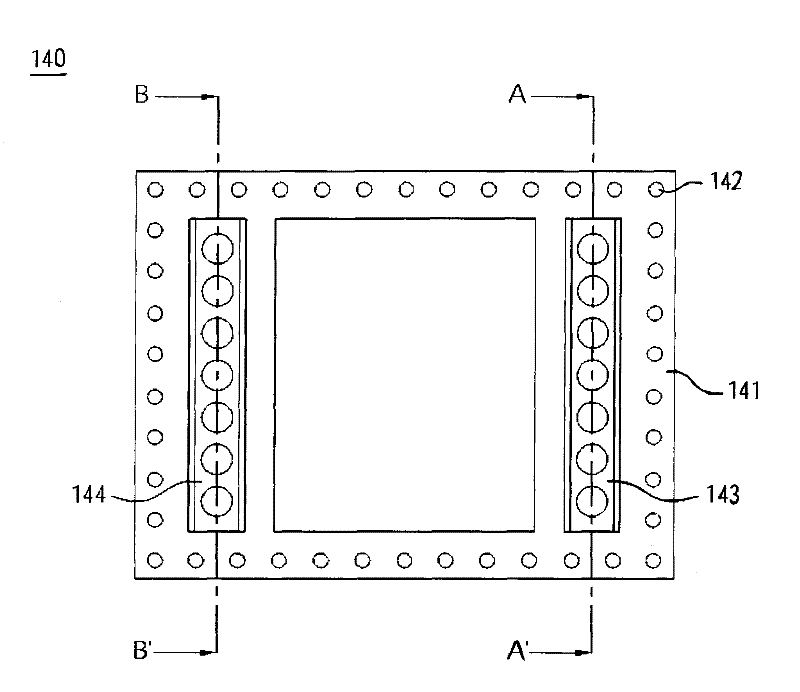

[0051] Please refer to figure 1 , is a schematic diagram of the first embodiment of the present invention, disclosing a film forming device 100 with a detachable gas inlet and outlet structure. The film forming device 100 includes a furnace body 110 , a conveying device 120 , a heater 130 , a detachable gas inlet and outlet structure 140 , a connecting element 150 and a connecting element 160 .

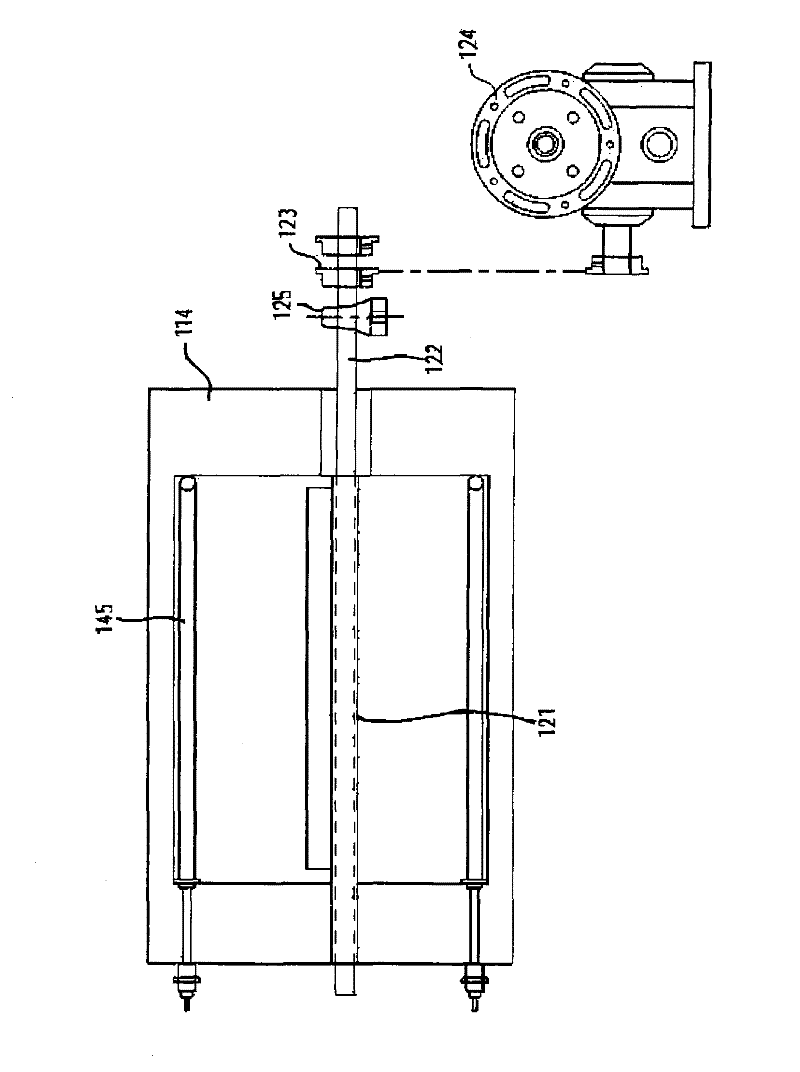

[0052] The film forming operation is performed in the film forming chamber 111 inside the furnace body 110 . The film forming chamber 111 has a substrate input port 112 and a substrate output port 113 , so that the substrate 101 to be film-formed is input through the substrate input port 112 and output through the substrate output port 113 . The furnace body 110 is equipped with heat insulating material to prevent the heat loss of the furnace body 110 . Insulation materials can be such as figure 2 The thermal insulation cotton 114 shown. For the substrate 101, glass, stainless st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com