Method for detecting micro-arc oxidation arcing characteristics of alloy by using anodic polarization curve

A technology of anodic polarization and micro-arc oxidation, applied in electrolysis process, electroforming, etc., can solve the problems of large workload, waste of electric energy and solution raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0015] Specific implementation mode 1: The method for detecting the arcing characteristics of alloy micro-arc oxidation by using the anodic polarization curve in this embodiment is carried out according to the following steps:

[0016] 1. Prepare the electrolyte to be verified;

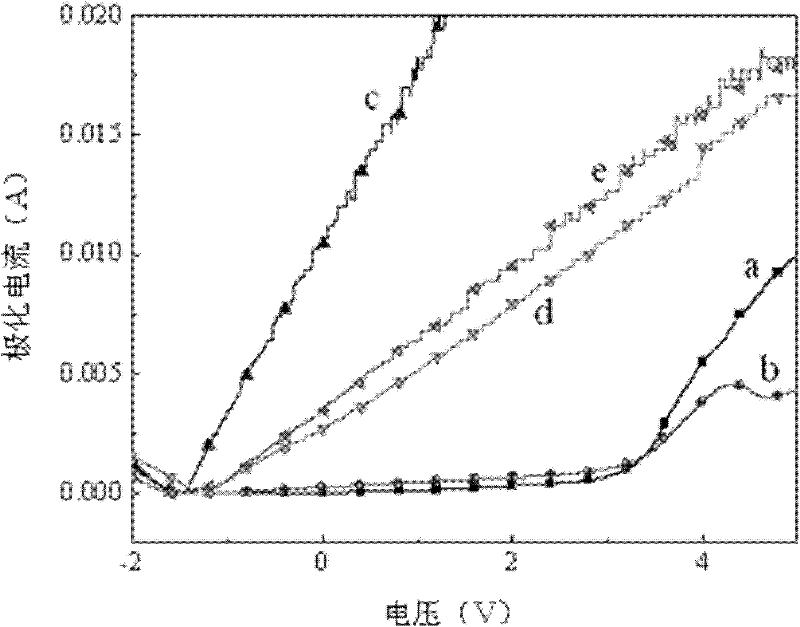

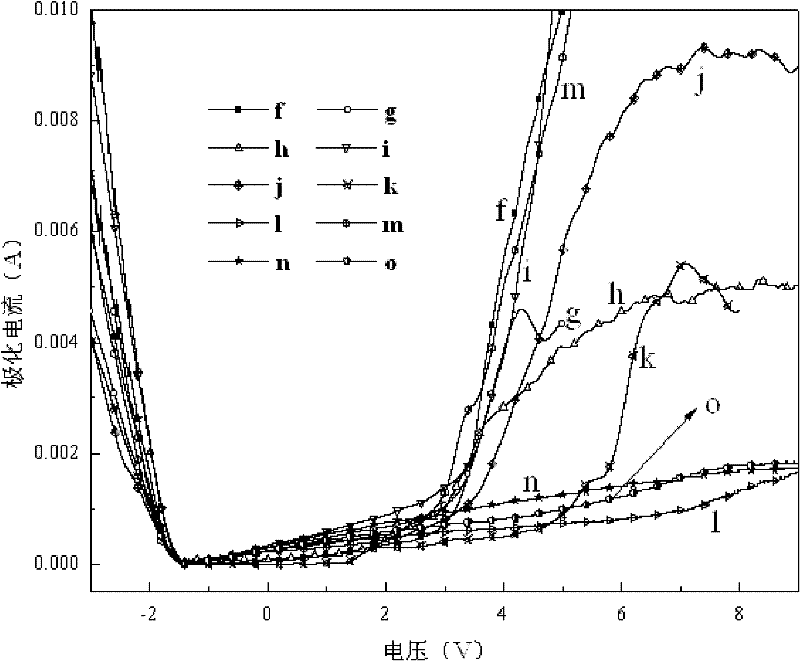

[0017] Two, measure the anodic polarization curve with the voltage U as the abscissa and the current I as the ordinate in the electrolytic solution to be verified obtained in step 1;

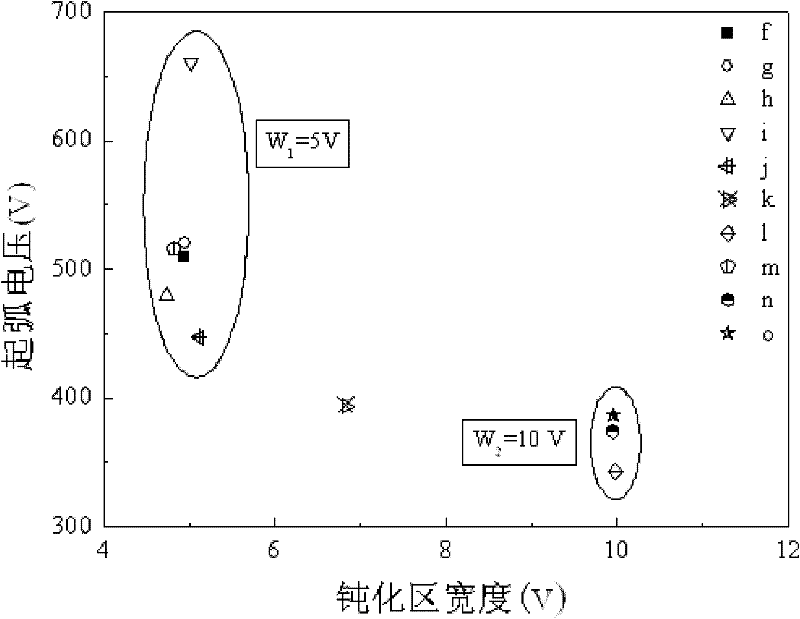

[0018] 3. On the anodic polarization curve measured in step 2, if there is no passivation zone, the alloy cannot undergo micro-arc oxidation in the electrolyte; if there is a passivation zone, the alloy can undergo micro-arc oxidation in the electrolyte Arc oxidation; the wider the passivation interval, the lower the voltage of the alloy in the electrolyte for micro-arc oxidation arc discharge; when the passivation interval is similar, the polarization current on the anodic polarization curve before the passivation film...

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment differs from Embodiment 1 in that the alloy in step 2 is magnesium alloy, aluminum alloy or titanium alloy. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the anodic polarization curve in step 2 is measured by a potentiostatic method. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com