Construction method for energy aggregate wall with fireproof, heat-insulating and sound-insulating effects

A technology of energy and pellets, applied in the direction of sound insulation, fire protection, building components, etc., can solve the problems of being unable to block cold and temperature, difficult to retain warm indoor air, and affecting the quality of life between adjacent floors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

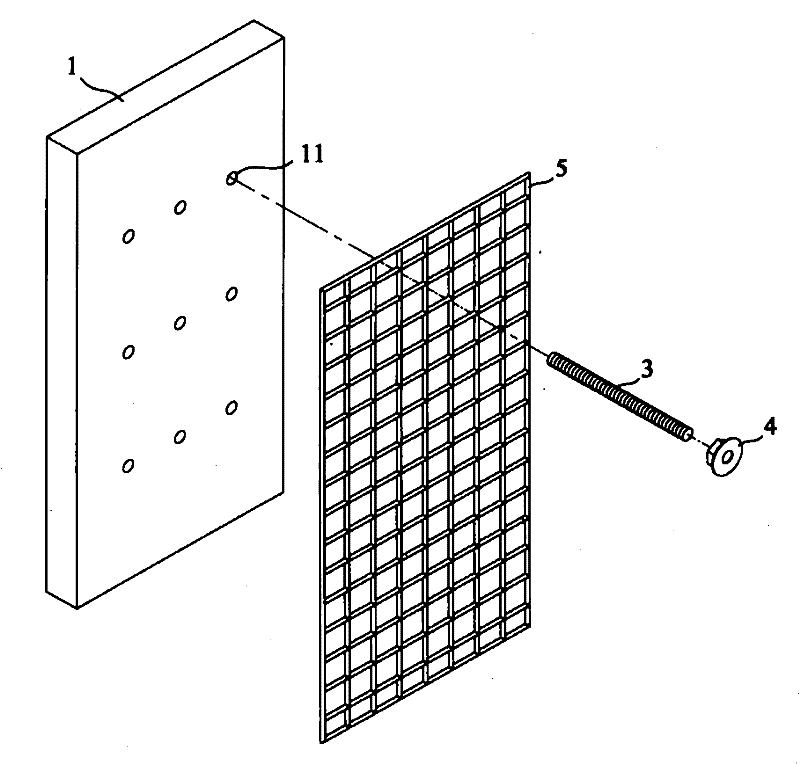

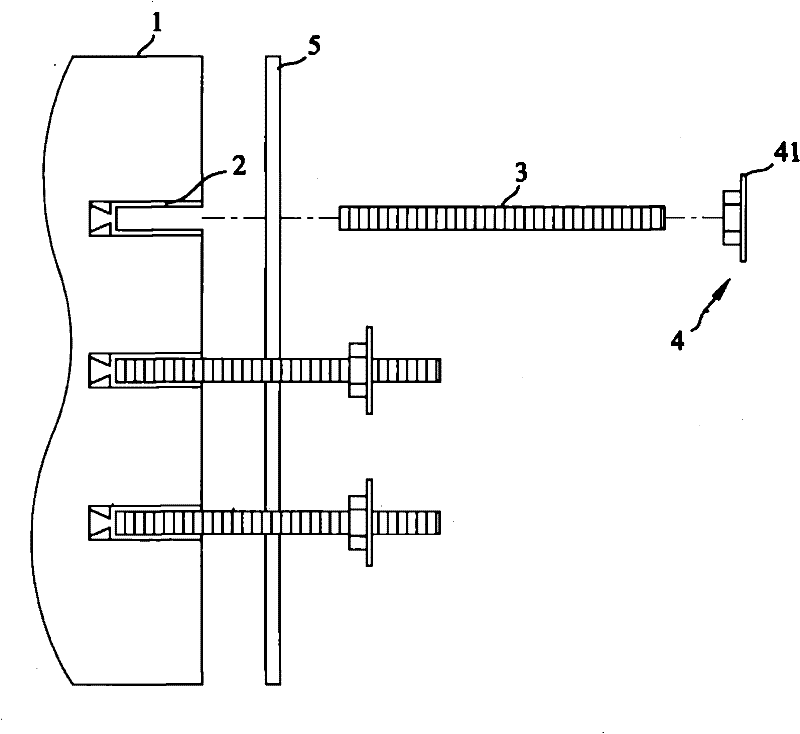

[0013] The implementation of the present invention will be described in more detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it after studying this specification.

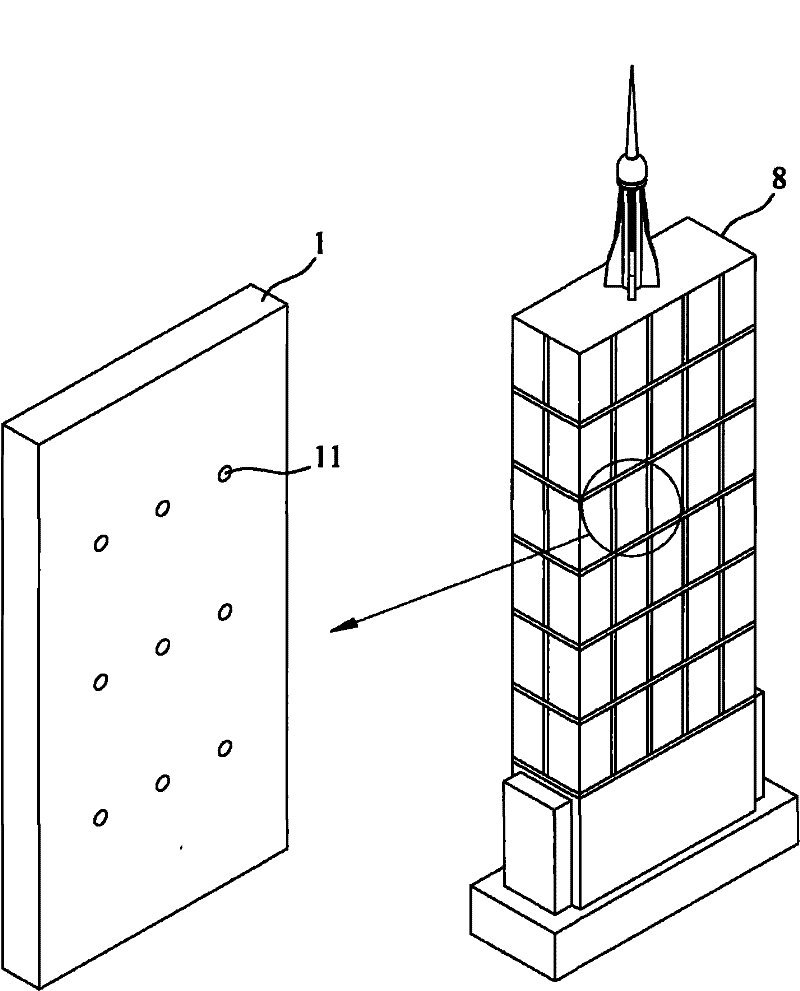

[0014] The present invention is used to construct an energy pellet wall around the board body of a building. The material contained in the energy pellet wall has the characteristics of light weight, firmness, fire prevention, sound insulation and heat insulation at the same time. The construction of the energy pellet wall The method is simple and easy, and after the construction is completed, it has the effects of fire prevention, heat insulation and sound insulation at the same time. It is not necessary to build heat insulation or sound insulation layer by layer like the existing technology, which effectively reduces construction costs and saves energy. The pellet wall is made of waste mud, which is recycled and reused. It is very environmentally friendly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com