Wallboard with opening on lateral edge

A wall panel, unilateral technology, applied in the direction of walls, building components, buildings, etc., can solve the problems that the thermal insulation performance cannot meet the energy-saving requirements, the structure of the wall panel is complex, and the efficiency is low, so as to achieve superior performance and masonry walls The effect of short time and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

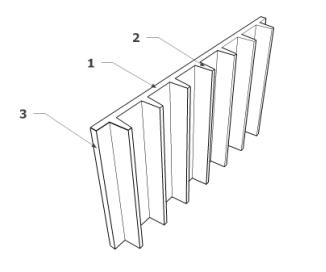

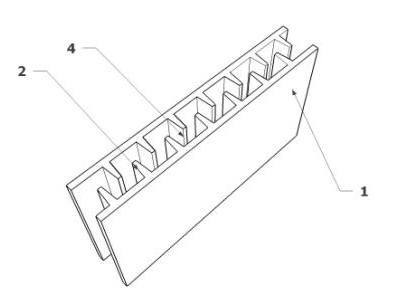

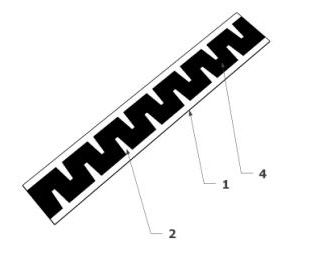

[0016] see figure 1 , figure 2 , image 3 , a single-sided opening wallboard, including a wallboard body 1 provided with variable cross-section cross ribs 2, characterized in that: the variable cross-section cross ribs 2 are arranged on one side of the wall board body 1, and between two closer variable cross-section cross ribs The distance is equal to twice the distance from the variable section cross rib to the top surface of the wallboard, plus the thickness of the mortar joint. When the wallboard body is built into a wall, the inner and outer sides of the wall are firstly built, and the blank space in the middle of the wall is filled. The thermal insulation material, the thickness of the thermal insulation layer and the thermal insulation material are selected according to the actual energy saving needs, so as to improve the thermal insulation and sound insulation performance of the wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com