Fast lifting slip form

A sliding form and formwork technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve problems such as cold joints, unguaranteed construction progress, and long time for slipping formwork to achieve The effect of speeding up the construction progress, solving the quality and progress problems of building construction, and shortening the construction period of concrete forming construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

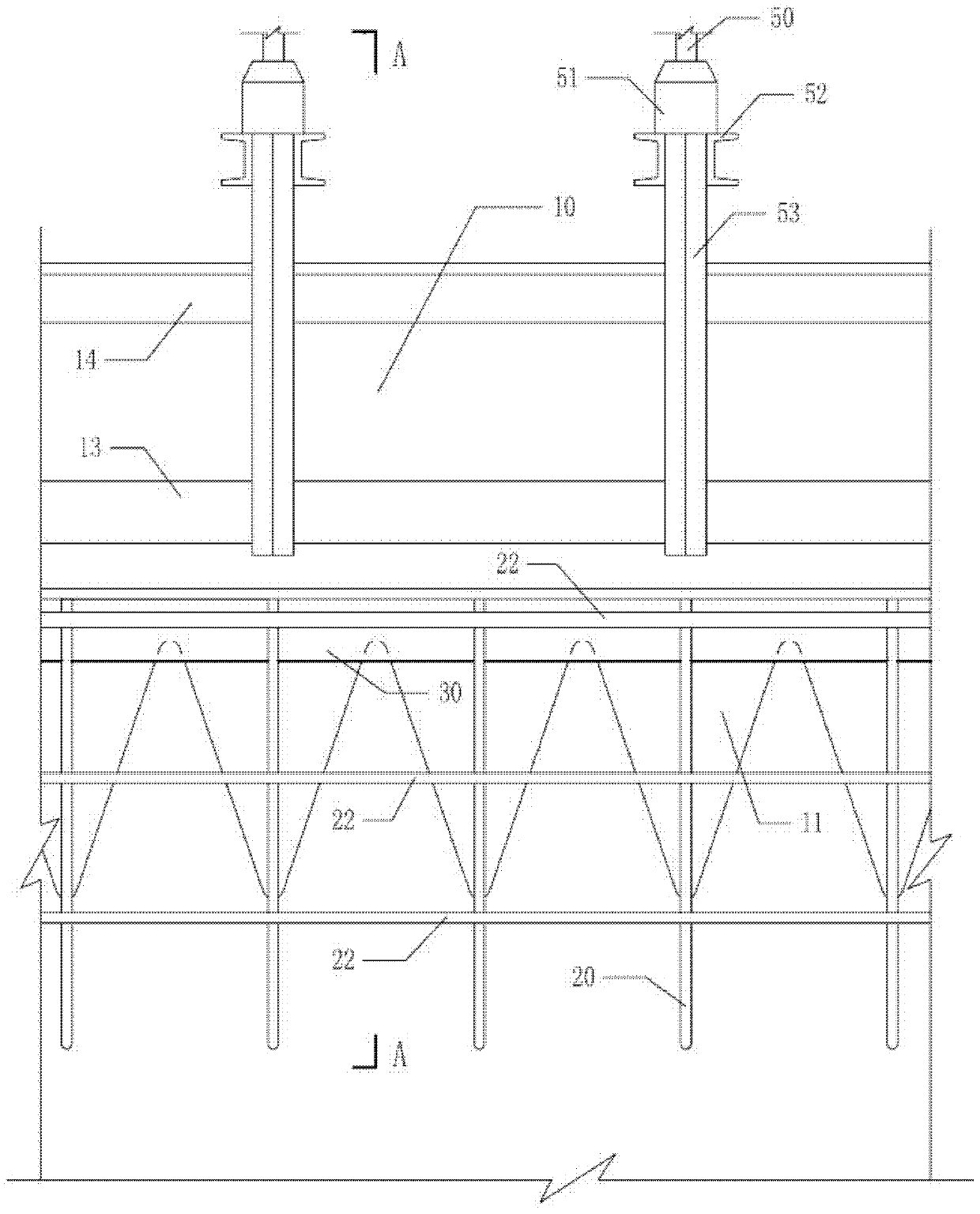

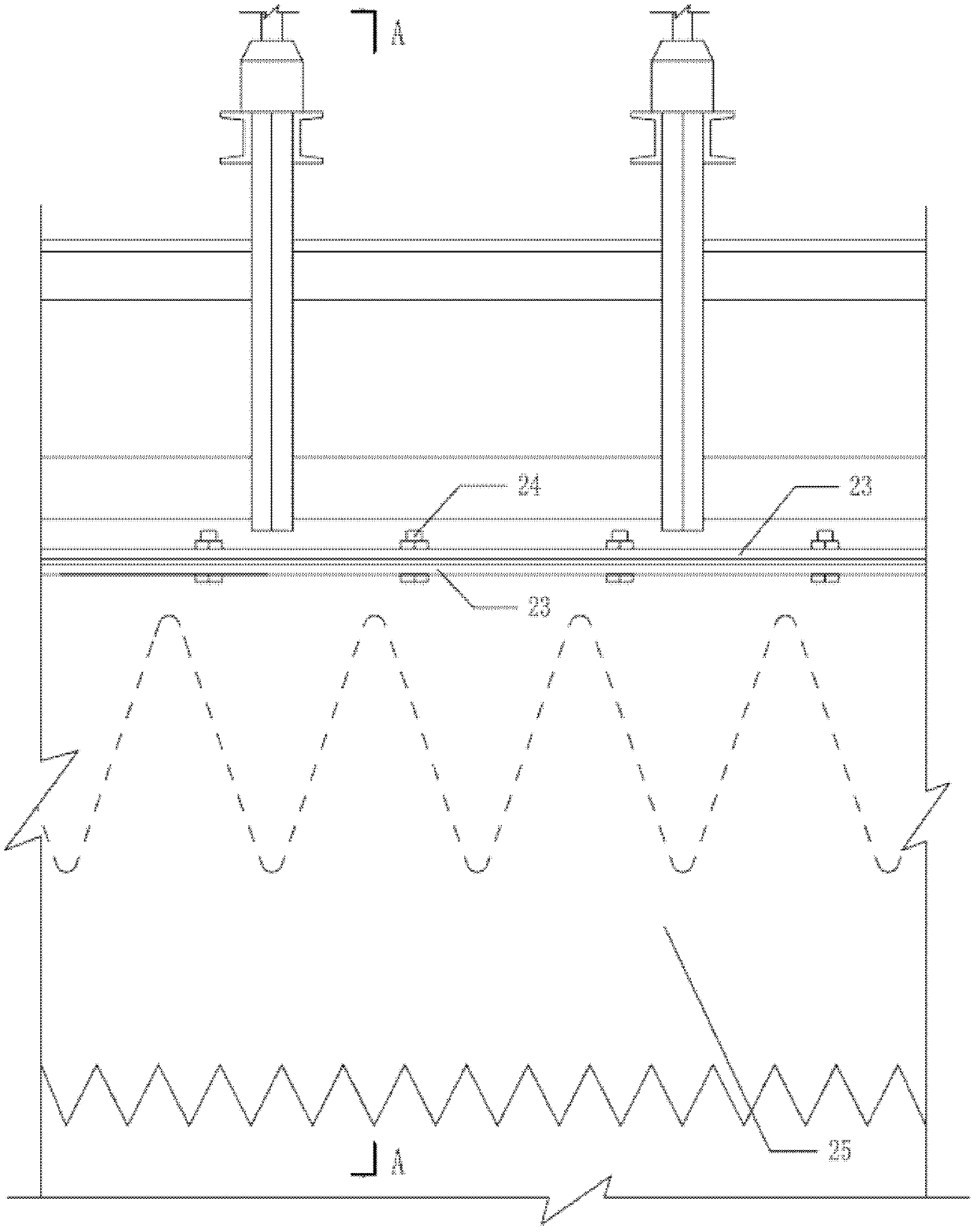

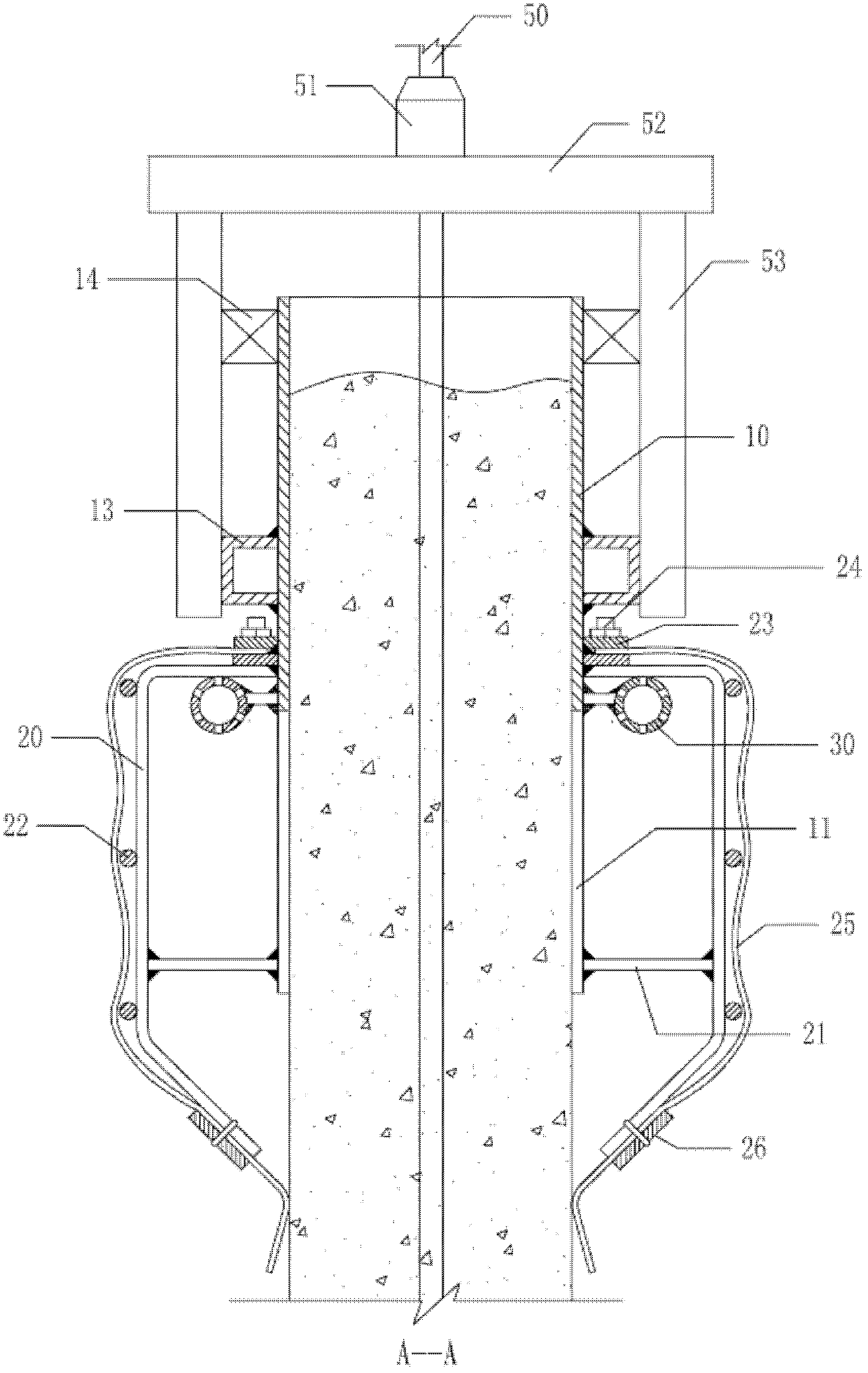

[0014] The rapid lifting sliding form disclosed in the patent application of the present invention includes a formwork, a formwork enclosure and a formwork gantry sliding mechanism, and the formwork is composed of a molded enclosure 10 and a toothed molded enclosure 11 at the bottom of the molded enclosure 10 , it can be integrally made into a formwork with a lower tooth-shaped edge from a piece of coaming material, or a tooth-shaped molded coaming 11 can be fixedly welded under the original rectangular formwork 10, and the tooth shape of the tooth-shaped molded coaming 11 Such as Figure 5 As shown, it can be the wavy shape of the figure (a), the zigzag shape of the figure (c), or the deformed figure (b) based on the figure (c). The tooth shape of the figure (b) is equivalent to the adjacent An extension distance is added between the sawtooth shapes, and the tooth shape can also be other set sinusoidal waveforms and the like. The outer surface of the molded enclosure 10 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com