Electrohydraulic servo bending machine hydraulic system

A hydraulic system and electro-hydraulic servo technology, applied in servo motors, servo motor components, mechanical equipment, etc., can solve the problems of large hydraulic control valve group, low power density ratio, heavy weight, etc., to achieve convenient control and strong versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

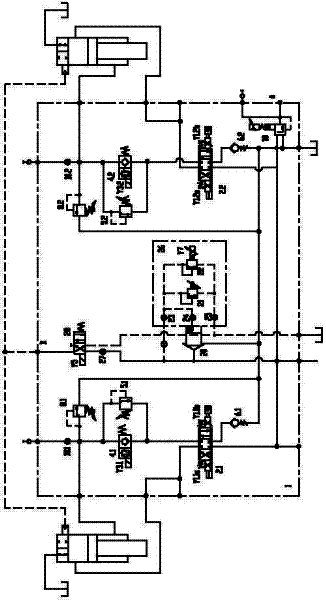

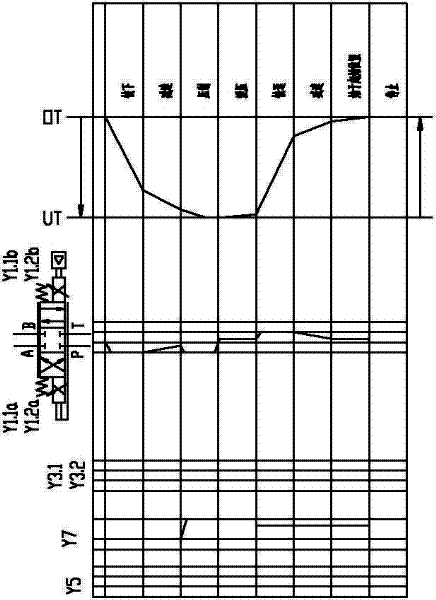

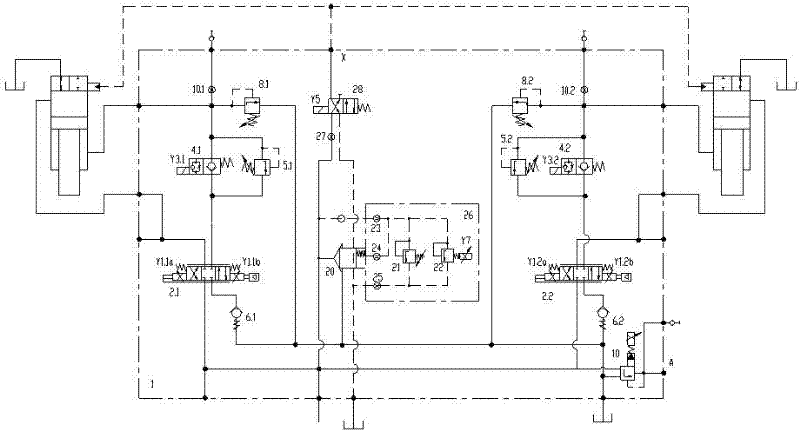

[0014] The technology will be further described below in conjunction with the accompanying drawings.

[0015] see figure 1 As shown, the hydraulic control system consists of:

[0016] 1. Central control block (NC system): It integrates control modules such as system pressure control, oil cylinder synchronous control, and worktable deflection compensation.

[0017] 2. System pressure control: two-way cartridge valve 20, pressure valve 21, proportional pressure valve 22.

[0018] 3. Oil cylinder synchronous control: electromagnetic reversing valve 4.1, 4.2, back pressure valve 5.1, 5.2, lower cavity safety valve 8.1, 8.2, proportional servo valve 2., 2.2.

[0019] 4. In addition, there is an electromagnetic reversing valve 28 and a filling valve to control the filling valve. The A port of the electromagnetic reversing valve 28. If it is a normally closed liquid filling valve, its control port is connected to the B port of the electromagnetic reversing valve 28).

[0020] Pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com