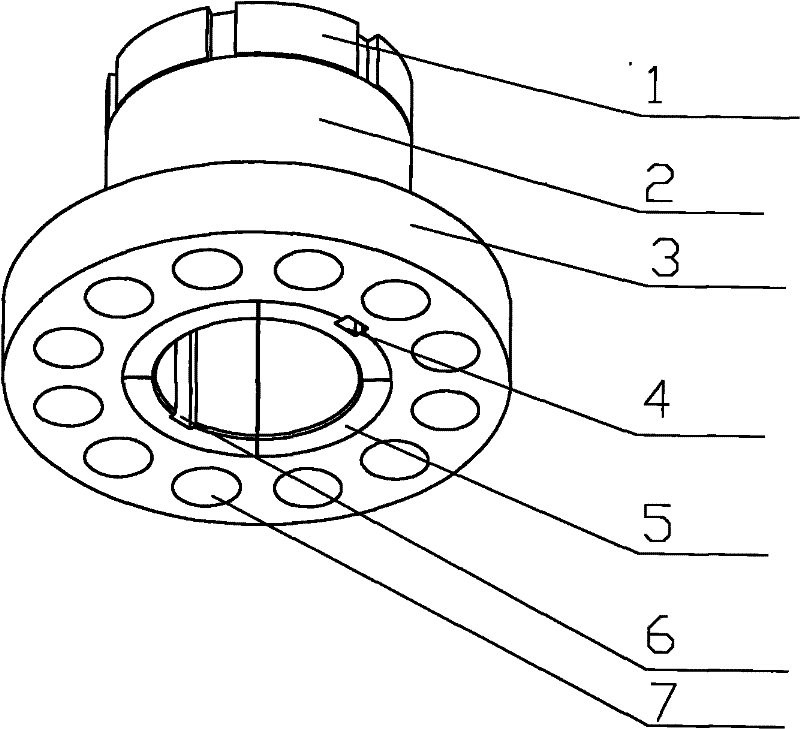

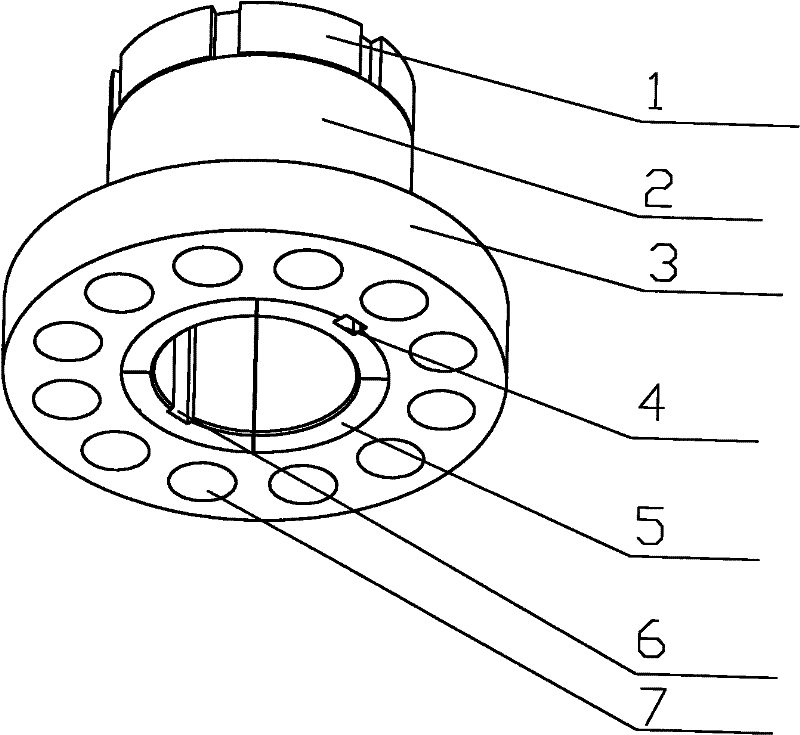

Self-expanding clamp coupling

A coupling and self-expanding technology, applied in couplings, rigid shaft couplings, mechanical equipment, etc., can solve problems such as poor adaptability and inability to install motors, and achieve high production efficiency, convenient clamping and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0009] As shown in the attached figure, the self-expanding clamping coupling includes 4 expansion pieces 5, the gap between the expansion pieces is small, generally set between 0.05-0.1mm, and the combination of expansion pieces 5 forms a tapered The cylindrical shape is installed in the base 2, and the expansion piece is closely matched with the taper of the base. One of the expansion pieces is connected with the base through the flat key 4 to ensure the circumferential position accuracy of the expansion piece in the base. A keyway 6 is set on the circular surface, and the rear end of the expansion piece protrudes from the base and is equipped with a thread, on which a clamping nut 1 is screwed. Since the mating surfaces of the base and the expansion piece are tapered, the expansion piece moves axially At the same time, it will produce radial contracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com