Rotary water distributor

A technology of rotating water distributor and water distributor, applied in the direction of water shower cooler, heat exchanger type, direct contact heat exchanger, etc., can solve the problem of weakening the uniformity and integrity of water film, compressed air pressure and air It can avoid problems such as quantity decline, and achieve the effect of avoiding uniformity and integrity, stable operation and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

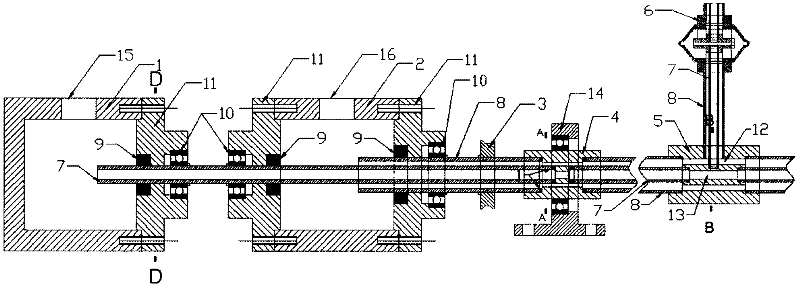

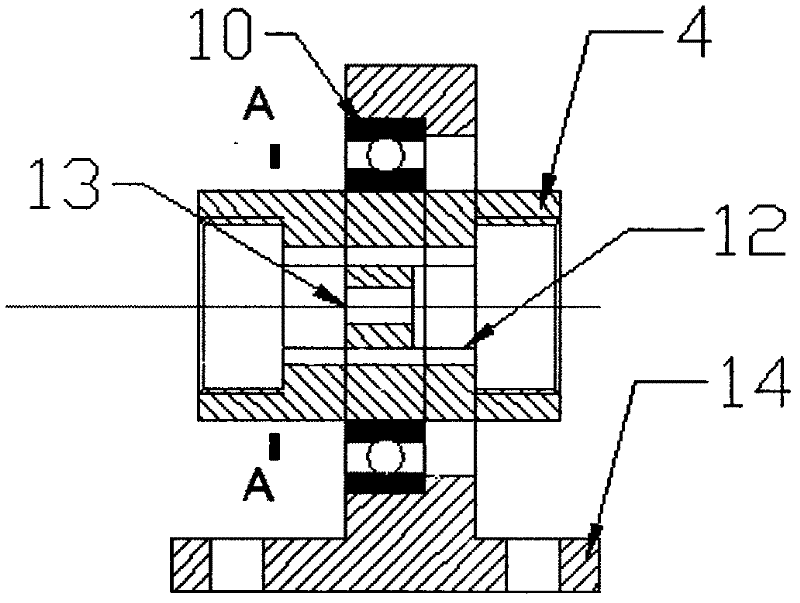

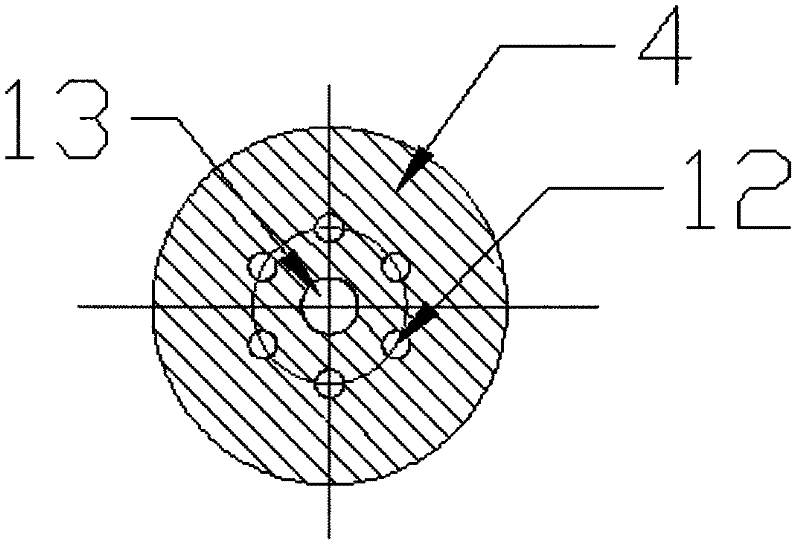

[0019] The water distributor of the present invention is composed of a water distribution device, a compressed air distribution device, a transmission device, a pipeline connection device, a distribution device, a nozzle, a water transmission and distribution pipeline and a compressed air transmission and distribution pipeline. figure 1 As shown, the distributing device and the nozzle are connected through the water transmission and distribution pipeline and the compressed air transmission and distribution pipeline to form a transmission and distribution branch pipe. On each transmission and distribution branch pipe, the nozzles are connected in series through the water transmission and distribution pipeline and the compressed air transmission and distribution pipeline to form a Multiple water distribution points; multiple transmission and distribution branch pipes of the water distributor are on the main transmission and distribution pipeline composed of water transmission and ...

Embodiment 2

[0027] When the atomizing substance of the water distributor of the present invention is only water, the water distributor is composed of a water distribution device, a transmission device, a pipeline connection device, a distribution device, a nozzle and a water distribution pipeline, as shown in the attached Figure 9 As shown, the distribution device and the nozzles are connected through water distribution pipes to form a distribution branch pipe. On each distribution branch pipe, the nozzles are connected in series through water distribution pipes to form multiple water distribution points; The transmission and distribution branch pipes are connected in parallel to the transmission and distribution branch pipe system on the transmission and distribution main pipes composed of water transmission and distribution pipes; The distribution device enters the nozzle for atomization through the water distribution pipe, and the electric motor drives the water distributor to rotate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com