Dynamic monitoring system device for tailing dam body by three-dimensional laser scanning

A three-dimensional laser, dynamic monitoring technology, applied in measuring devices, measuring instruments, mapping and navigation, etc., can solve the problems of low cost, fast single scanning speed, high measurement accuracy, and achieve high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

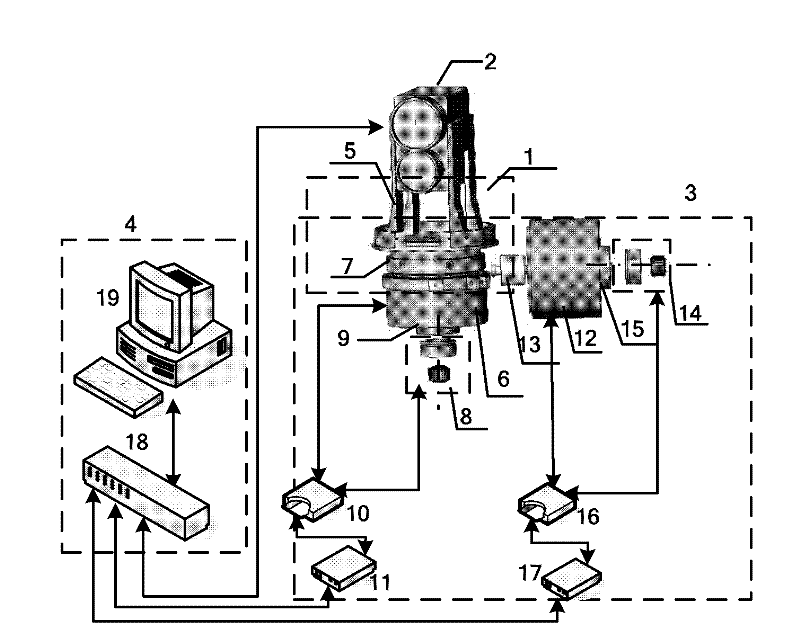

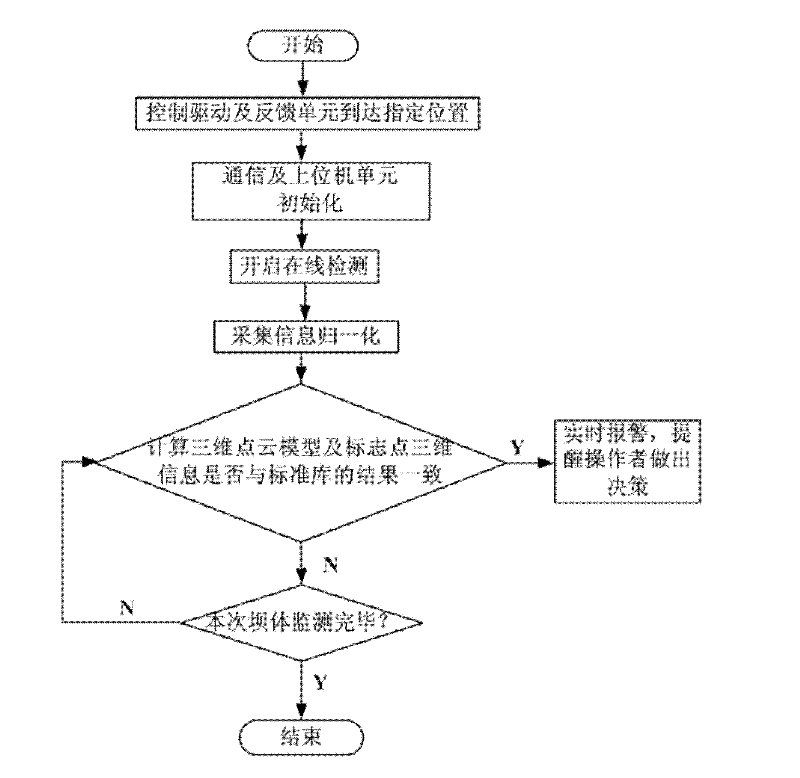

[0045] Such as figure 1 As shown, the three-dimensional laser scanning tailings dam dynamic monitoring system device of the present invention includes: a mechanical unit 1, a laser data acquisition unit 2, a control drive and feedback unit 3, a communication and a host computer unit 4, wherein

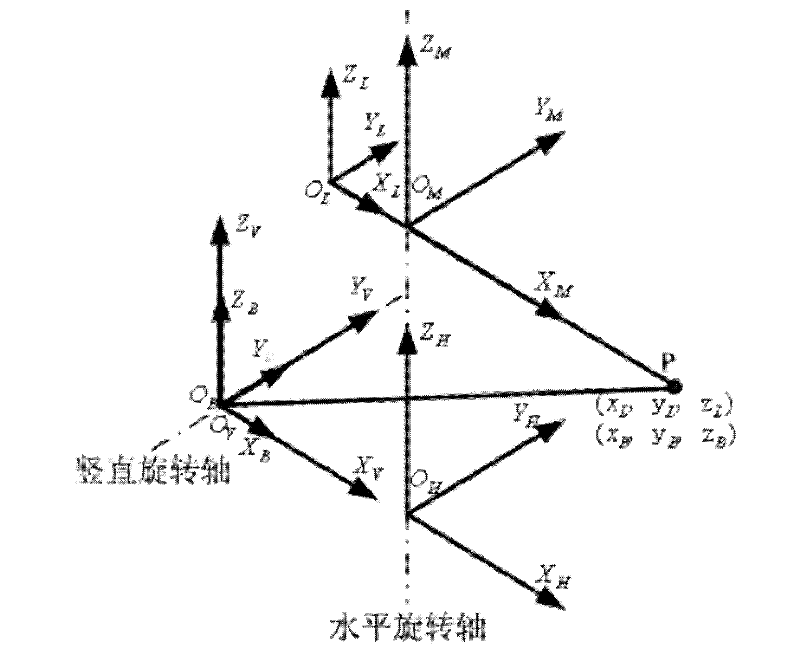

[0046] The mechanical unit 1 is used to connect the laser data acquisition unit 2 with the horizontal direction motor 6 and the vertical direction motor 12 to realize the horizontal and vertical direction scanning of the laser data acquisition unit 2; The direction motor moves synchronously with the fixation of the horizontal resolver connection device 9 , and the vertical resolver 14 and the vertical motor 12 move synchronously with the fixation of the vertical motor and the vertical resolver connection device 15 .

[0047] The laser data acquisition unit 2 can obtain the polar radius information of the ground object point scene in real time. Driven by the horizontal direction motor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power | aaaaa | aaaaa |

| Electric current | aaaaa | aaaaa |

| Power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com