Diagenesis simulation experimental apparatus

A technology for simulating experimental devices and diagenesis. It is used in measurement devices, material inspection products, suspensions and porous material analysis. It can solve problems such as rubber creep, low technical indicators, and difficulty in adapting to acid and alkali corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

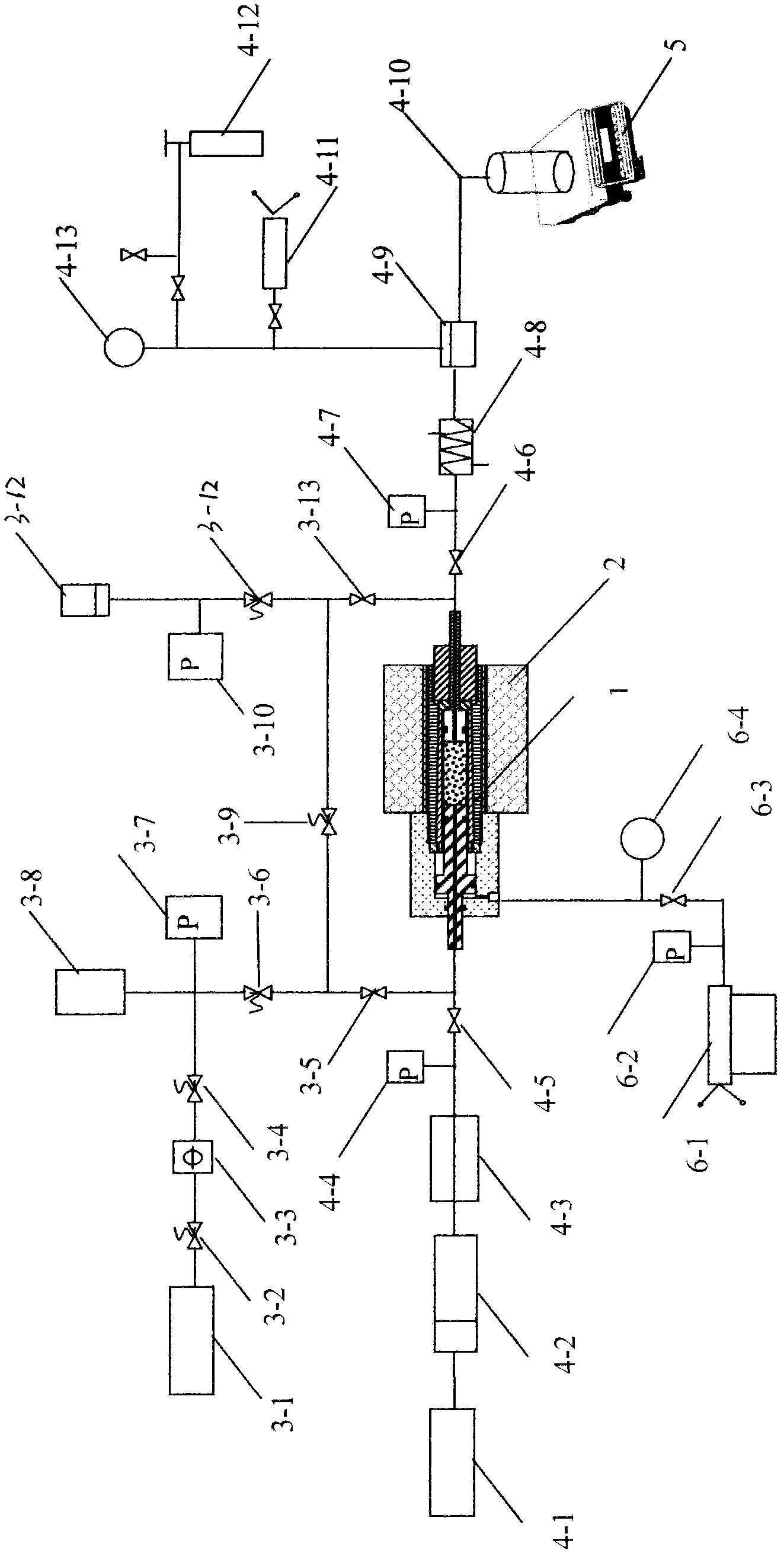

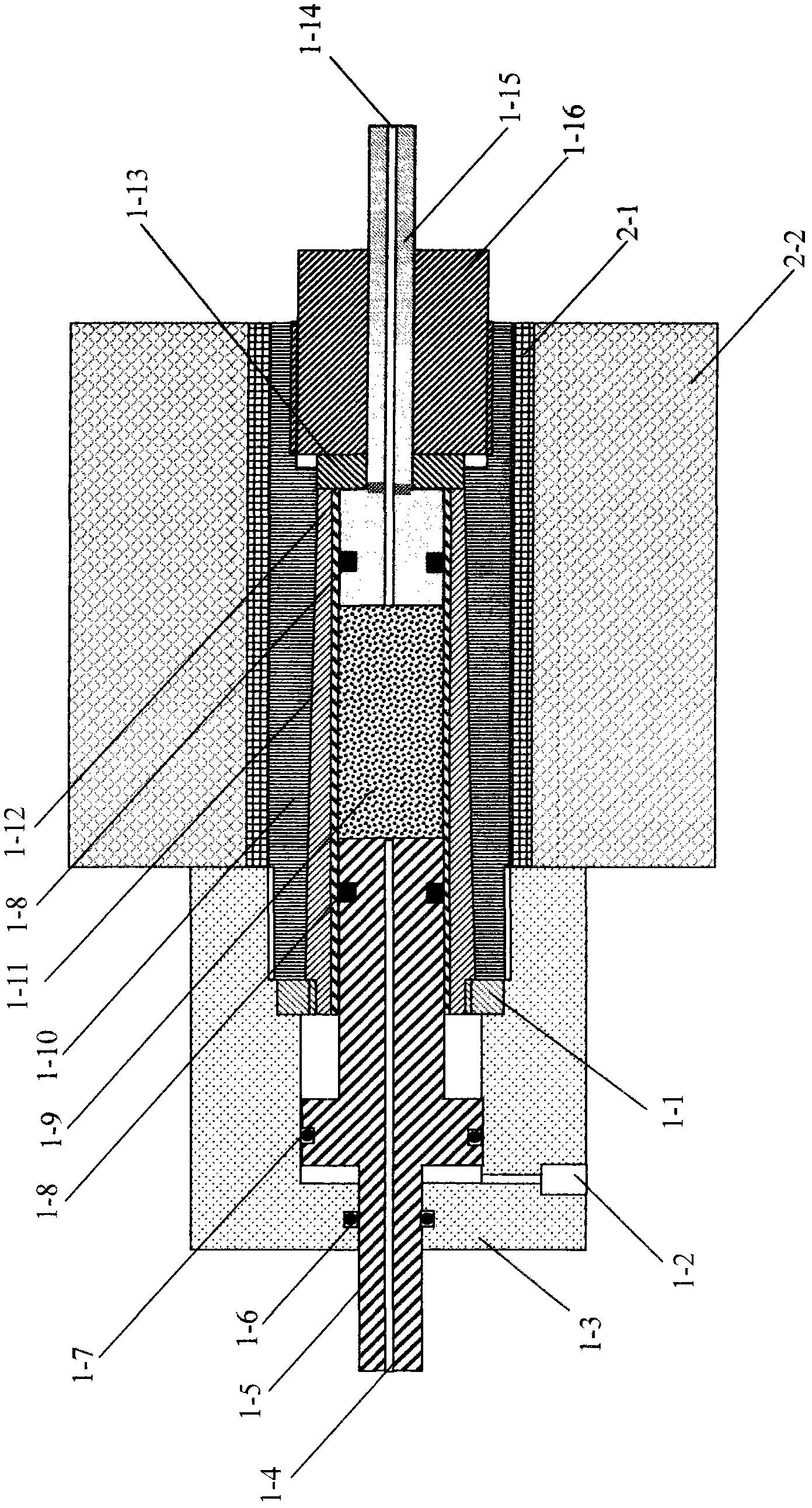

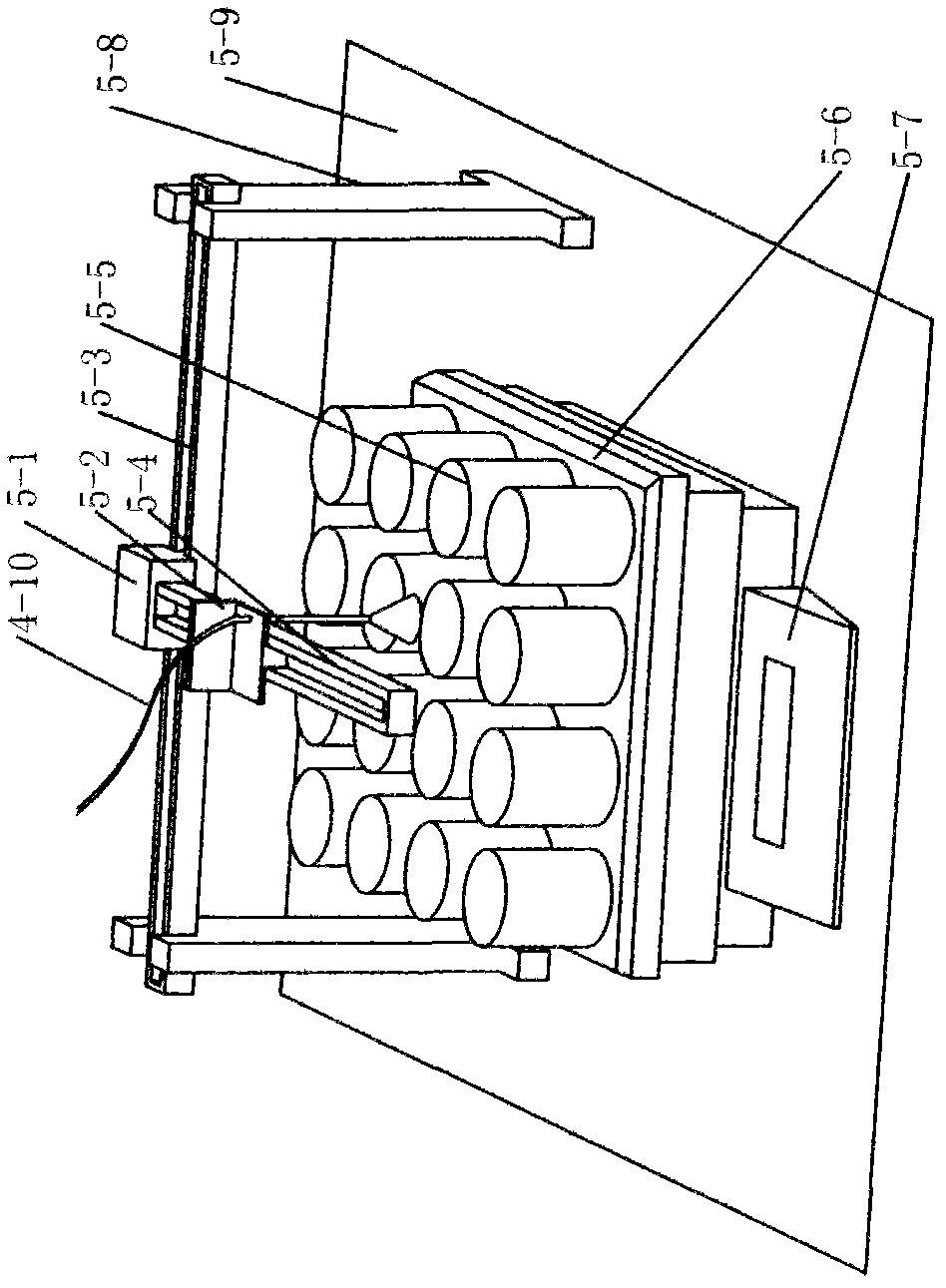

[0030]The present invention includes a core clamping mechanism 1, a heating mechanism 2, a gas porosity and permeability measurement process, a liquid injection and liquid permeability testing process, an automatic continuous metering and sampling mechanism 5 for outlet fluid, an overlying pressure pressurization control mechanism, a fluid Physical property detection mechanism, data acquisition calculation and automatic control mechanism. The inlets 1-4 and outlets 1-14 of the core holding mechanism 1 are respectively connected to the gas porosity, permeability measurement process, liquid injection and liquid permeability testing process; the core holding mechanism 1 is surrounded by a heating mechanism 2, The overlying pressure injection port 1-2 of the core clamping mechanism 1 is connected to the overlying pressure pressurization control mechanism, and the outlet 4-10 of the liquid injection and liquid permeability testing process is connected to the outlet fluid automatic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com