Wafer defect defection method and system

A detection method and defect technology, which are applied in the directions of optical testing defects/defects, semiconductor/solid-state device testing/measurement, etc., can solve problems such as methods and systems for determining the root cause of defects in non-defective wafers, and achieve product yield, Provides the effect of productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

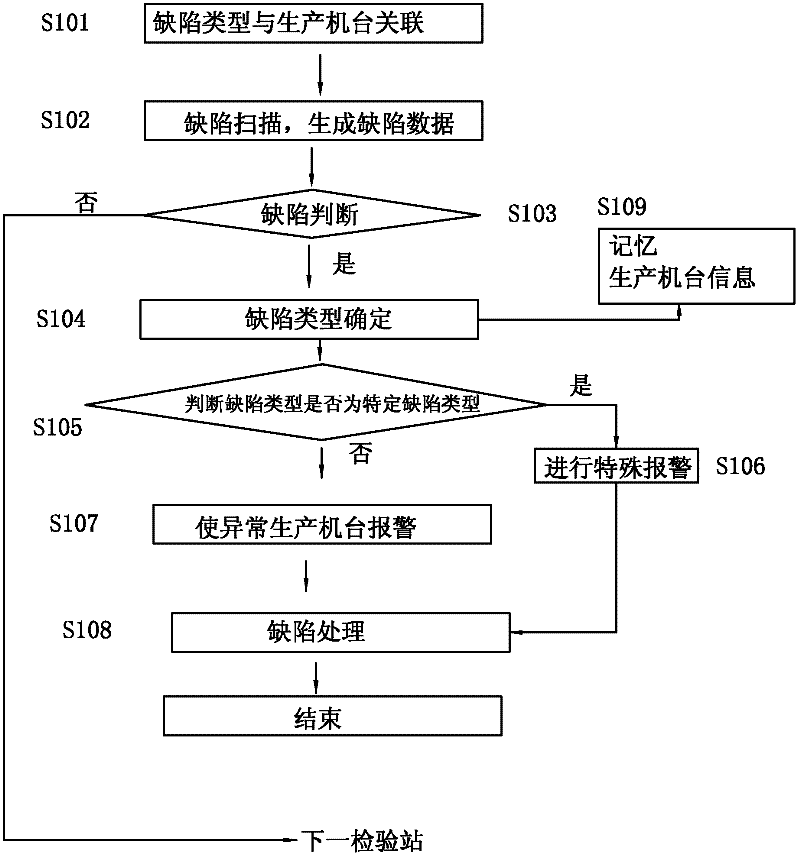

[0024] Hereinafter, specific embodiments of the present invention will be described in detail based on the drawings. The specific embodiments described here are for illustration only, and are not intended to limit the present invention.

[0025] As is well known, a wafer W which is a raw material of an IC device is manufactured through a plurality of processes such as etching and doping. The above-mentioned etching, doping and other processes are carried out on the production machine. The apparatus for processing the wafer W includes a production machine having a reaction chamber for performing the above-mentioned processing, and a robot for transferring the wafer W.

[0026] According to the number of different reaction chambers, the production machines can be divided into By1 group production machines with one reaction chamber, By2 group production machines with two reaction chambers, By3 group production machines with 3 reaction chambers, By4 group of production machines ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com