Compensation control circuit and method for direct current converter

A DC converter, compensation control technology, applied in electrical components, output power conversion devices, etc., can solve problems such as sub-harmonic oscillation, achieve fast dynamic response, ensure dynamic response, and not easy to oscillate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] refer to Figure 4 , which is a schematic structural diagram of the first embodiment of the compensation control circuit of the DC converter according to the present invention; the topology structure of the main circuit is a step-down DC converter as an example for illustration, the compensation control circuit of the DC converter include:

[0047] output voltage feedback circuit, which receives the output voltage of the main circuit V o , and output an output voltage feedback signal FB;

[0048] an inductor current sampling circuit, which samples the inductor current in the main circuit to output a sampled current signal;

[0049] The slope signal generating circuit generates a slope signal;

[0050] The first control unit receives the output voltage feedback signal FB, the signal obtained by adding the sampling current signal and the ramp signal, and the first reference voltage signal V ref1 , and compare to output the first control signal;

[0051] A second cont...

Embodiment 2

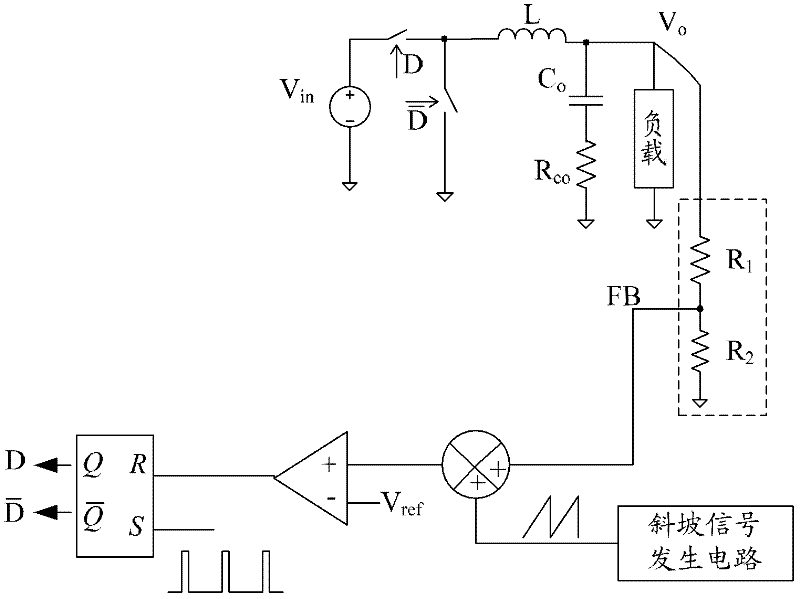

[0056] refer to Figure 5 , is a schematic structural diagram of a compensation control circuit for a DC converter provided by the present invention, where the topology of the main circuit is still a step-down DC converter as an example for illustration.

[0057] The output voltage feedback circuit described in this embodiment includes a resistor R 1 and R 2 The voltage divider circuit composed of series, the output voltage V of the main circuit o After the voltage is divided by the voltage divider circuit, the resistor R 1 and R 2 The common connection point of the outputs an output voltage feedback signal FB.

[0058] The inductor current sampling circuit can perform analog sampling on a fixed time period in the rising stage or falling stage of the inductor current in each switching cycle, and can also perform analog sampling on a fixed time period in the rising stage or falling stage of the inductor current in each switching cycle Points for digital sampling, which can...

Embodiment 3

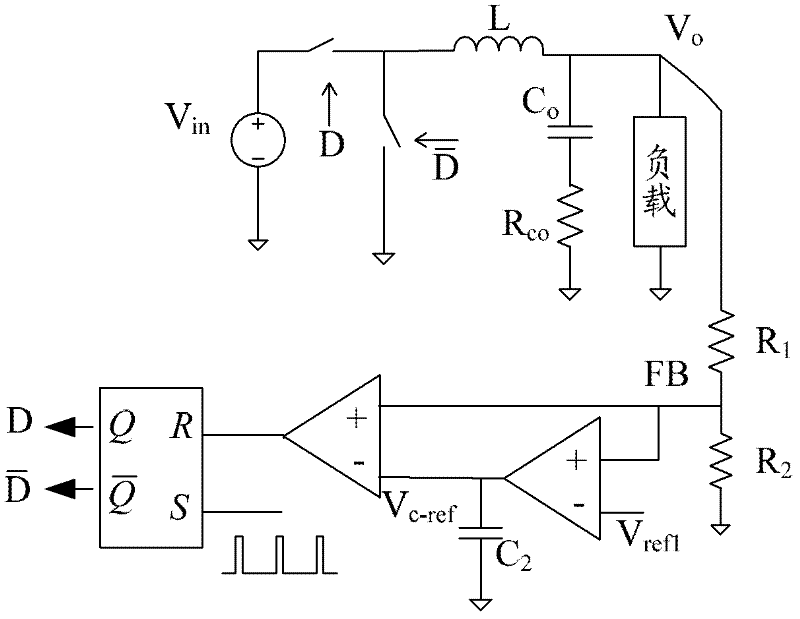

[0065] Figure 5 In the illustrated embodiment the first reference voltage signal V ref1 For a preset reference voltage signal, it is also possible to use Figure 7 The structure in the shown embodiment: the output voltage feedback signal FB and a preset reference voltage signal V ref2 The compared error amplification signal is passed through the capacitor C 2 The reference voltage signal V obtained after compensation c-ref as the first reference voltage signal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com