Casting method for hub

A wheel hub and casting machine technology, applied in the direction of casting molding equipment, casting molds, casting mold components, etc., can solve the problems of shortening the service life of the mold, shrinkage, and prolonging the production cycle, so as to prolong the service life, eliminate the influence of fatigue, The effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

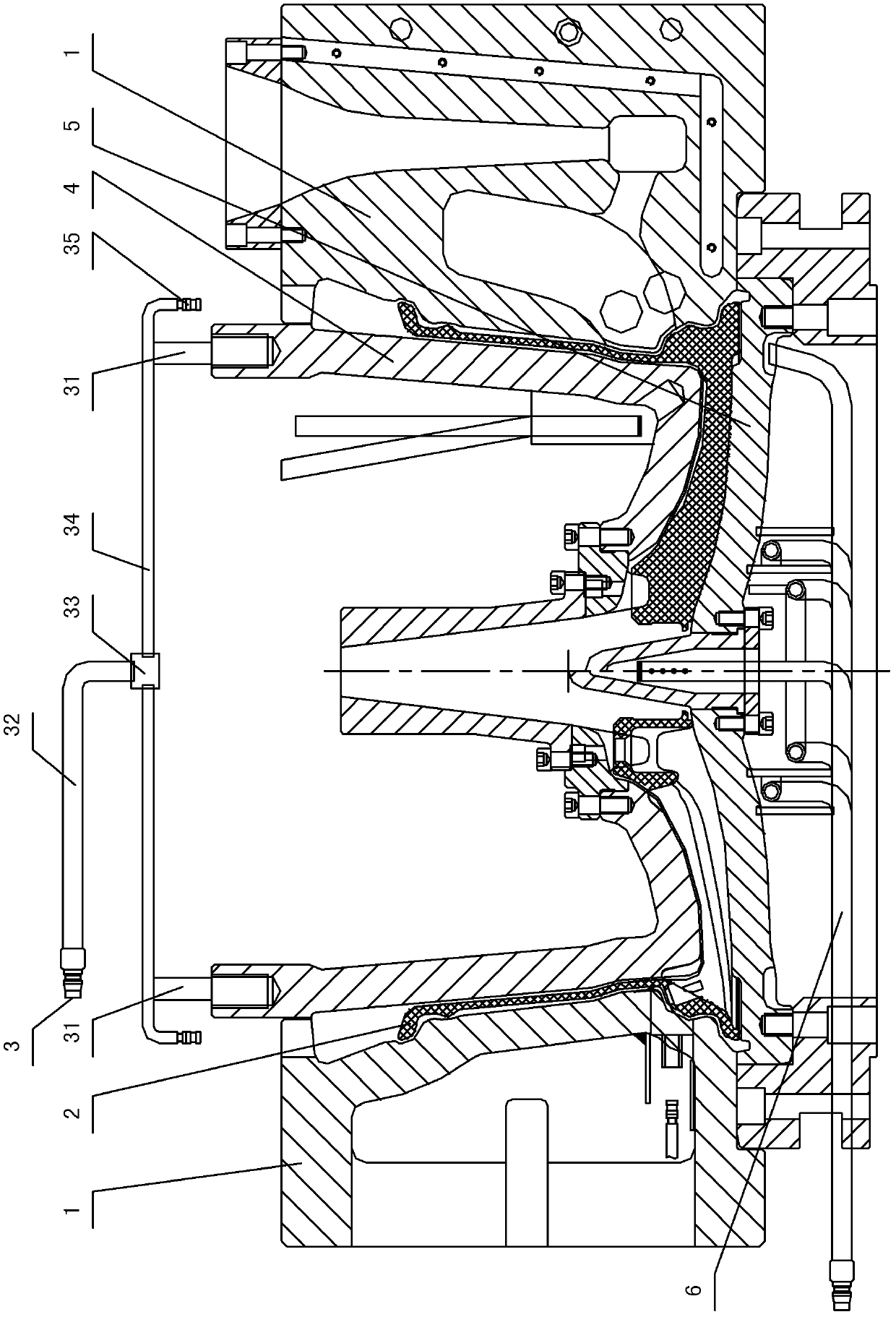

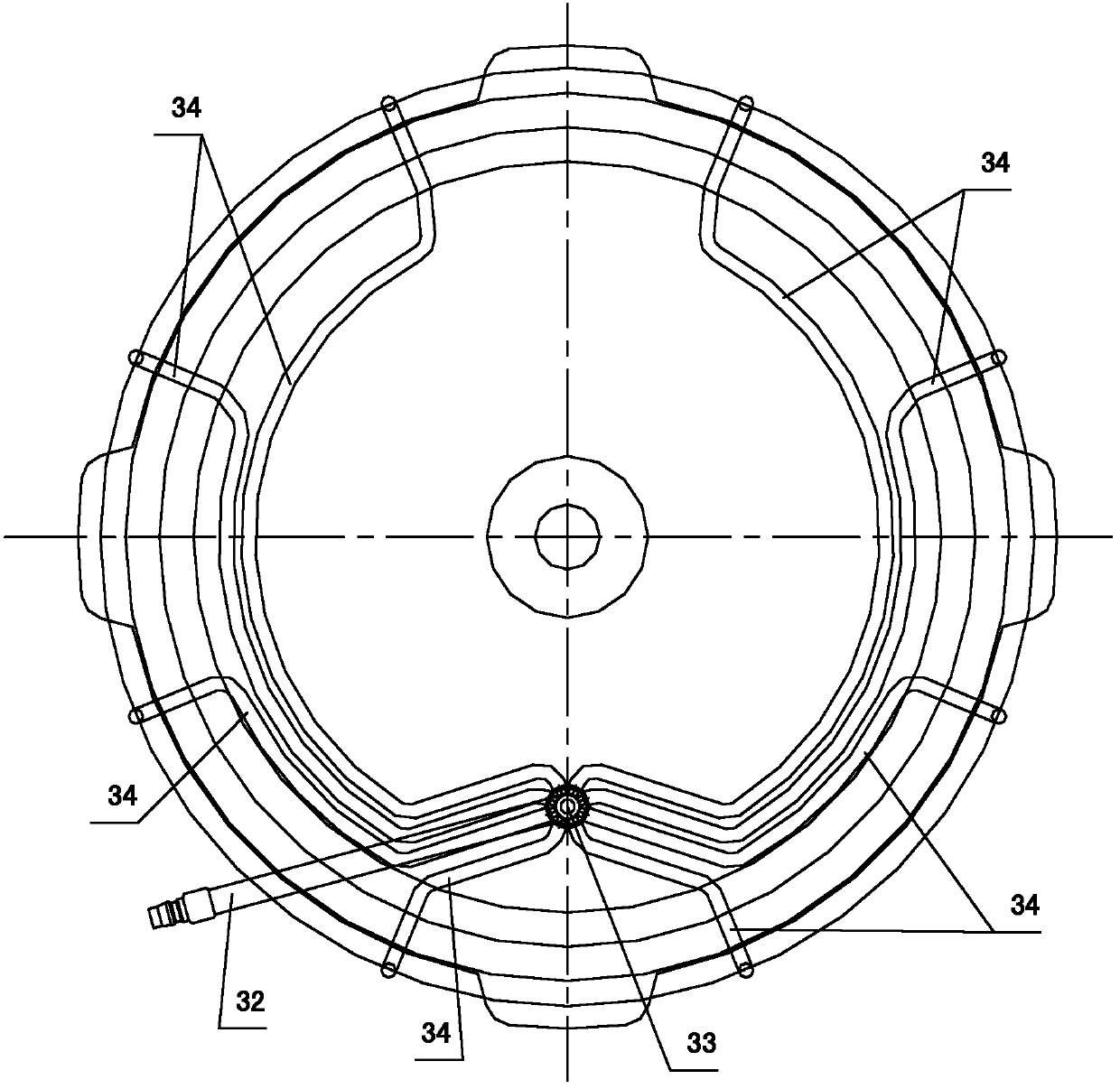

[0022] Depend on figure 1 with figure 2 The shown structural representation of the casting method of the wheel hub of the present invention and the water mist cooling device used therein shows that the casting method of the wheel hub comprises the following steps:

[0023] 1) The mold of the wheel hub is composed of upper mold 4, lower mold 5 and side mold 1. After installing the water cooling device 6 under the lower mold 5, fix the lower mold 5 on the casting machine, and then install the side mold 1 and upper mold 4. Then a water mist cooling device 3 is installed on the top of the upper mold 4;

[0024] 2) After installing the mold on the casting machine, pour liquid aluminum water into the cavity of the mold for filling;

[0025] 3) After the casting is completed, the water cooling device 6 is used for cooling. When the hub c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com