Method for designing and evaluating dense-grading large stone asphalt mixture

A technology of asphalt mixture and evaluation method, which is applied in the field of highway engineering construction and maintenance, to achieve the effect of enhancing road performance and facilitating promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] LSAM is used in the pavement of asphalt pavement. A certain expressway is designed as a two-way four-lane expressway, which is an expressway in mountainous areas. The extreme maximum temperature in the past 20 years is 39.8°C, and the extreme minimum temperature is -19.5°C. The design cumulative number of axle loads = 2.680×10 6 Time / per lane, the proportion of large trucks in the traffic composition accounts for 40% to 50%, and it is expected to often encounter slow traffic conditions. The LSAM coarse type is used as the middle layer to strengthen the high temperature resistance to permanent deformation and load fatigue resistance. According to the traffic The base asphalt of PG 58-22 is selected for volume, driving speed and air temperature, and the design thickness is 10cm. The designed LSAM parameters are as follows:

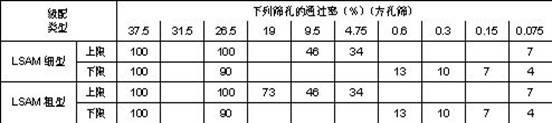

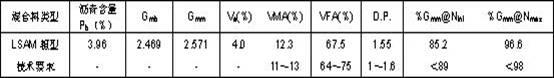

[0024] LSAM mix design results

[0025]

[0026] Synthetic grading test parameter values

[0027]

[0028] Performance Analysis of Asph...

Embodiment 2

[0033] LSAM is used in the pavement of asphalt pavement. The pavement renovation of an expressway is designed as a two-way four-lane expressway, which is an expressway in a mountainous area, with an average slope of more than 4%, an extreme maximum temperature of 43°C, and an extreme minimum temperature of -25.8°C. Design accumulative number of axle loads 5.66×10 8 Time / per lane, the proportion of large trucks in the traffic composition accounts for about 45%, and it is expected to often encounter slow traffic conditions. The LSAM thin layer is used as the middle layer to strengthen the high temperature resistance to permanent deformation and load fatigue resistance. According to traffic volume, PG 70-22 modified asphalt is selected for driving speed and air temperature, and the design thickness is 8cm. The designed LSAM parameters are as follows:

[0034] LSAM mix design results

[0035]

[0036] Synthetic grading test parameter values

[0037]

[0038] Perform...

Embodiment 3

[0043] LSAM is used in the pavement of asphalt pavement. The pavement of a certain expressway is designed as a two-way four-lane highway, which is a plain area expressway, with an extreme maximum temperature of 37.6°C and an extreme minimum temperature of -28.6°C. The design accumulative number of axle loads is 5.77×10 7 Time / per lane, the proportion of large trucks in the traffic composition accounts for about 40%, and it is expected to often encounter slow traffic conditions. The LSAM thin layer is used as the lower layer to strengthen the high temperature resistance to permanent deformation and load fatigue resistance. According to traffic volume, The driving speed and air temperature select PG 64-22 base asphalt, the design thickness is 8cm, and the designed LSAM parameters are as follows:

[0044] LSAM mix design results

[0045]

[0046] Synthetic grading test parameter values

[0047]

[0048] Performance Analysis of Asphalt Mixture Pavement

[0049]

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com