Branched well screen pipe anchoring compensation device

A compensation device and a technology for branch wells, which are used in wellbore/well components, production fluids, earth-moving drilling, etc., which can solve the problem of failure to increase single well production, shorten the service life of branch wells, and screen tubes that cannot be supported. problems such as borehole wall and sand control, to achieve the effect of prolonging the service life and improving the production of a single well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

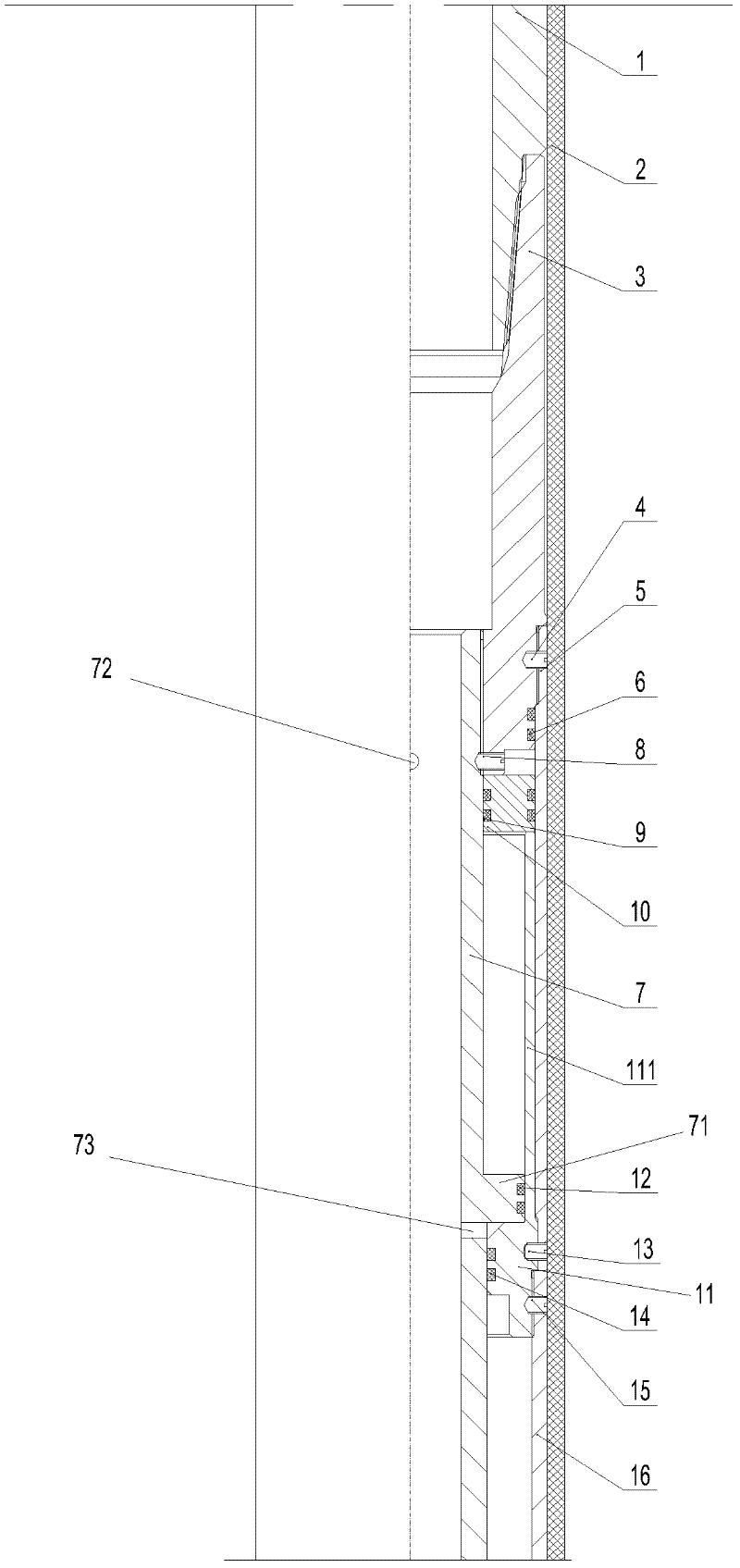

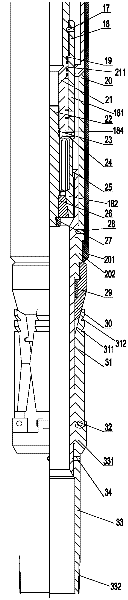

[0031] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0032] Such as figure 1 , Figure 1A , Figure 1B As shown, the present invention provides a lateral well screen anchor compensation device 100, the anchor compensation device 100 includes an inner pipe 7, an outer flange 71 is provided in the middle of the inner pipe 7; an upper joint 3 is externally connected to the upper end of the inner pipe 7 , in this embodiment, the upper joint 3 is threadedly connected with the inner pipe 7 and fixed by the second anti-rotation pin 8, the upper end of the upper joint 3 is internally connected with the drill pipe pup joint 1; the lower end of the upper joint 3 is externally connected with a liquid cylinder jacket Pipe 5, in this embodiment, the upper joint 3 and the outer casing 5 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com