Contactless electronic ignition system

An electronic ignition and non-contact technology, applied in spark ignition controllers, engine ignition, induction energy storage devices, etc., to achieve the effects of increasing primary current, improving ignition performance, and increasing secondary voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

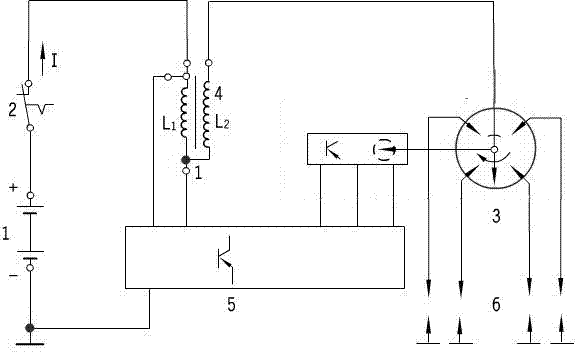

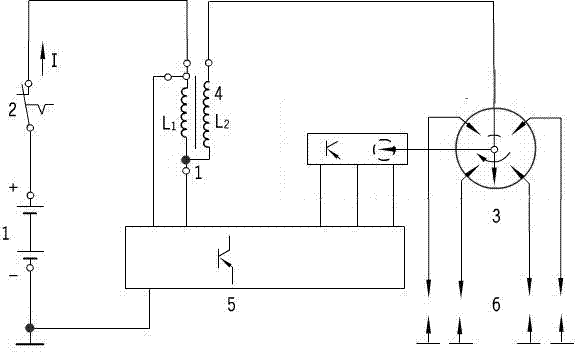

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0013] A non-contact electronic ignition system, including a power supply, an ignition controller, an ignition signal generator, an ignition coil, a spark plug and an ignition switch, is characterized in that: a distributor circuit is integrated on the circuit board of the ignition signal generator, The ignition signal generator is connected with the spark plug and the secondary winding of the ignition coil through wires, and the ignition controller is connected and controlled between the ignition signal generator and the primary winding of the ignition coil; the ignition signal generator with a distributor receives non-electric The piston position signal is converted into a pulse electrical signal and sent to the ignition controller.

[0014] combine figure 1 , turn on the ignition switch, when the ignition signal generator with distributor s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com