Automobile continuously variable transmission (CVT) system, and design and control methods thereof

A technology of continuously variable speed and continuously variable transmission, which is applied in the direction of mechanical equipment, gear transmission devices, fluid transmission devices, etc., and can solve the problems of easy damage to the transmission belt, poor use effect, large load, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

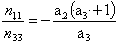

Method used

Image

Examples

Embodiment 2

[0111] In this embodiment, the difference from Embodiment 1 is that the hydraulic torque divider is an axial flow hydraulic torque divider. combine Figure 8 and Figure 9 , the power input element in the axial-flow hydraulic torque divider is a pump wheel 2 10-1 driven by the automobile engine 17 to continuously rotate and pump the working fluid axially while continuously rotating The front side of the pump wheel 2 10-1 is coaxially equipped with a drive shaft 2, and the drive shaft 2 is connected with the power output shaft of the automobile engine 17; The first hydraulic transmission part is the turbine three 10-2 located directly behind the pump wheel two 10-1, and the working fluid pumped from the pump wheel two 10-1 directly and evenly impacts on the turbine three 10-2 and accordingly drives the turbine three 10-2 performs continuous rotation, the hydraulic transmission member 2 in the centrifugal hydraulic torque divider is the turbine 4 10-4 located directly behind t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com