Elastic structure polytetrafluoroethylene oil seal

A technology of polytetrafluoroethylene and elastic structure, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of creep elasticity and poor static sealing performance, and achieve the effect of improving dynamic sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

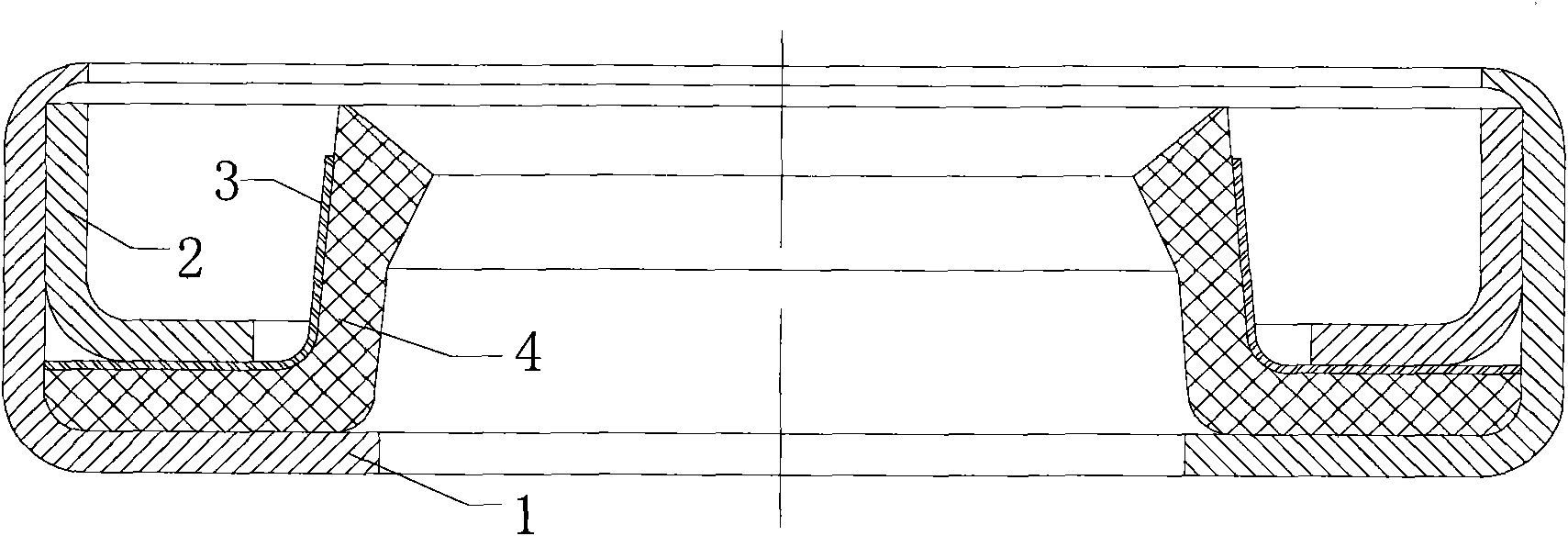

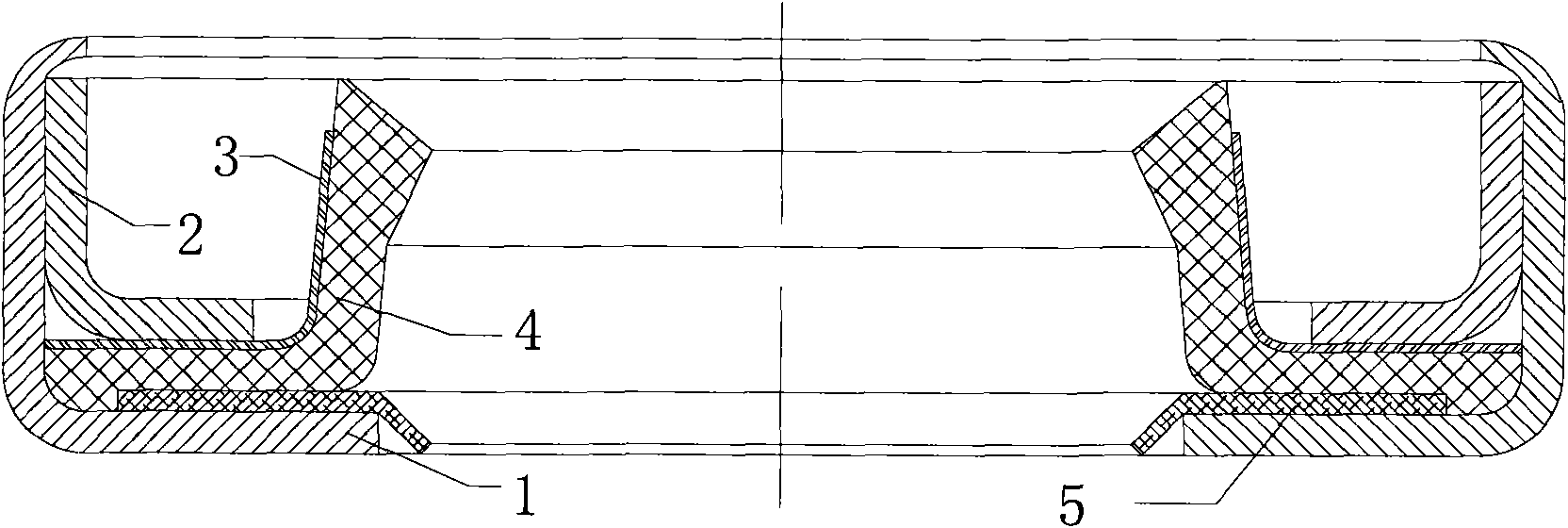

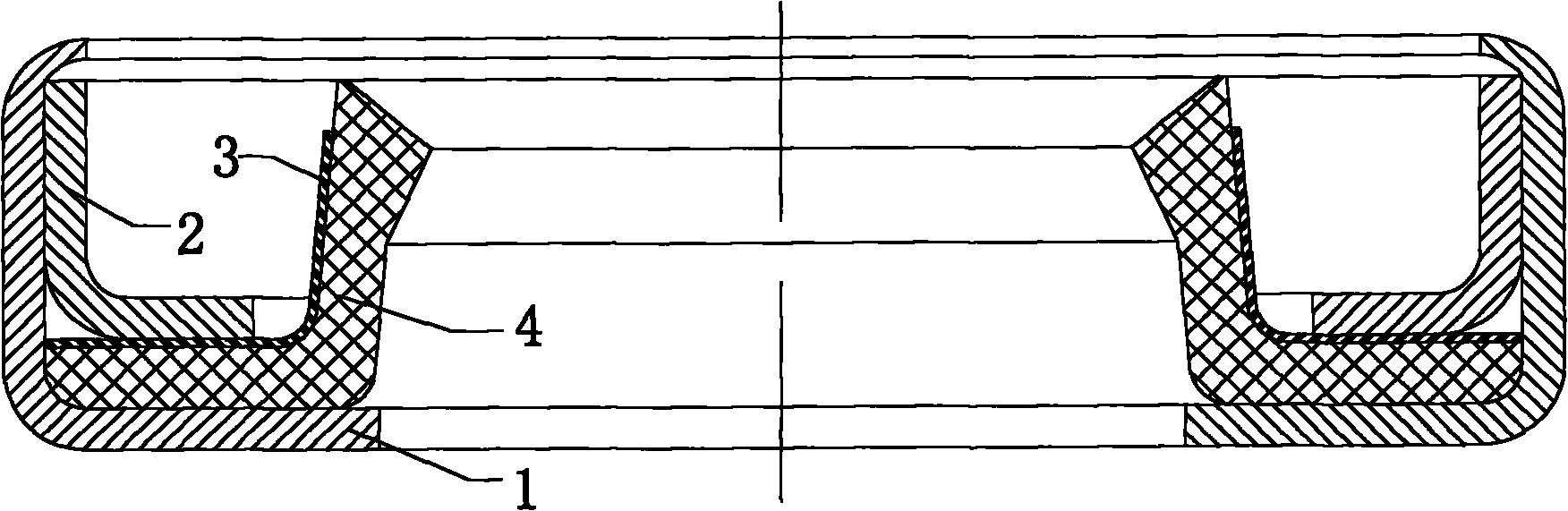

[0021] The design reference standard of the oil seal frame (1, 2) is GB / T9877.3-1988 ("Rotary Shaft Lip Seal Ring Structural Dimensions Series Part III: Assembled Rotary Shaft Lip Seal Ring").

[0022] Processing technology of oil seal frame (1, 2):

[0023] Chipping the steel plate to obtain the ring piece→rolling the ring piece→machining→external skeleton (1);

[0024] Chip steel plate to get the ring part → roll forming the ring part → inner skeleton (2)

[0025] Spring sheet (3) processing technology: punching tooling → wire cutting preforming → stamping forming. Of course, other common hardware processing techniques such as punching and forming can also be used. In addition, other similar leaf spring structures can also be used to achieve a similar effect to provide radial force for the oil seal.

[0026] The processing technology of the sealing ring (4): polytetrafluoroethylene powder, filler → sintering → tube material or bar of polytetrafluoroethylene composite mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com