Method for producing tea gum

A production method and a chewing gum technology, applied in the field of chewing gum, can solve the problems such as the inability to exert the health care effect of tea, the loss of fragrance, and the inability to make up for the spices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

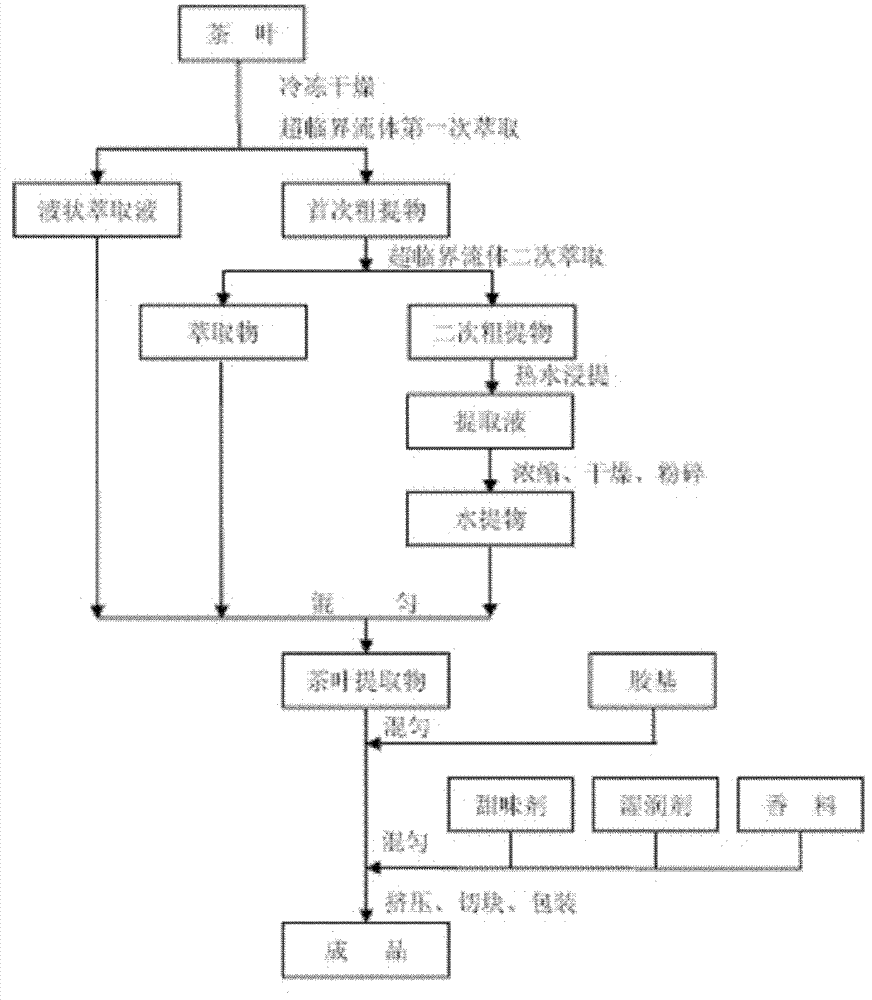

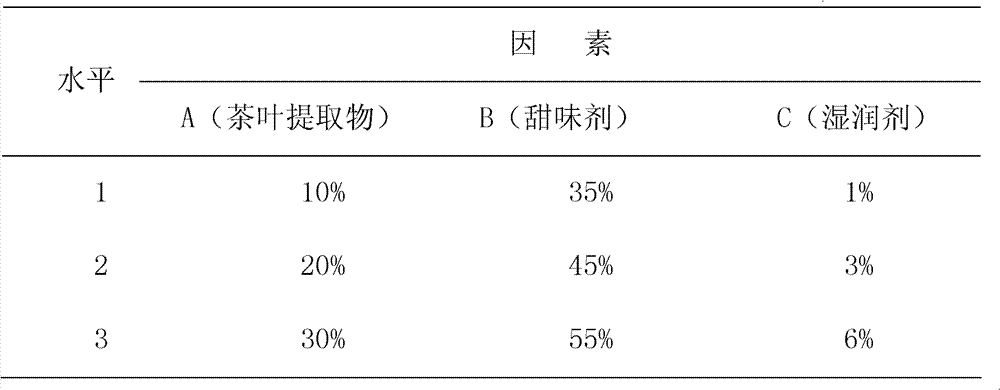

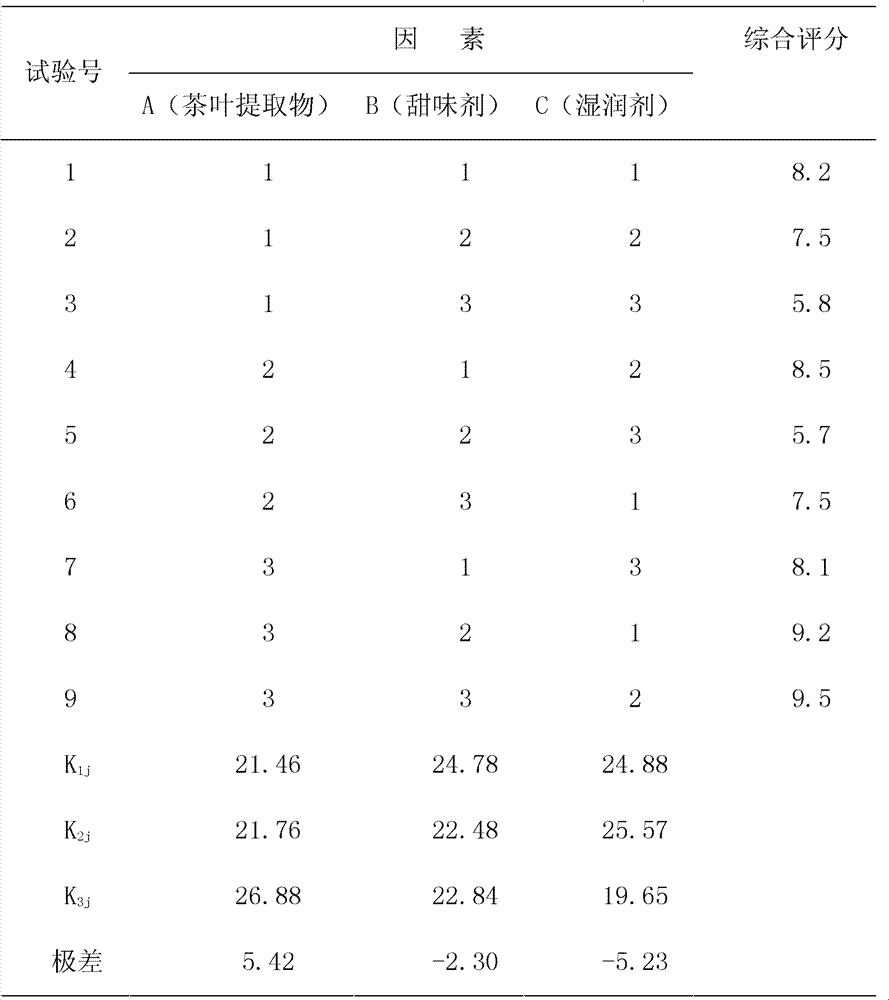

[0030] Such as figure 1 As shown, take 40kg of tea leaves, after drying, send them into a supercritical extraction kettle, extract the fluid with carbon dioxide, extract for 5 hours under the condition of maintaining the temperature at 30°C and the pressure at 25MPa, and perform the first separation to obtain 1.9kg of volatile oil and The first crude extract; the first crude extract continues to enter the separation tank for secondary separation, adding anhydrous ethanol entrainer, extracting at a temperature of 45°C and a pressure of 30MPa for 5 hours to obtain 2.3kg of the extract and the second crude extract; The sub-crude extract was leached in hot water at 80°C for 3 hours, the water extract was concentrated and dried, and then pulverized to obtain 1.7kg of water extract, and the above-mentioned volatile oil, extract and water extract were combined and mixed to obtain tea leaf extract Take 0.783kg of tea extract, stir and mix the tea extract and 0.822kg of gum base in a 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com