Composite metal electrolytic rod

A composite metal and electrolytic rod technology, applied in the electrolysis process, electrolysis components, electrodes, etc., can solve the problems of waste, increase the weight of electrodes, waste electricity resources, etc., and achieve the effect of reducing production costs, stable chemical properties, and increasing strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to make a clearer and clearer definition of the protection scope of the present invention.

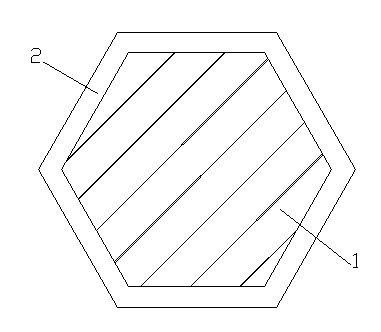

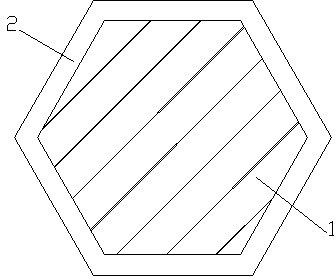

[0013] The present invention is a composite metal electrolytic rod, such as figure 1 Shown: The present invention is a composite metal electrolytic rod. The composite metal electrolytic rod includes a base 1 and a metal tube 2 on the surface of the base 1. The base 1 is made of silicone rubber with a small amount of copper-plated silver-plated conductive glue. In the conductive adhesive, silicone rubber accounts for 90%-96%, and copper-plated silver materials account for 4%-10%. The metal tube 2 on the surface is a copper tube, and the thickness of the copper tube is 1.5 mm-2.5 mm. The conductive glue 1 and the copper tube 2 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com