Production method of non-oriented silicon steel for agricultural motor

A technology of oriented silicon steel and production method, which is applied to furnace types, furnaces, heat treatment furnaces, etc., can solve the problems of increasing production costs and raw material costs, and achieve the effects of downgrading production costs and improving magnetic induction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

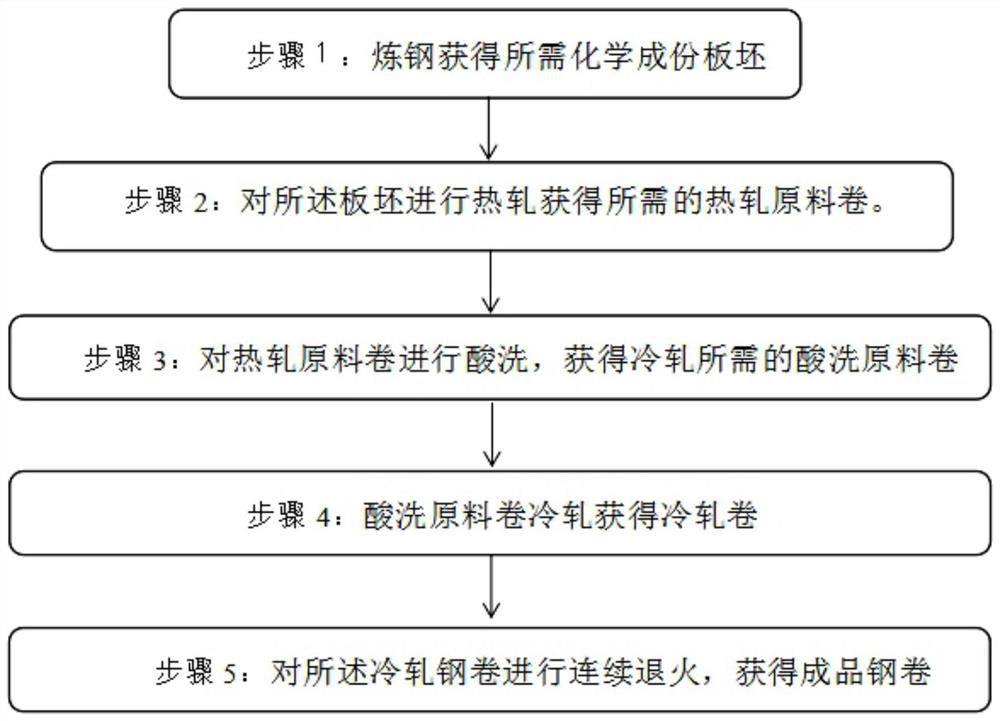

Method used

Image

Examples

Embodiment 1

[0043] 1. Steel components:

[0044] Among them, the mass percentages of C, Si, Mn, P, S, and ALs are: 0.032%, 0.40%, 0.25%, 0.013%, 0.004%, 0.028%, and the margin is FE and inevitable inclusions. Smelting chemical composition control, inclusions, and co-casting after molten chemical components;

[0045] 2, hot rolling; where the hot rolling heating temperature is 1050 ° C, hot rolling adopts high temperature final rolling and high temperature curling, the final rolling temperature is 860 ~ 890 ° C; the curl temperature is 680 to 720 ° C;

[0046] 3, pickling;

[0047] 4, cold rolling;

[0048] 5, continuous annealing; where the preheating section NOF temperature is 1000-1050 ° C, the RTF temperature of the radiation heating section is 900-930 ° C, and the heating section SF furnace temperature is annealed.

[0049] The finished product has a thickness of 0.5 mm.

Embodiment 2

[0063] 1. Steelmaking ingredients are:

[0064] Among them, the mass percentages of C, Si, Mn, P, S, and ALs are: 0.03%, 0.43%, 0.24%, 0.014%, 0.004%, 0.025%, and the margin is Fe and inevitable inclusions. Smelting chemical composition control, inclusions, and co-casting after molten chemical components;

[0065] 2, hot rolling; where the hot rolling heating temperature is 1050 ° C; hot rolling is high temperature rolling and high temperature curling, the final rolling temperature is 870 ° C; the curl temperature is 700 ° C;

[0066] 3, pickling;

[0067] 4, cold rolling;

[0068] 5, continuous annealing; where the preheating section NOF temperature is 1000-1050 ° C, the RTF temperature of the radiation heating section is 900-930 ° C, and the heating section SF furnace temperature is annealed.

[0069] The finished product has a thickness of 0.5 mm.

Embodiment 3

[0083] 1. Steelmaking ingredients are:

[0084] Among them, the mass percentages of C, Si, Mn, P, S, and ALs are: 0.03%, 0.43%, 0.24%, 0.014%, 0.004%, 0.025%, and the margin is Fe and inevitable inclusions. Smelting chemical composition control, inclusions, and co-casting after molten chemical components;

[0085] 2, hot rolling; where the hot rolling heating temperature is 1050 ° C; hot rolling adopts high temperature final rolling and high temperature curling, final rolling temperature 870 ° C; curl temperature is 700 ° C

[0086] 3, pickling;

[0087] 4, cold rolling;

[0088] 5, continuous annealing; where the preheating section NOF temperature is 1000-1050 ° C, the RTF temperature of the radiation heating section is 900-930 ° C, and the heating section SF furnace temperature is annealed.

[0089] The finished product has a thickness of 0.5 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com