Method and apparatus for preparing flocculant

A flocculant and equipment technology, applied in the field of preparing water treatment flocculants, can solve the problems of reducing electrode concentration polarization electrolysis electrode polarization and passivation, difficult process control conditions, long electrochemical reaction time, etc. Conductivity, improve electrolysis efficiency, weaken the effect of polarization phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

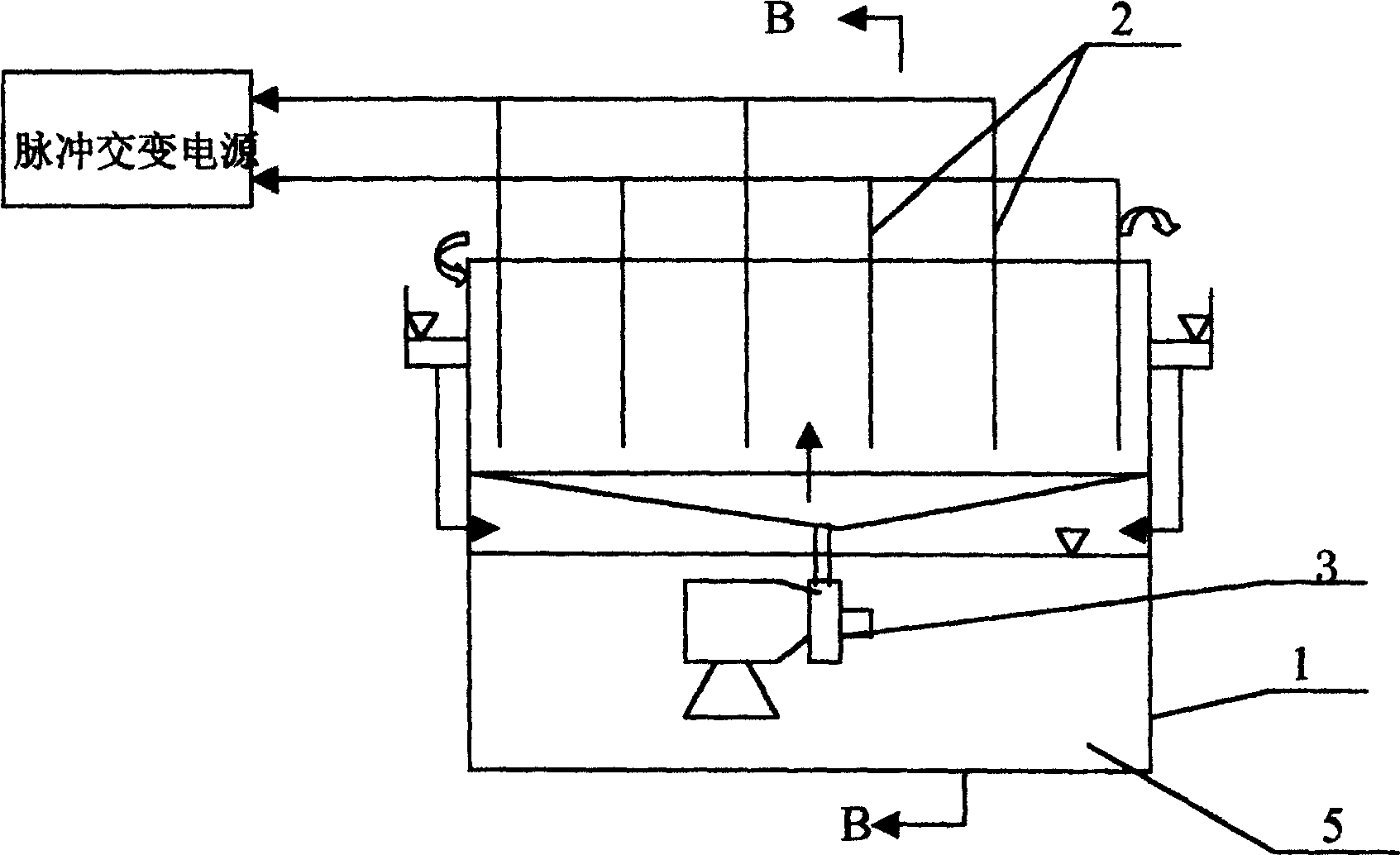

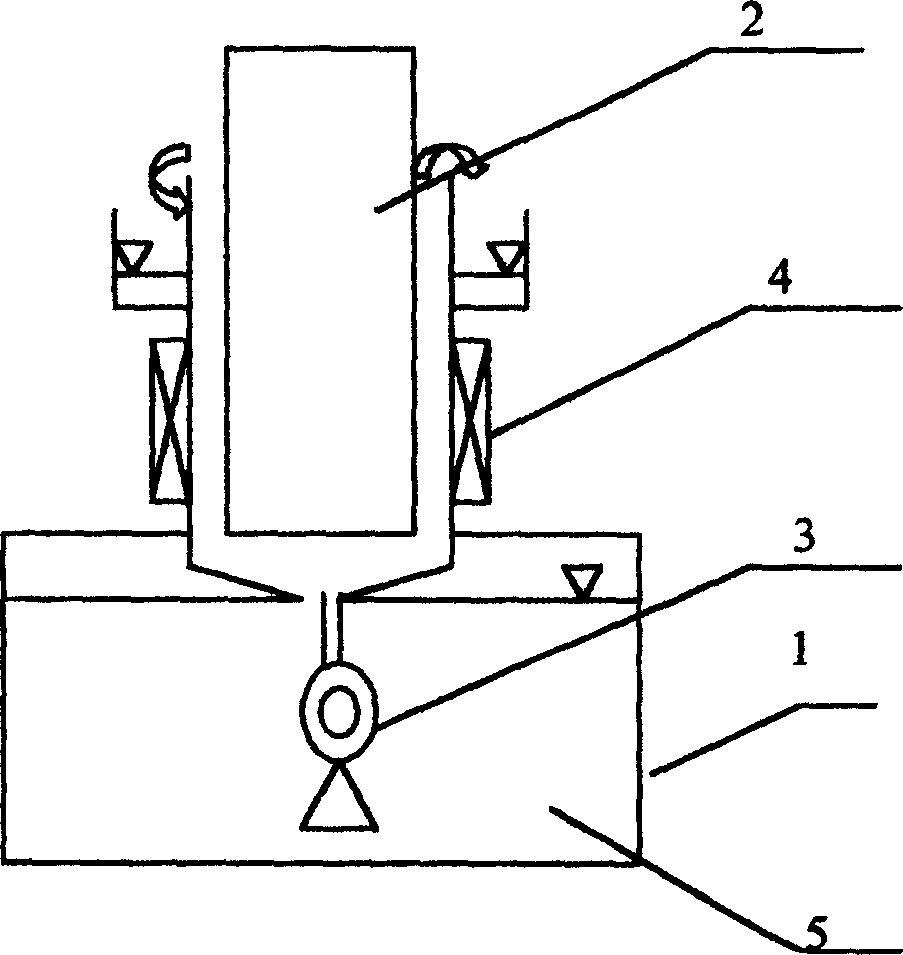

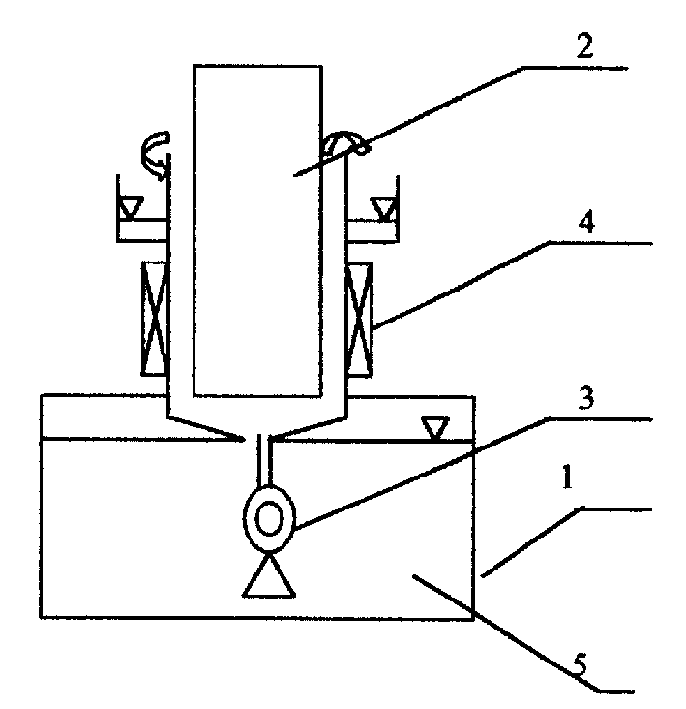

[0053] Such as figure 1 , figure 2 As shown, in a plexiglass electrolytic cell with a magnetic field (volume 60×20×150mm) with a volume of 1000ml 3 ) by adding 0.1mol / l AlCl 3 Aqueous solution 500ml, carry out electrolysis under the following conditions:

[0054] Electrode Anode Aluminum plate (aluminum processing corner waste) 15×150×15mm 3 pieces

[0055] Cathode aluminum plate (aluminum processing scrap) 15×150×15mm 3 pieces

[0056] Electrode spacing: 8mm

[0057] Electrolysis power supply: alternating pulse power supply

[0058] Circuit Connection: Parallel

[0059] Alternating pulse current frequency: 1HZ

[0060] Pulse duty time: 0 seconds

[0061] Instantaneous maximum value of pulse voltage: about 9V

[0062] Instantaneous maximum pulse current: 5A

[0063] Additional magnetic field: horizontal inhomogeneous magnetic field

[0064] Magnetic induction at the strongest additional magnetic field: 0.1T

[0065] Electrolyte temperature change: 20~60℃ ...

Embodiment 2

[0069] Such as figure 1 , figure 2 As shown, in a plexiglass electrolytic cell with a magnetic field (volume 60×20×150mm) with a volume of 1000ml 3 ) by adding 0.1mol / l AlCl 3 aqueous solution.

[0070] Electrode Anode Aluminum plate (aluminum processing corner waste) 15×150×15mm 3 pieces

[0071] Cathode aluminum plate (aluminum processing scrap) 15×150×15mm 3 pieces

[0072] Electrode spacing: 8mm

[0073] Electrolysis power supply: alternating pulse power supply

[0074] Circuit Connection: Parallel

[0075] Alternating pulse current frequency: 3Hz

[0076] Pulse duty time: 0 seconds

[0077] Instantaneous maximum value of pulse voltage: around 6V

[0078] Instantaneous maximum pulse current: 6A

[0079] Additional magnetic field:

[0080] Pulse frequency of vertical pulsating magnetic field: 25Hz

[0081] Instantaneous maximum magnetic induction: 0.2T

[0082] Electrolysis time: 90 minutes

[0083] Electrolyte temperature change: 20~60℃

[0084] After...

Embodiment 3

[0086] Such as figure 1 , figure 2 As shown, in a plexiglass electrolytic cell with a magnetic field (volume 60×20×150mm) with a volume of 1000ml 3 ) by adding 0.1mol / l of FeCl 3 aqueous solution.

[0087] Electrode Anode Iron plate (iron processing corner waste) 15×150×15mm 3 pieces

[0088] Cathode iron plate (iron processing scrap) 15×150×15mm 3 pieces

[0089] Electrode spacing: 8mm

[0090] Electrolysis power supply: alternating pulse power supply

[0091] Circuit Connection: Parallel

[0092] Alternating pulse current frequency: 3Hz

[0093] Pulse duty time: 0 seconds

[0094] Instantaneous maximum value of pulse voltage: around 6V

[0095] Instantaneous maximum pulse current: 6A

[0096] Additional magnetic field:

[0097] Pulse frequency of vertical pulsating magnetic field: 25Hz

[0098] Instantaneous maximum magnetic induction: 0.2T

[0099] Electrolysis time: 90 minutes

[0100] Electrolyte temperature change: 20~60℃

[0101] After the electrol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com