Steel reinforced concrete combined hollow floor and construction method thereof

A hollow floor, steel-concrete technology, used in floors, building components, buildings, etc., can solve problems such as poor anti-corrosion and fire resistance, poor concrete tensile capacity, and difficulty in pouring concrete, and achieves the ability to avoid fire and corrosion. The effect of good performance and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

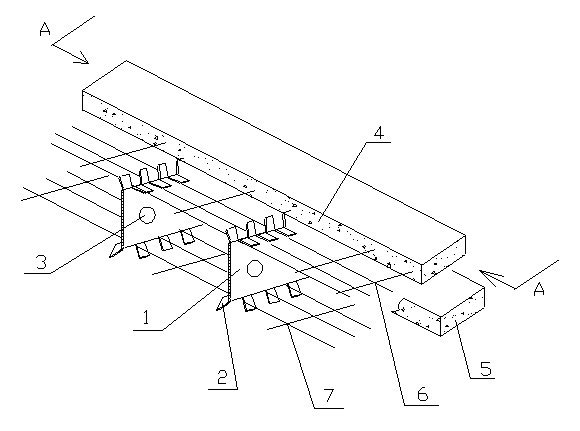

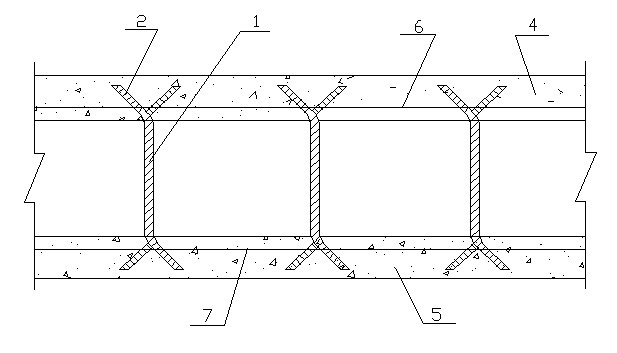

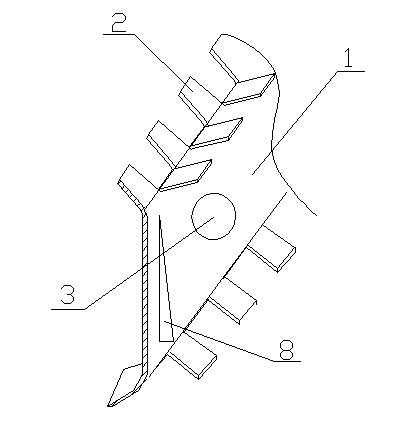

[0036] like figure 1 As shown in -3, the steel-concrete composite hollow floor includes multi-directional steel beams and upper and lower layers of post-cast reinforced concrete. There are several tooth wings 2 staggered to the left and right sides of the web 1; the web 1 is provided with lightening holes 3 and stiffeners 8; the tooth wings 2 on the upper and lower long sides of the web 1 are respectively embedded with The upper post-cast reinforced concrete 4 of the upper layer of steel bars 6, and the lower post-cast reinforced concrete 5 with the lower layer of reinforced bars 7.

[0037] In this embodiment, the cross section of the web 1 is rectangular; the steel beam is a cut I-shaped steel, the upper and lower long sides of the I-shaped steel are cut to form tooth wings, and the middle part of the I-shaped steel is a web. The tooth wings are one or more of rectangle, zigzag, arc, triangle, circle, ellipse or trapezoid.

[0038] The steel-concrete combined hollow floor ...

Embodiment 2

[0049] like Figure 4 As shown, the steel-concrete composite hollow floor, the steel beam includes a web 1 whose cross section is a circular arc segment curve, and the tooth wing 2 is a web cut formed by shearing the upper and lower edges of the web 1; the rest is the same as in Example 1 .

Embodiment 3

[0051] like Figure 5 As shown, the steel-concrete composite hollow floor, the steel beam includes a rectangular web 1 whose cross section is composed of "П" line segments, and the tooth wings 2 are connected by bolts or welded to the upper and lower ends of the web 1; the rest are the same as in Example 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com