Ignition electrode suitable for multiple radiant tube burners

An ignition electrode and electrode technology, applied in the direction of ignition by electric spark, combustion ignition, combustion method, etc., can solve the problems of easy loss of electrodes, unstable flame monitoring, etc., to prolong service life, reduce temperature, and enhance reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with implementation examples and accompanying drawings, but the present invention is not limited.

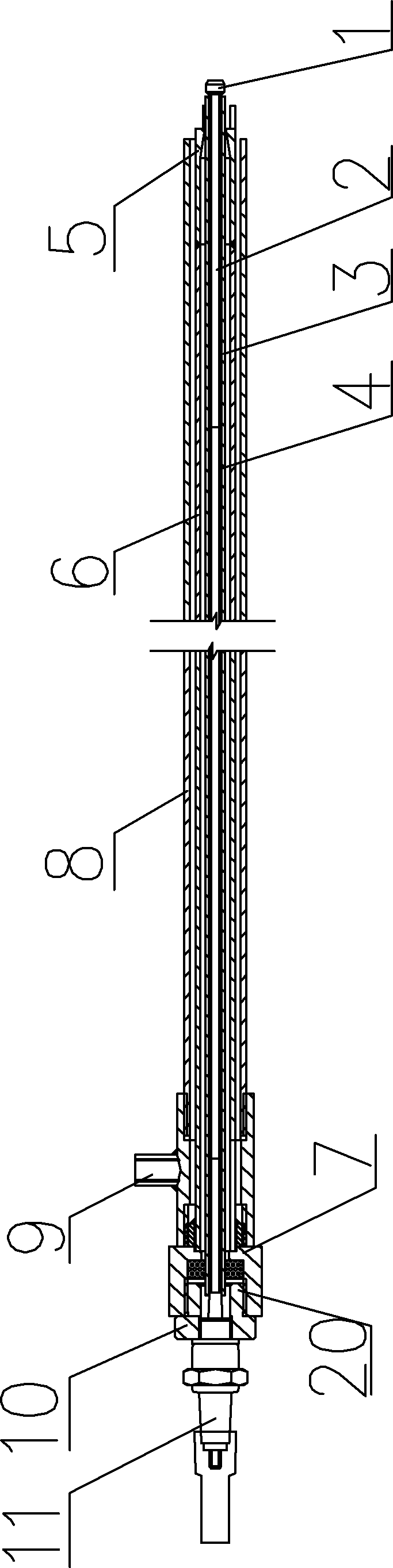

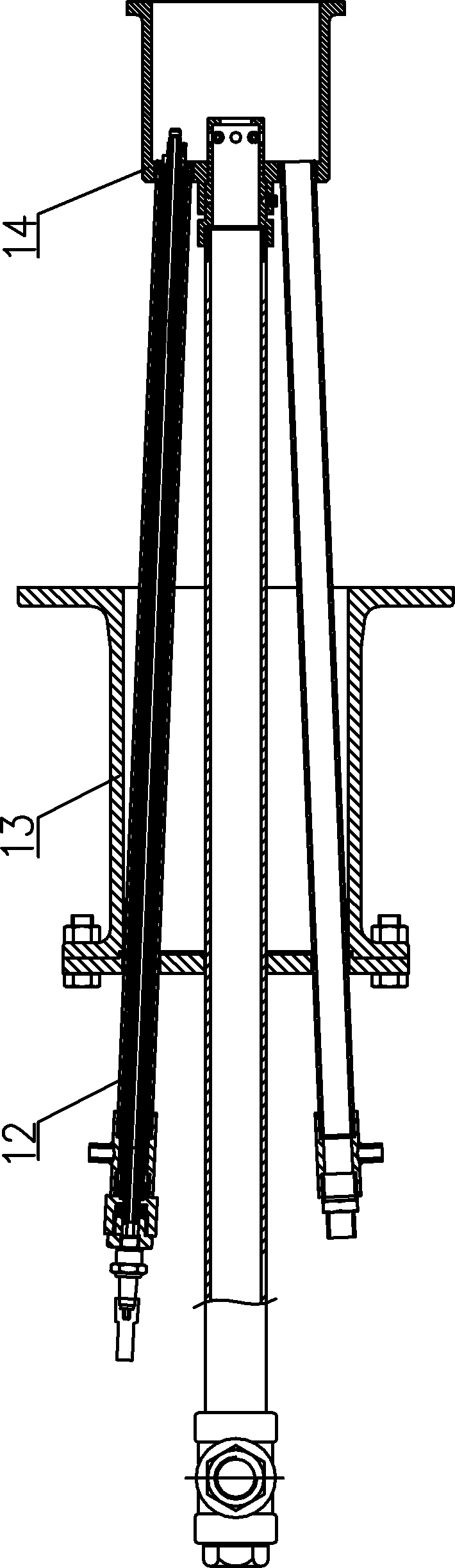

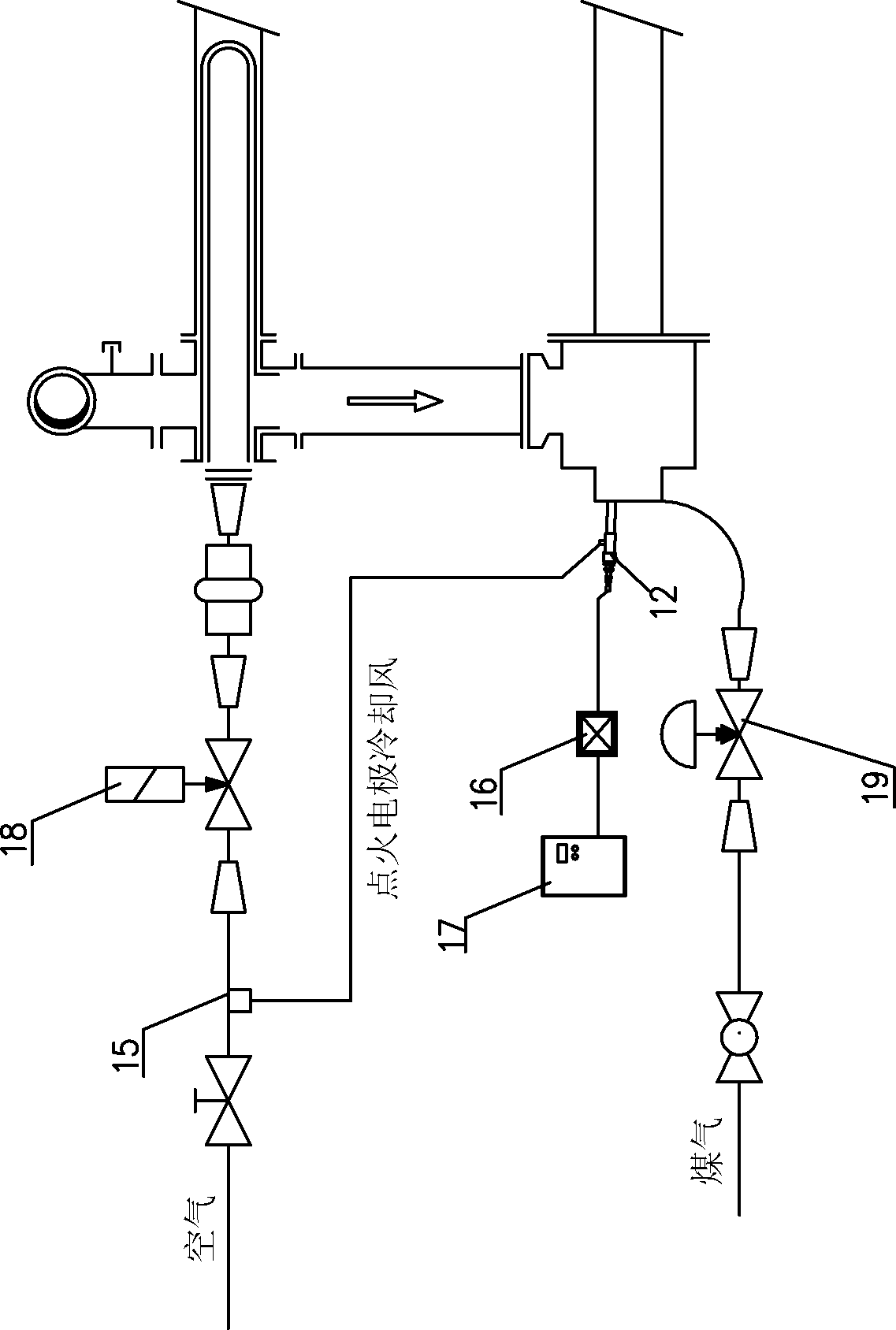

[0025] figure 1 Shown is an ignition electrode implemented according to the present invention, including a ignition head 1, an electrode wire 2, an insulating ceramic tube 3, a toothed iron 4, an ignition triangle bracket 5, an electrode tube 6, a connector 7, an electrode guide 8, and a cooling air Sleeve 9, electrode mounting joint 10, electrode head 11, gasket 20; ignition head 1 is cut and formed by HN (25Ni-20Cr) heat-resistant steel wire, both ends are double-prism columnar structure, and the center is opened with electrode wire 2 A circular hole with matching diameter is squeezed and fixed with the electrode wire. The electrode wire 2 is made by straightening the heat-resistant alloy resistance wire, and the electrode wire 2 is made in sections, and each section is fixed by clamping iron 4. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com