Convection/radiation integrated heat exchange terminal

A technology of heat exchanger and terminal equipment, applied in the field of terminal equipment of chiller air-conditioning units, can solve the problems of easy condensation, insufficient cooling capacity, huge initial investment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The content of the present invention will be described in detail below in conjunction with the drawings and specific embodiments. It should be understood that the present invention is not limited to the following preferred embodiments, which are only used as illustrations of the present invention.

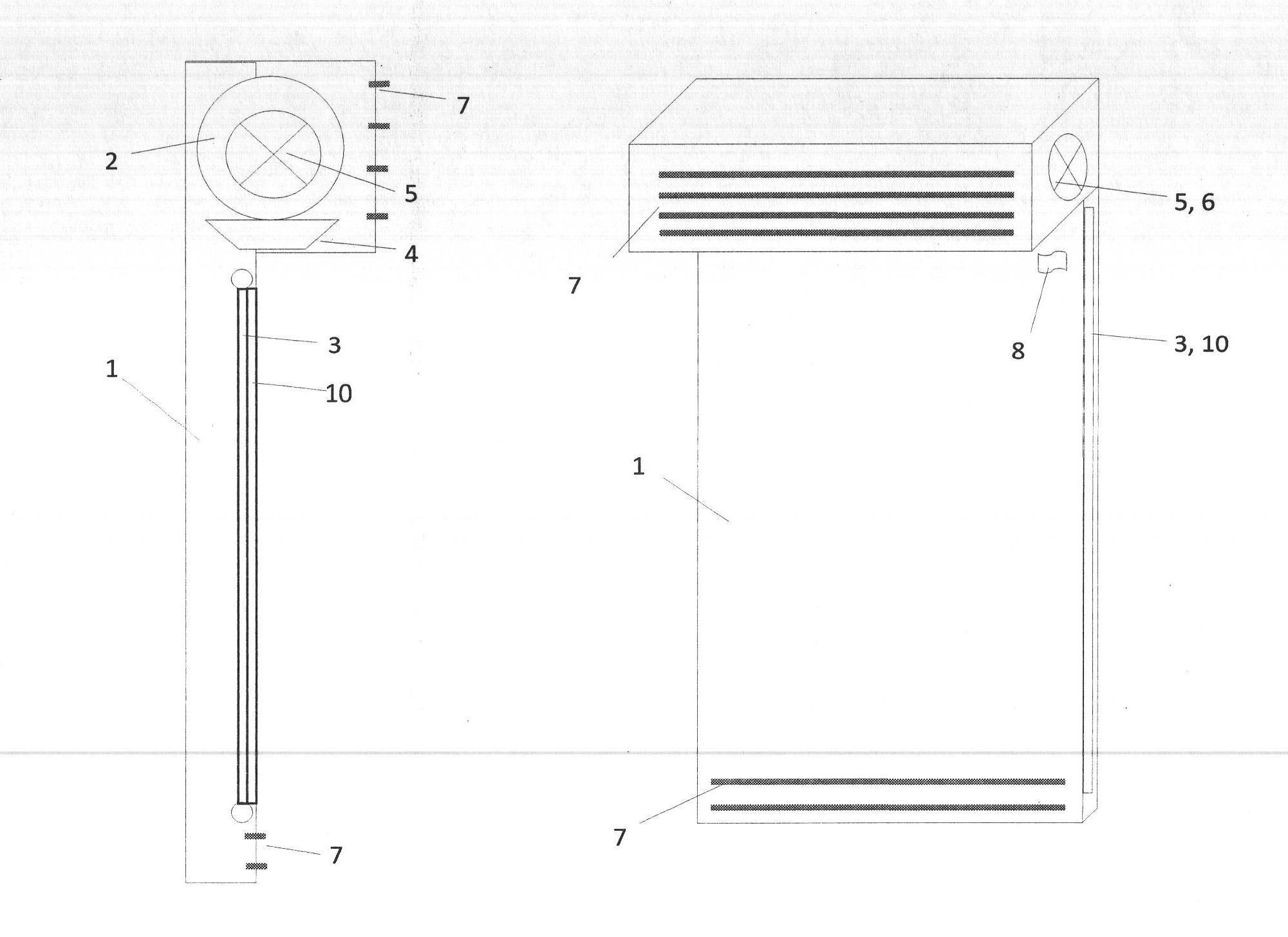

[0022] Such as figure 1. As shown, the present invention is mainly composed of a casing 1 , a first heat exchanger 2 , a second heat exchanger 3 , a condensation pan 4 , a dew point detector 8 and an electric tee 9 . The upper end inside the housing is the first heat exchanger, with a built-in fan 5 to enhance convection, round holes at both ends of the housing are air inlets 6, and louver air outlets 7 are opened on the protruding surface of the upper part of the housing.

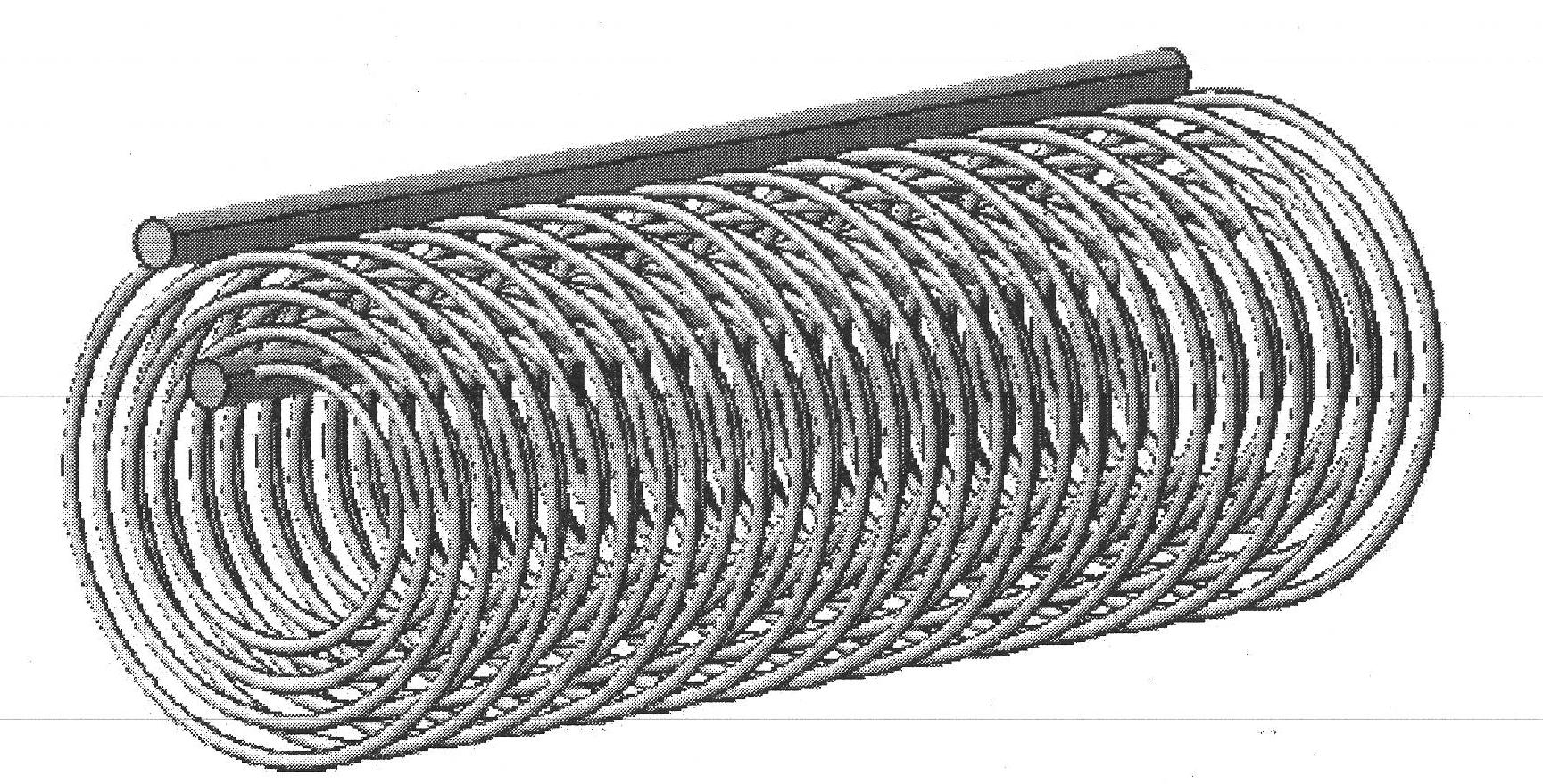

[0023] Such as figure 2. As shown, the first heat exchanger 2 of the present invention, namely the convective heat exchanger, is a coiled capillary heat exchanger.

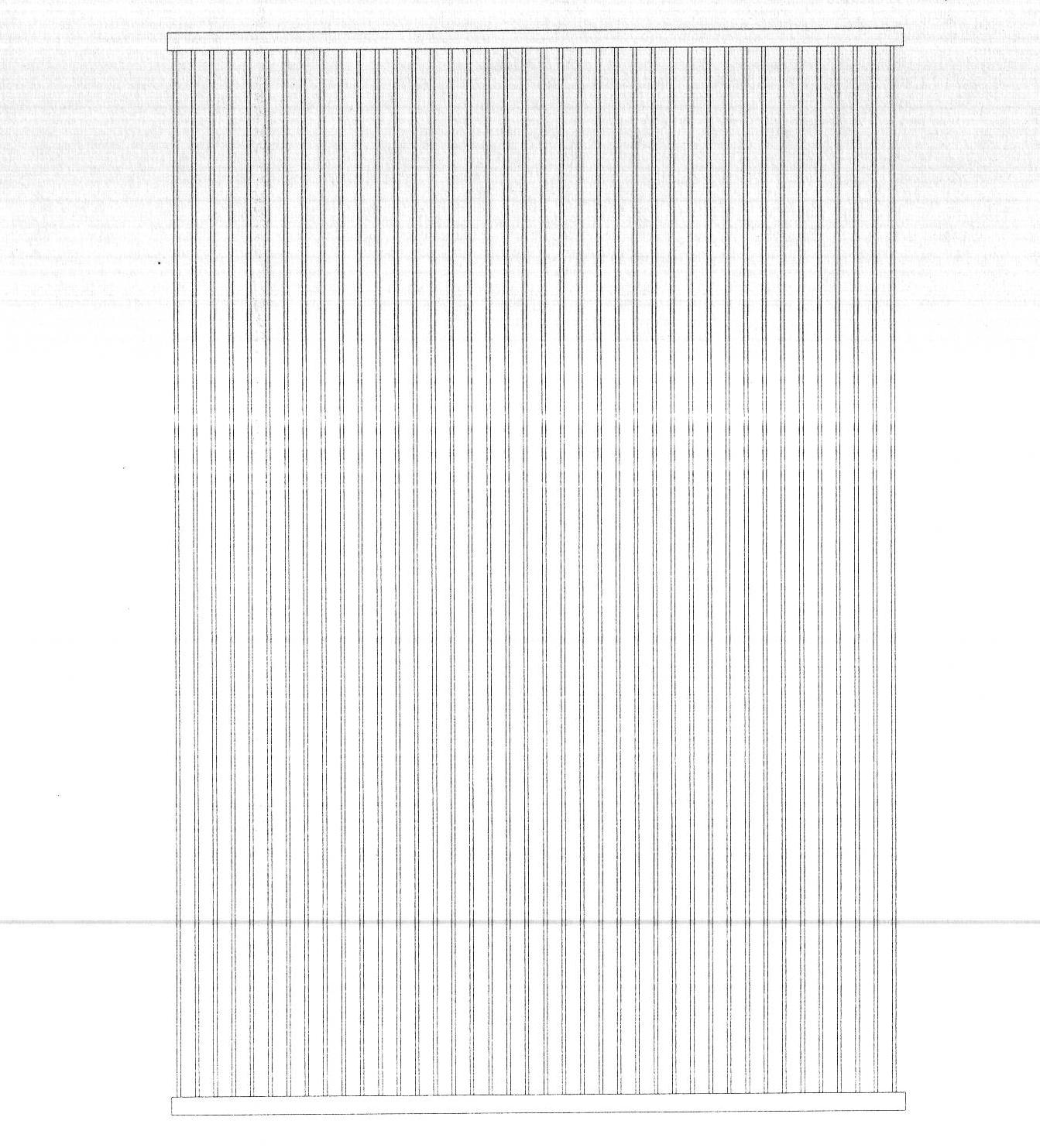

[0024] Such as image 3. As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com