Method for laying lining side support block row of rotary kiln

A technology of rotary kiln and block, applied in the direction of rotary drum furnace, lining repair, furnace, etc., to ensure the service life, save the time of installation and removal of support, and improve the effect of horizontal transportation environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

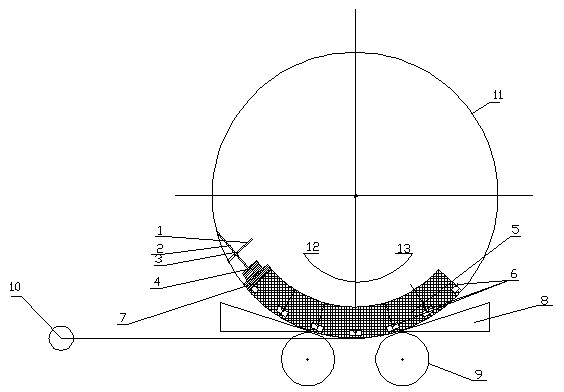

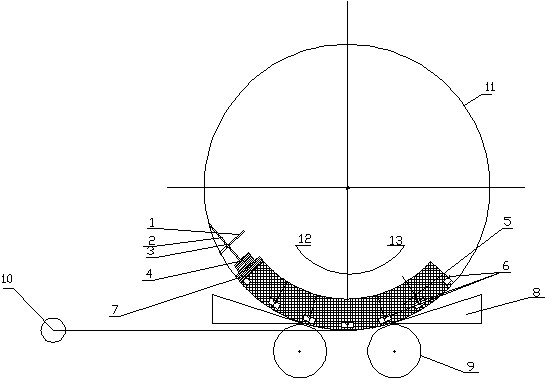

[0018] For further describing the present invention, below in conjunction with figure 1 A method for building a row of supporting blocks for the lining of a rotary kiln according to the present invention will be further described with examples.

[0019] The first step is to pop up the welding reference line.

[0020] Insert the wooden wedge (8) between the supporting surface of the rotary kiln (11) kiln body and the kiln body roller (9) to fix the rotary kiln (11) kiln body. A welding datum line parallel to the center line is elastically set on the inner wall of the kiln shell of the rotary kiln (11).

[0021] The second step is to build the first set of blocks.

[0022] Weld the anchors (6) of the first group of blocks in the first column along the welding reference line, and weld one anchor (6) between two adjacent blocks in the same ring. Build the first row of blocks (5) in the counterclockwise direction (13), and tap the anchors of the first row and the grooves of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com