Method for adjusting camber and/or toe

A technology for adjusting wheels and wheel bases, applied in transportation and packaging, cantilevers mounted on pivots, interconnection systems, etc., which can solve problems such as the inability to realize the transmission ratio, and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

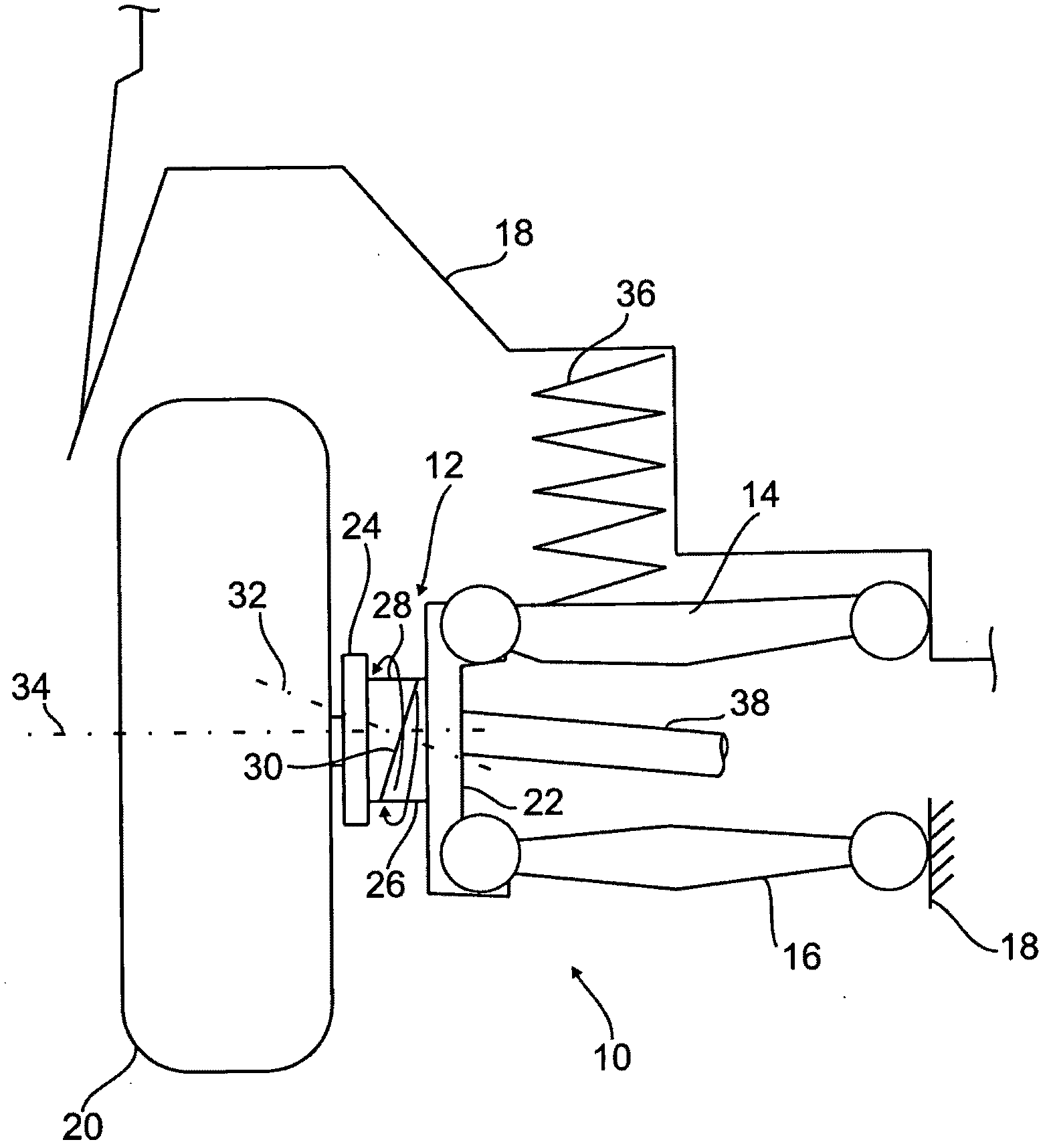

[0019] figure 1 A rough schematic diagram shows a wheel suspension arrangement 10 for a motor vehicle, in which a wheel carrier 12 is articulated to the only indicated bodywork via transverse control arms 14 , 16 as wheel guide elements. 18 on.

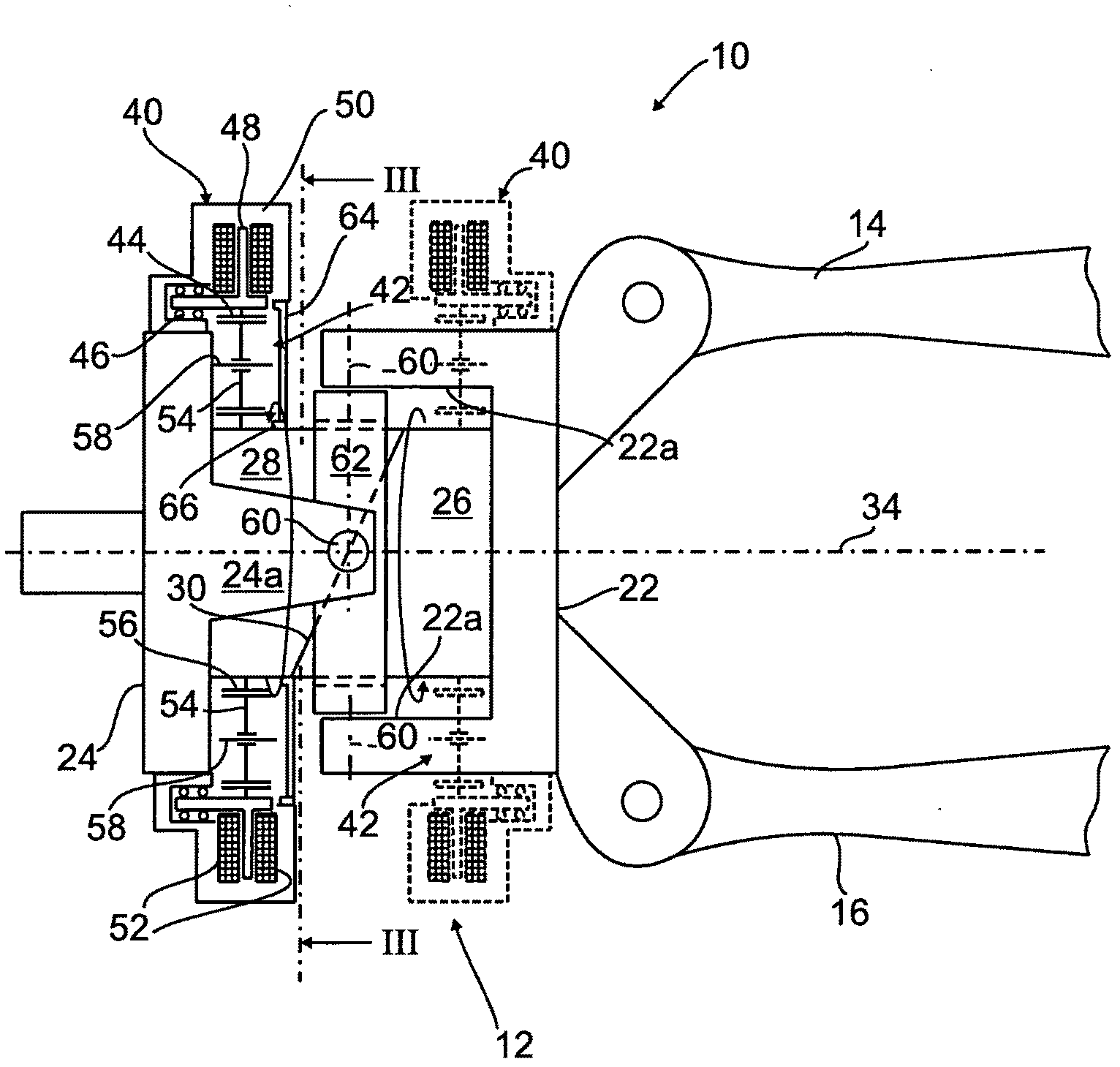

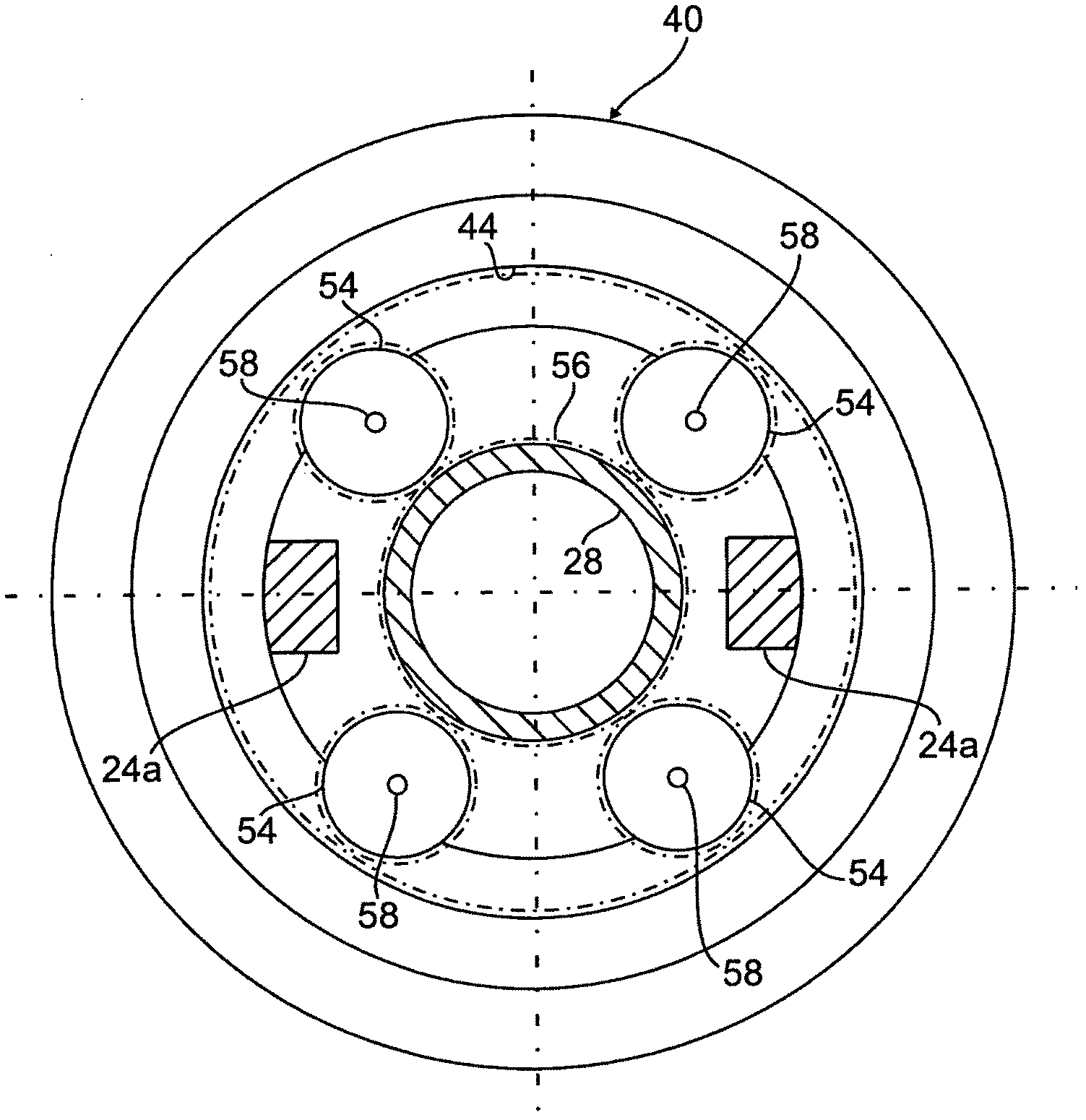

[0020] The wheel hub bracket 12 that receives the wheel 20 in a rotatable manner is divided into a guide 22 hinged on the lateral control arms 14, 16, a carrier 24 that receives the wheel 20 through a corresponding wheel support (not shown) and Two adjusting cylinders 26 , 28 are rotatably supported on the guide part 22 and on the carrier part 24 and can be adjusted on an axis of rotation 32 extending perpendicularly to the inclined surfaces 30 facing each other. . Rotation of one or both adjusting cylinders 26 , 28 pivots carrier part 24 relative to wheel axis of rotation 34 , and correspondingly adjusts the track and / or camber of wheel 20 of wheel suspension arrangement 10 .

[0021] Wheel loads are supported relative to the body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com