Processing method for freeze-drying garlic slices by vacuum microwaves

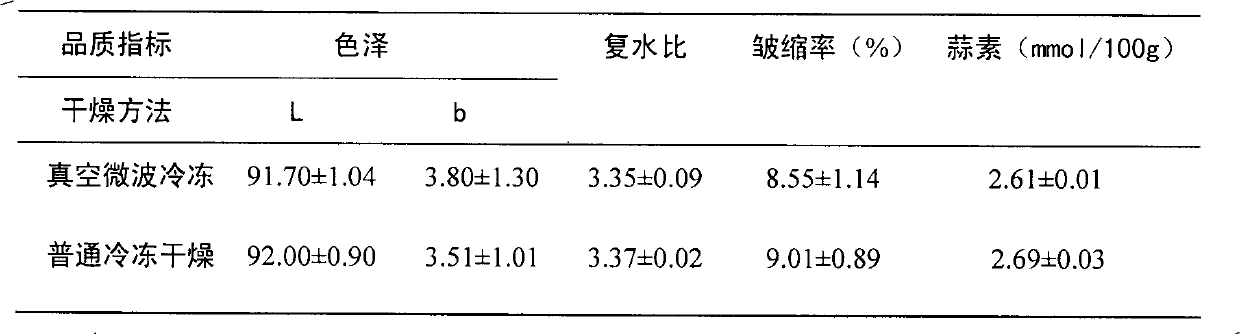

A vacuum microwave and processing method technology, applied in food preservation, fruit and vegetable preservation, food science, etc., can solve the problems of high energy consumption, long time consumption, and restrictions on the industrial production of freeze-drying technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

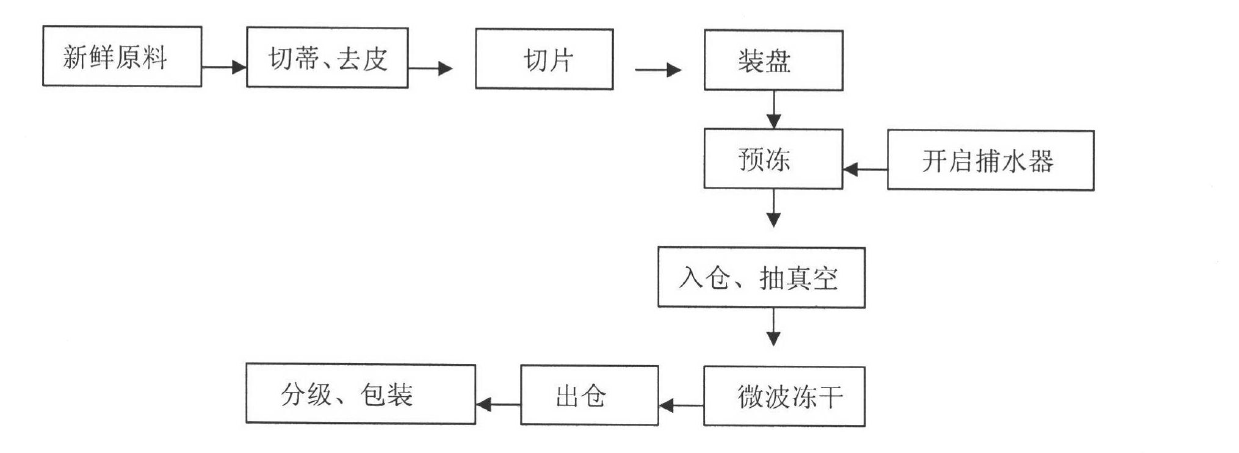

Method used

Image

Examples

Embodiment 1

[0026] (1) Material pretreatment: Pour the garlic on the garlic selection table, remove the moth-eaten and mildewed garlic, then use a cutting machine to cut the garlic cloves, pour the cut garlic cloves on the elevator, and send them to the sorting machine through the conveyor belt. The flap machine performs splitting. After the split garlic is dried off-line, the outer coat and transparent film of the garlic cloves are removed, and the unremoved garlic skins are manually picked out. Finally, cut into 2mm garlic slices with a multi-functional slicer.

[0027] (2) Pre-freezing: Spread 10Kg of material in the tray, 1Kg per tray, spread less material in the middle and more around the periphery. Lower the storage temperature of the freezer to -10°C in advance, and place the material in the freezer for 30 minutes. Then lower the storage temperature to -25°C to lower the material temperature to the eutectic point and keep it for 120 minutes.

[0028] (3) Warehousing and plate pl...

Embodiment 2

[0032] (1) Material pretreatment: Pour the garlic on the garlic selection table, remove the moth-eaten and mildewed garlic, then use a cutting machine to cut the garlic cloves, pour the cut garlic cloves on the elevator, and send them to the sorting machine through the conveyor belt. The flap machine performs splitting. After the split garlic is dried off-line, the outer coat and transparent film of the garlic cloves are removed, and the unremoved garlic skins are manually picked out. Finally, cut into 2mm garlic slices with a multi-functional slicer.

[0033] (2) Pre-freezing: spread 20Kg of materials in the material tray, 1Kg per tray, less material in the middle and more around the periphery. Lower the storage temperature of the freezer to -10°C in advance, and place the material in the freezer for 30 minutes. Then lower the storage temperature to -30°C to lower the material temperature to the eutectic point and keep it for 120 minutes.

[0034] (3) Warehousing and plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com