Preparation method of high-dispersibility white carbon black

A high-dispersion, white carbon black technology, applied in the field of white carbon black, can solve the problems that the production of white carbon black has not been reported, and achieve the effects of low production cost, no three waste emissions, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention can be further understood through the examples of the present invention given below, but the protection of the present invention is not limited thereto.

[0022] 1. Raw material selection

[0023] Since the mineral composition of kaolin tailings is mainly quartz, feldspar, feldspar and a certain amount of kaolin, the chemical composition is mainly SiO2 (its content is more than 90%) and Al2O3. Therefore, the use of kaolin tailings to prepare white carbon black mainly solves the separation problem of aluminum-containing minerals and quartz in filter residues. Generally, ordinary washed soil can be used. On this basis, kaolin with high aluminum content, high whiteness and low impurities is selected as raw material.

[0024] 2. Preparation method:

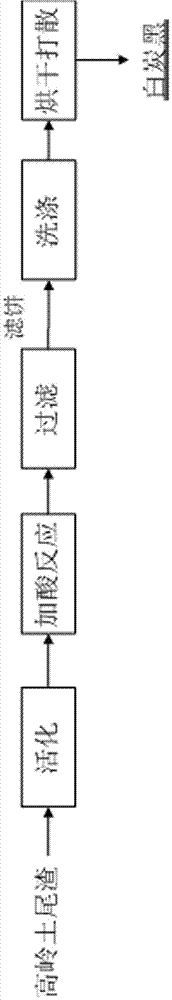

[0025] First, add a modifier to the kaolin tailings to activate, add water to adjust a certain proportion of slurry, then add sulfuric acid to the reaction kettle and use acidolysis heat to react; the ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com