Automatic cleaner for rubber frame of fermented bean curd

An automatic cleaning and latex technology, applied in the direction of cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of operator health, semi-finished product sanitation, workshop environment, low efficiency of manual cleaning of plastic frames, and inability to adapt to large quantities. Production requirements and other issues, to achieve the effect of simple structure, labor saving, and reducing drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in detail below in conjunction with accompanying drawing:

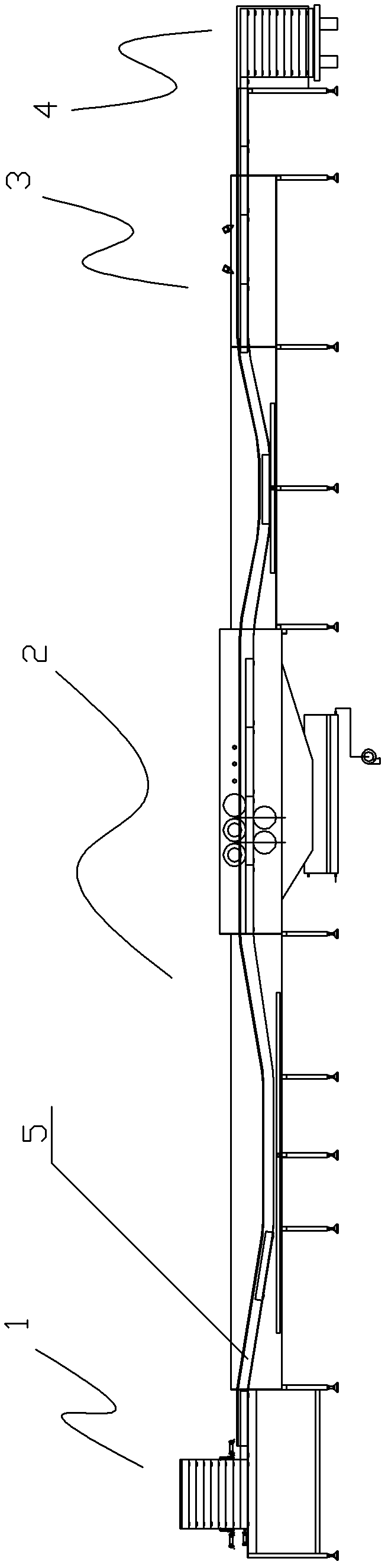

[0033] like figure 1 As shown, an automatic cleaning device for fermented bean curd rubber frame includes a feeding device 1, which is connected with a cleaning mechanism 2 and a drying system 3 in sequence, the feeding device 1, the cleaning mechanism 2 and the drying system 3 are connected by a conveying channel 5 connected. An automatic frame stacking system 4 is also connected to the drying system 3 .

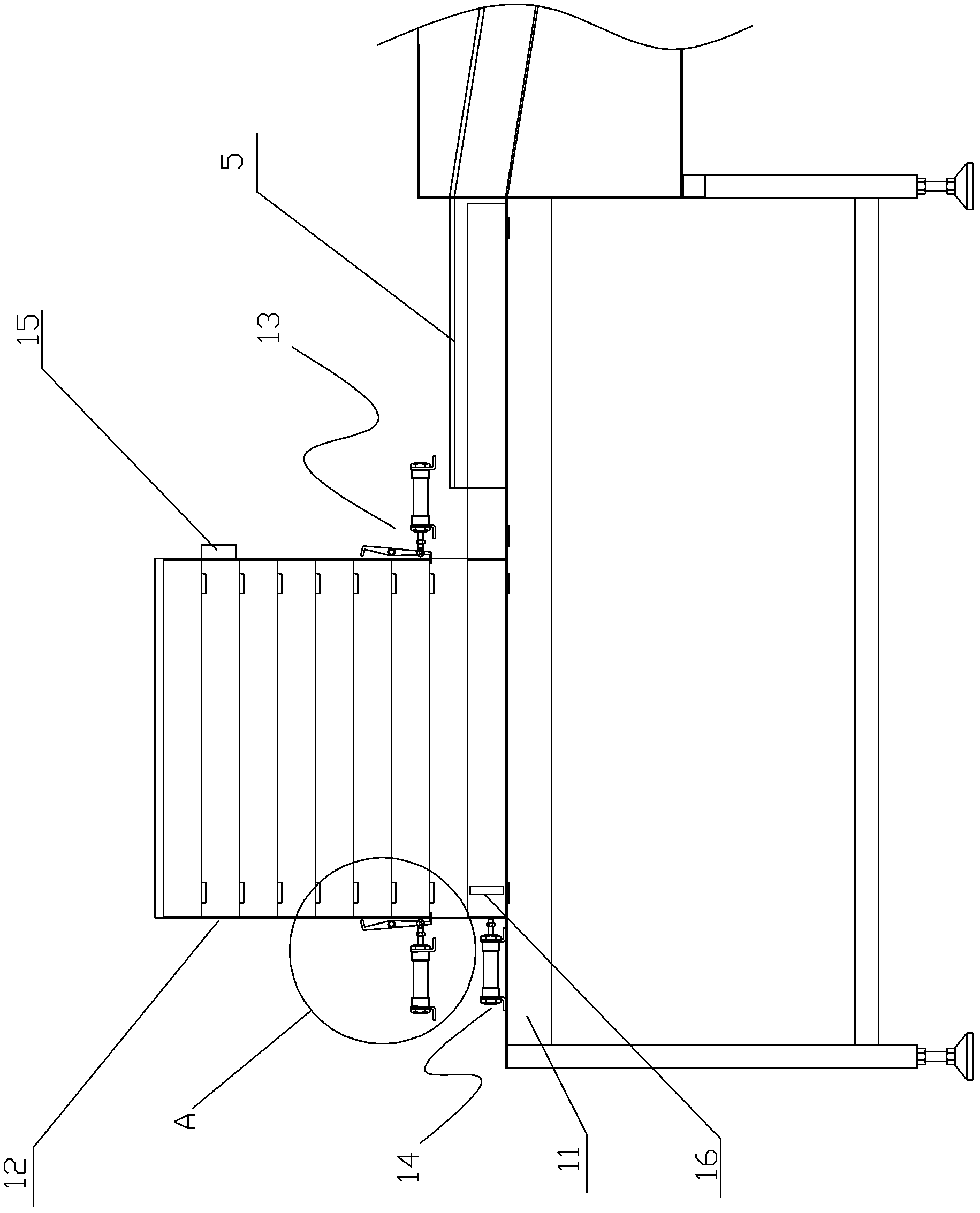

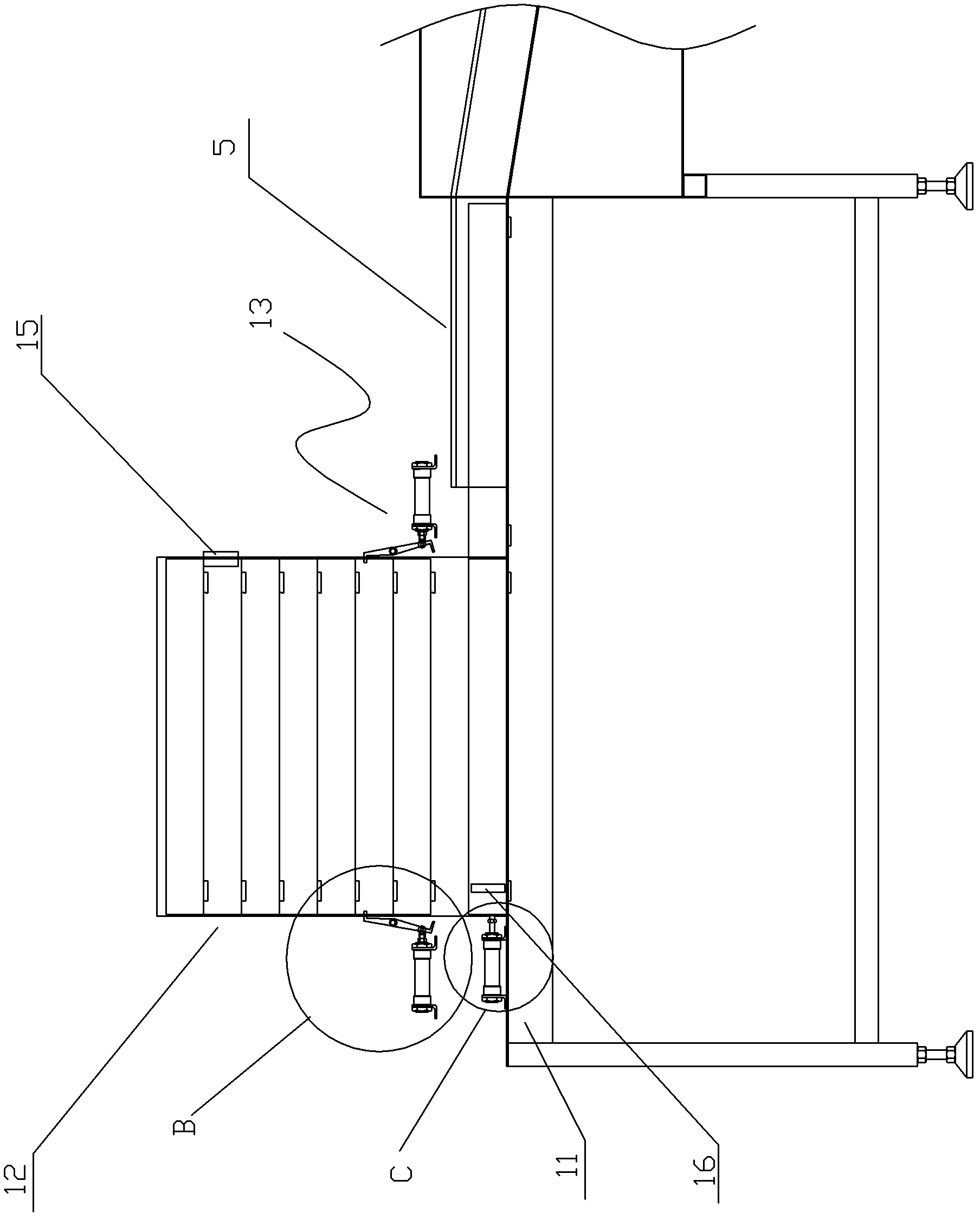

[0034] like Figure 2-6 As shown, the feeding device 1 includes a workbench 11, the workbench 11 is provided with a plastic frame positioning bar 12, and the plastic frame positioning bar 12 is provided with a control mechanism 13 for positioning and putting in the plastic frame. The bottom of 12 is provided with a pushing mechanism 14 that pushes the rubber frame into the cleaning mechanism 2.

[0035] The control mechanism 13 includes a fixed shaft 131, the fixed shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com