Programmable numerically-controlled machining lathe with automatic blanking auxiliary machine

A technology of CNC lathes and material auxiliary machines, applied in the field of lathes, can solve problems such as flying far away, troublesome work, unsafety, etc., and achieve the effects of simple overall structure, improved processing efficiency, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

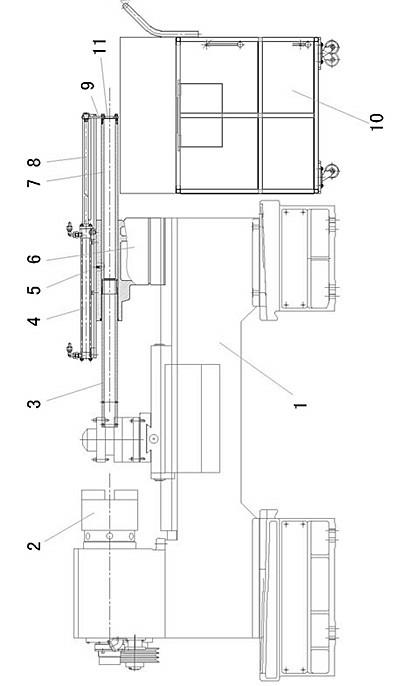

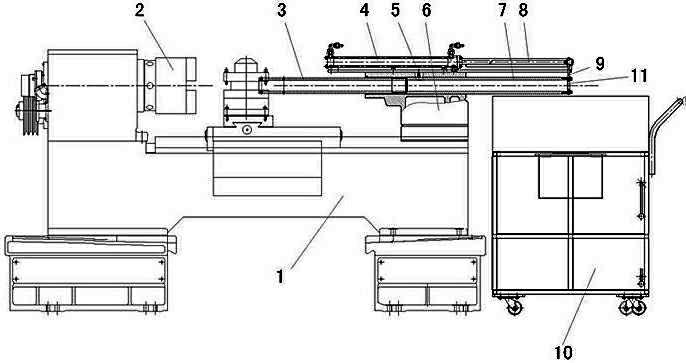

[0008] Such as figure 1 As shown: 1 is the bed of a programmable CNC lathe, a chuck 2 is installed on the upper left of the bed 1 through the headstock, and a tailstock 6 is arranged on the guide rail above the bed 1, between the tailstock 6 and the guide rail The structure is the same as the prior art. A tubular mandrel 7 is arranged in the tailstock 6, the right end of the tubular mandrel 7 stretches out to the rear side of the tailstock 6, and the center line of the tubular mandrel 7 is parallel to the guide rail longitudinally on the bed 1 top. A material receiving pipe 3 is connected to the left end of the tubular mandrel 7 through a threaded connection, and the left end of the material receiving pipe 3 stretches out to the front side of the tailstock 6 . The top of the tailstock 6 is fixedly connected with the oil cylinder 4 connected with the hydraulic control device, and the outer end of the piston rod 8 matched with the oil cylinder 4 is connected with the right end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com