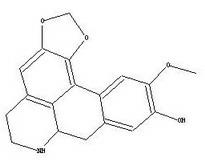

Method for extracting actinodaphnine from actinodaphne obovata

A technology of carnitine and carnitine, which is applied in the preparation field of extracting carnitine from plants, to achieve the effects of less pollution, favorable large-scale production operations, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Get 10Kg of the bark of Phoebe Phoebe Phoebe, crush it, and add it to CO 2 In the supercritical extractor, ethyl acetate is used as the entrainer, the entrainer accounts for 1% by volume of the total extraction solvent, the extraction pressure is 10MPa, the temperature is 40°C, CO 2 The flow rate is 1ml / g crude drug·min, the extraction time is 120min, and the extract is obtained, dissolved in ethanol, filtered, and the filtrate is taken, adsorbed by a 001×7 strong acidic styrene-type cation exchange resin column, and hydrochloric acid with a concentration of 1mol / L Solution elution, collect the eluent, pass through a 201×7 strong basic styrene-type anion exchange resin column, collect the effluent, concentrate, add to the D102 macroporous adsorption resin column, elute with 40% ethanol, collect 3 Double the column volume eluate, recover ethanol under reduced pressure and concentrate, add absolute ethanol to crystallize, separate and crystallize, wash and dry to obtain 0...

Embodiment 2

[0026] Get 10Kg of the bark of Phoebe Phoebe Phoebe, crush it, and add it to CO 2 In the supercritical extractor, ethyl acetate is used as the entrainer, the entrainer accounts for 3% by volume of the total extraction solvent, the extraction pressure is 30MPa, the temperature is 50°C, CO 2 The flow rate is 3ml / g crude drug·min, the extraction time is 140min, and the extract is obtained, dissolved in ethanol, filtered, and the filtrate is taken, adsorbed by a 001×4 strong acidic styrene-type cation exchange resin column, and hydrochloric acid with a concentration of 1mol / L Solution elution, collect eluate, pass through 201×4 type strong basic styrene type anion exchange resin column, collect effluent, concentrate, add to D102 macroporous adsorption resin column, elute with 40% ethanol, collect 8 times the column volume eluate, recover ethanol under reduced pressure and concentrate, add absolute ethanol to crystallize, separate and crystallize, wash and dry to obtain 0.67g of ca...

Embodiment 3

[0028] Get 10Kg of the bark of Phoebe Phoebe Phoebe, crush it, and add it to CO 2 In the supercritical extractor, ethyl acetate is used as an entrainer, the entrainer accounts for 2% by volume of the total extraction solvent, the extraction pressure is 20MPa, the temperature is 45°C, CO 2 The flow rate is 2ml / g crude drug·min, the extraction time is 130min, and the extract is obtained, dissolved in ethanol, filtered, and the filtrate is taken, adsorbed by a D001 strong acidic styrene-type cation exchange resin column, and washed with a hydrochloric acid solution with a concentration of 1mol / L. Remove, collect the eluate, pass through the D201 type strong basic styrene type anion exchange resin column, collect the effluent, concentrate, add to the D102 type macroporous adsorption resin column, elute with 40% ethanol, collect 5 times the volume of the column The eluate was recovered from ethanol under reduced pressure and concentrated, added absolute ethanol to crystallize, sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com