Method for separating and purifying fructooligosaccharides

A technology for separation and purification of fructooligosaccharides, applied in oligosaccharides, chemical instruments and methods, and methods based on microorganisms, can solve the problem of high cost of fructosyltransferase and achieve the effect of high product content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Example 1: Preparation of fructooligosaccharide fermentation broth

[0059] Phaffia strain JMU-MVP14 with high astaxanthin production was selected and bred. The volumetric yield of astaxanthin fermented by this strain reached 150 mg / L, and the cell yield of astaxanthin reached 6 mg / g. The fructo-oligosaccharide fermented liquid obtained by the fermentation of sucrose by Phaffia yeast JMU-MVP14, the specific preparation method is as follows:

[0060] Inoculate 1 ml of activated Phaffia yeast JMU-MVP14 into shaker flask culture medium, and culture at 22°C, 190 r / min for 72 h to obtain seed liquid; In a 7 L fermentation tank with L fermentation medium, the temperature was controlled at 22°C, the ventilation rate was 3 L / min, and the dissolved oxygen was controlled at 30-40% by adjusting the stirring speed; 25% ammonia water was automatically fed to control the pH 6.0; every 8 Take a sample once to measure the astaxanthin content. After the astaxanthin synthesis reaches ...

Embodiment 2

[0064] The filtrate containing fructooligosaccharides was obtained according to the method in Example 1. Ion exchange resin was used as an adsorption medium to separate fructo-oligosaccharides.

[0065] Put the pretreated ion exchange resin (SP-Sepharose resin) into the chromatographic column with a column volume of 40 ml. After the resin settles, keep the column temperature at 25°C and equilibrate with ultrapure water for 5 column volumes. According to the method in Example 1, the filtrate containing fructooligosaccharides was loaded on the chromatographic column with a flow rate of 1 ml / min, and the loading volume was 40 ml, and then washed with ultrapure water, and the flow rate was 1 ml / min. min, collect one tube per 5 ml, detect with HPLC, collect the collection solution containing fructooligosaccharides, load the sample on the Q-Sepharose column chromatography with ultrapure water to balance 5 column volumes, wash with ultrapure water, The flow rate is 1 ml / min, one tub...

Embodiment 3

[0067] The filtrate containing fructooligosaccharides was obtained according to the method in Example 1.

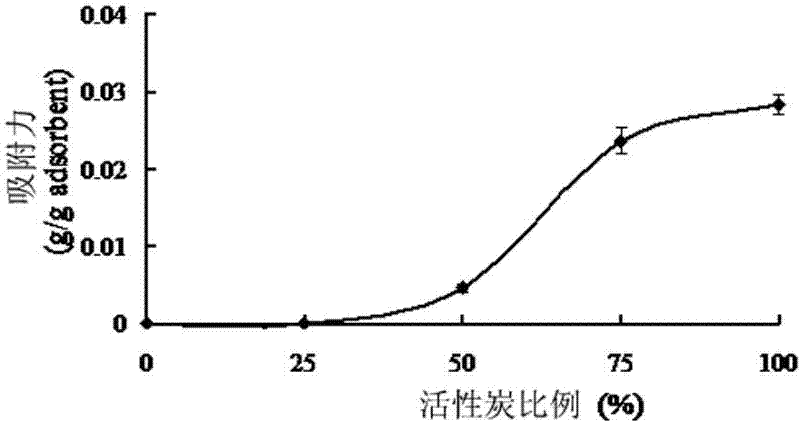

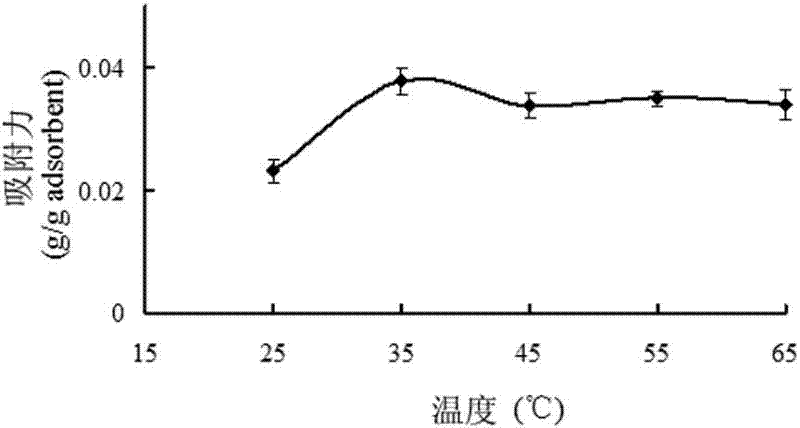

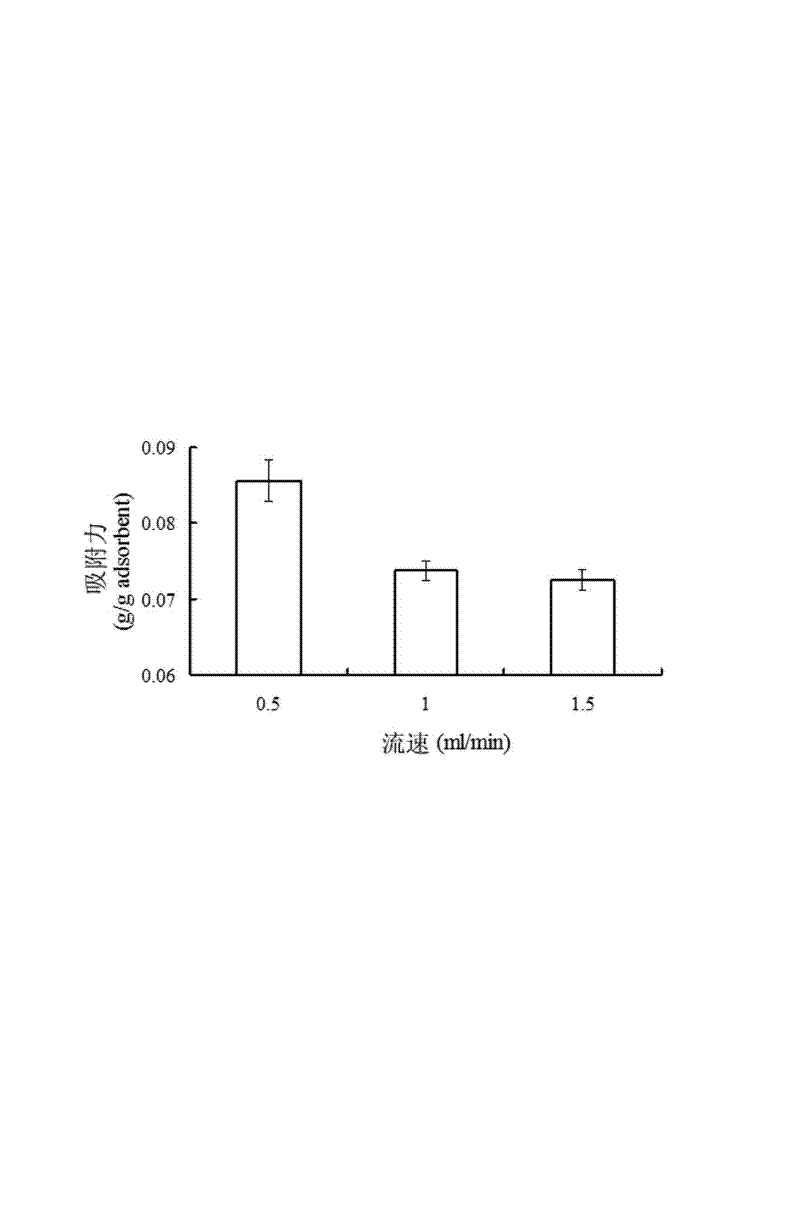

[0068] Weigh an equal mass of pretreated diatomaceous earth and activated carbon and mix them into a chromatographic column with a volume of 40 ml. After it settles, keep the column temperature at 25°C and equilibrate 5 column volumes with ultrapure water Afterwards, the filtrate containing fructooligosaccharides obtained by the method in Example 1 is loaded on the chromatographic column with a flow rate of 1 ml / min, and the loading volume is 40 ml, and then washed with ultrapure water, and the conductivity is After the value reaches a stable value, use 50 ml of ethanol with a volume fraction of 5%, 10%, 15% and 20% to elute step by step, the flow rate is 1 ml / min, collect one tube for every 5 ml, and detect the oligomerization For fructose content, collect the collected liquid containing fructooligosaccharides, concentrate it to the volume before loading the sample by ro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap