Method for using modular steel hysteresis damper

A variable damper and modular technology, applied in the field of steel hysteresis variable dampers, can solve the problem of not maximizing the energy dissipation effect of the damper, and achieve the effect of easy assembly and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

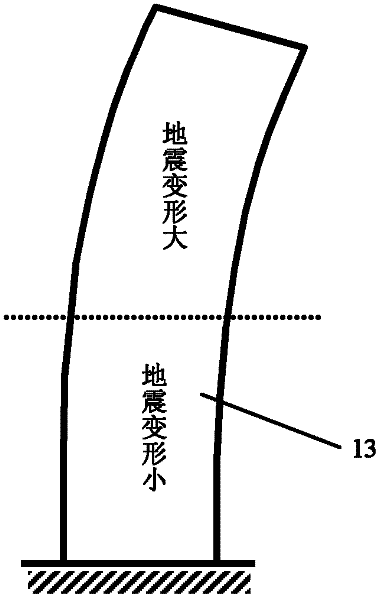

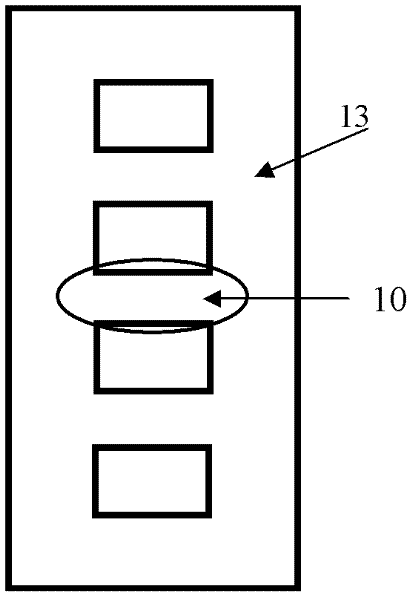

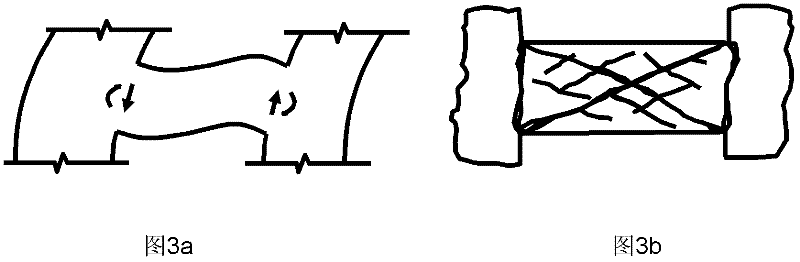

[0024] Specific implementation mode one: as Figure 1-20As shown, the modular steel hysteresis damper in the method of using the modular steel hysteresis damper described in this embodiment includes N energy dissipation layers 1, 2N+2 pressure plates 2, two pairs of splints 3 and two Anchor plate 8, N is a non-zero natural number; the cross section of each splint 3 is L-shaped, and each end between two adjacent energy dissipation layers 1 is provided with a pressure plate 2, and N energy dissipation layers 1 2N+2 pressure plates 2 are stacked alternately to form the main body of the damper. Two pressure plates 2 are respectively provided on the upper end surface and the lower end surface of the damper main body. And it is fixed on a pair of splints 3 through the connecting piece penetrating through the end, and the other end of the damper body with the pressure plate 2 is located between the other pair of splints 3 and is connected through the end through the connection The p...

specific Embodiment approach 2

[0031] Specific implementation mode two: as Figure 7-20 As shown, a plurality of ribs 9 are provided between two vertical surfaces of each splint 3 with an L-shaped cross section in the modular steel hysteresis damper described in this embodiment. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0032] Specific implementation mode three: as Figure 7-20 As shown, the number of N in the modular steel hysteresis damper described in this embodiment ranges from 10 to 40 pieces. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com