Light explosion relief wall capable of being decorated

A decorative and lightweight technology, applied to walls, building components, insulation, etc., can solve the problems of not being able to meet the requirements of wind pressure resistance, poor surface decoration, general fire performance, etc., to achieve good decoration and strong fire performance , Strong wind pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

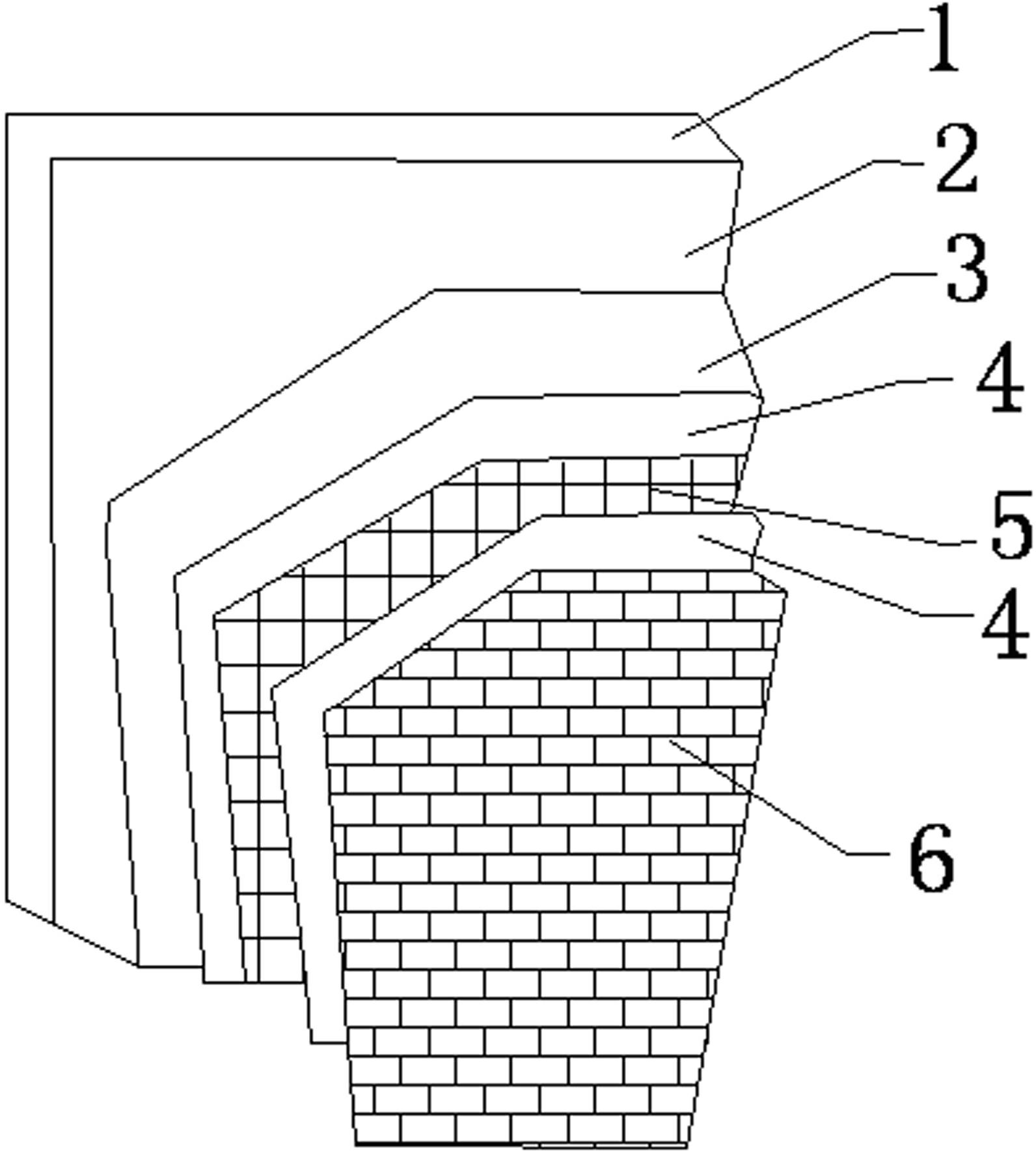

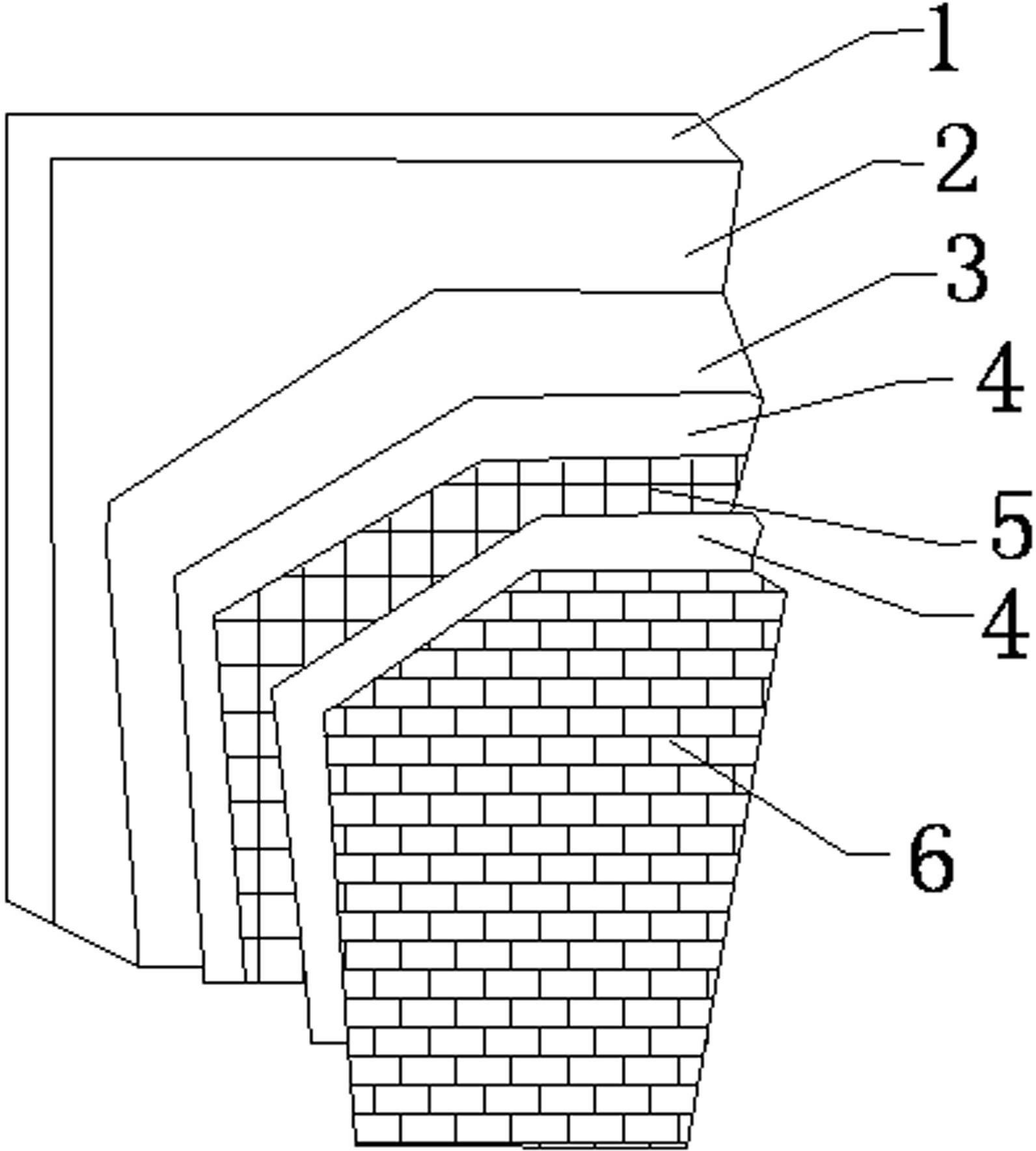

[0016] Such as figure 1 As shown, the decorative light-weight explosion-venting wall described in the embodiment of the present invention is composed of a square tube steel frame 1, a cement fiber board 2, a thermal insulation board, an anti-crack protection layer and a veneer ceramic tile 6. The cement The fiber board 2 is laid and fixed on the square tube steel frame 1, one side of the thermal insulation board is connected with the cement fiber board 2 through adhesive and / or rivets, and the other opposite surface of the thermal insulation board is connected with the anti-crack protective layer Sticking together, the veneer tiles 6 are pasted on the anti-crack protection layer by cement mortar.

[0017] Wherein, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com