Quick construction hanging bracket for external wall of large storage tank

A large-scale storage tank and fast technology, which is applied to the scaffolding of housing structure, housing structure support, housing structure support, etc., can solve the problems of waste of manpower, material resources, low labor efficiency, large number of scaffolds, etc. The effect of enhanced safety and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

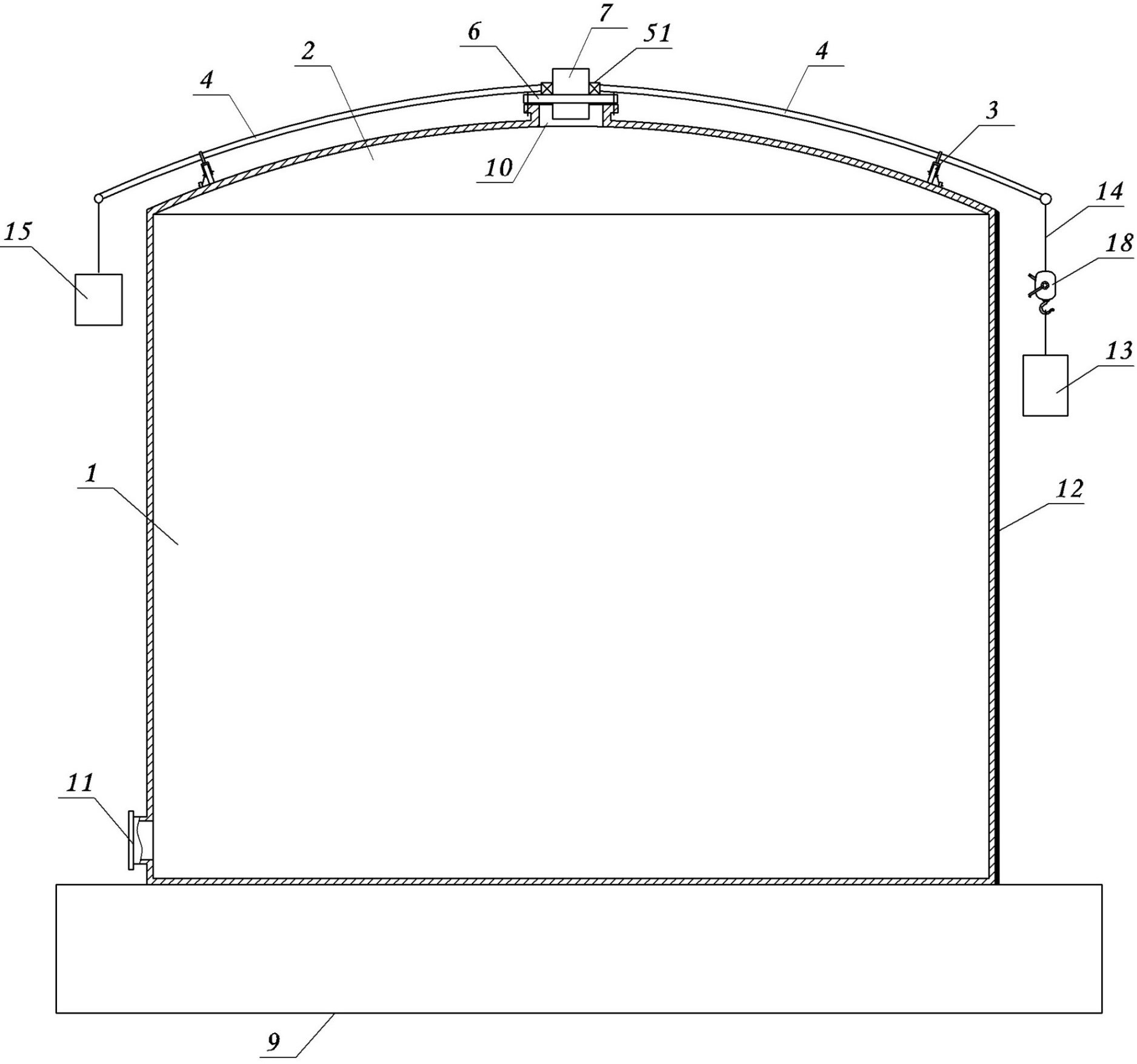

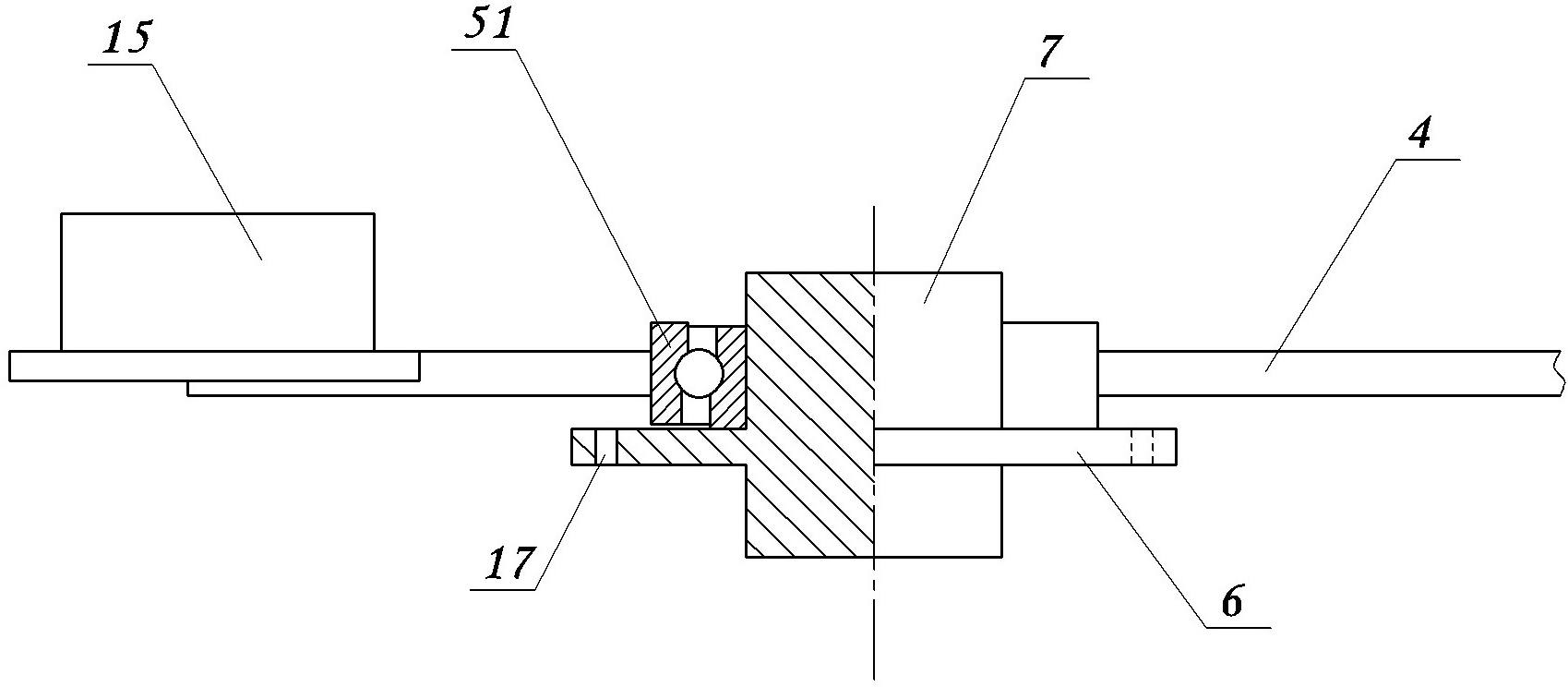

[0023] Example 1: see figure 1 The rapid construction hanger for the outer wall of the large storage tank uses the manhole 10 in the center of the dome of the oil tank as the center of rotation, and a rotating mechanism is set in the center manhole 10. See figure 2 , The rotating mechanism includes a flange 6 that is matched and fixed with the central manhole of the upper end of the oil tank. The center of the flange 6 is vertically fixed with a shaft 7. The outer side of the shaft 7 is sleeved with a roller bearing 51, and the two connecting rods 4 are respectively It is fixed on the outer shell of the roller bearing or on both sides of the bearing seat. The connecting rod 4 matches the arc of the dome on the upper side of the oil tank. One side of the connecting rod 4 protrudes from the tank wall by 1 to 1.5 m, and a wire rope 14 is hung. The end of the wire rope 14 is connected to a hanging basket 13, and the middle of the wire rope 14 is provided with a lever hoist 18; A ...

Embodiment 2

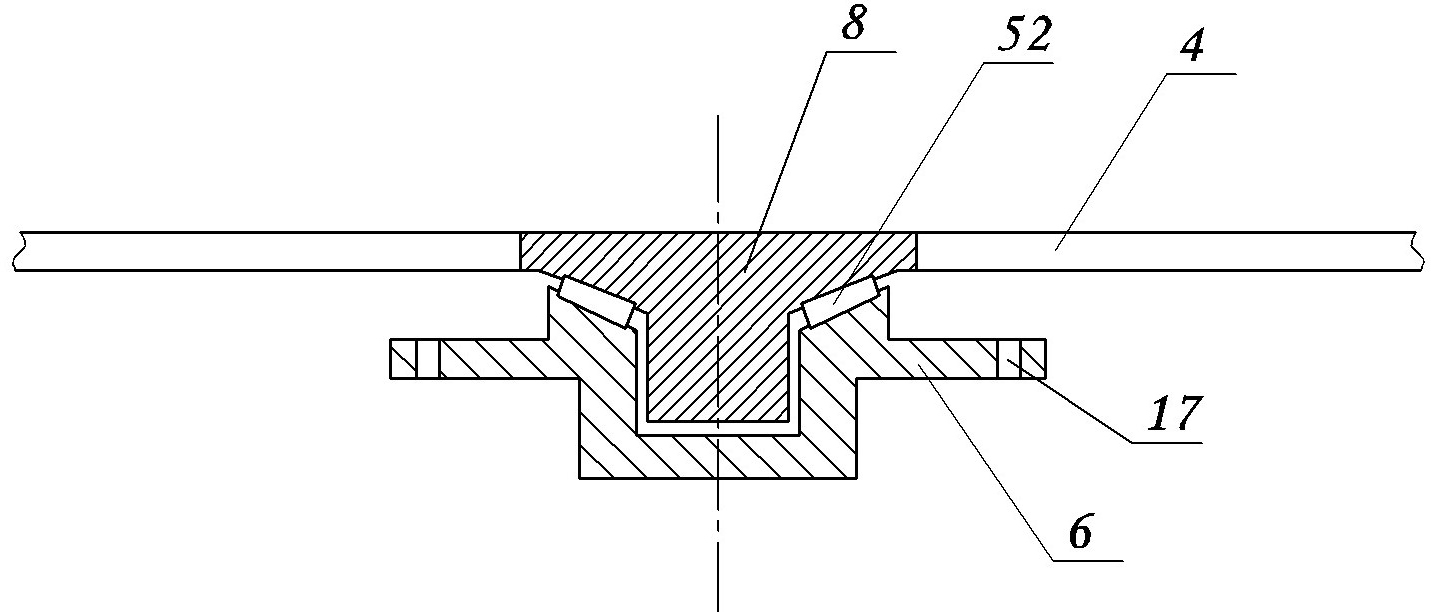

[0025] Example 2: see image 3 The content is basically the same as that of the first embodiment, and the similarities are not repeated. The difference is that the rotating mechanism includes a flange 6 that is matched and fixed with the central manhole of the upper end of the oil tank, and the center of the flange 6 is provided with a through hole or In the blind hole, a central rotating shaft 8 is sleeved in the hole through a thrust bearing, and two connecting rods 4 are fixed on both sides of the central rotating shaft 8 respectively.

Embodiment 3

[0026] Example three: see Figure 4 The content is basically the same as the first embodiment, and the similarities will not be repeated. The difference is that the connecting rod of this embodiment is a sleeve type, which can expand and contract to meet the construction needs of oil tanks of different diameters. The sleeve type connecting rod includes two inner sleeve rods (tubes) 41a and 41b at both ends, an outer sleeve 42 in the middle, and a tightening screw 43 is arranged between the inner and outer sleeves for fixing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com