Flexible pipe assisted type pipeline returning method

A kind of pipeline back towing, auxiliary technology, applied in the direction of pipeline laying and maintenance, pipe/pipe joints/pipe fittings, mechanical equipment, etc. Achieve the effect of reducing ground uplift or formation fracturing, increasing flow channels, and reducing circulation pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

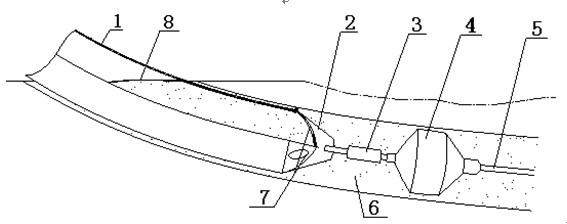

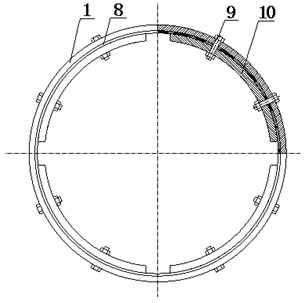

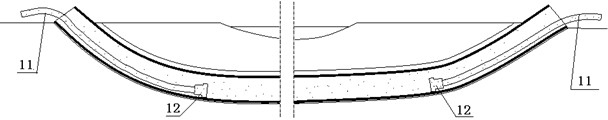

[0030] Embodiment 1: The hose-assisted pipeline pull-back method of the present invention is different from the conventional closed pull-back method; according to the characteristics of the pipeline pull-back process, the present invention changes the conventional closed puller into an open puller 2, for To prevent the mud from entering the pipeline from fouling the inside of the pipeline, a hose 8 with matching specifications is introduced inside the pipeline 1 to isolate the incoming mud 6 from the inner wall of the pipeline. The construction process of the hose-assisted pipeline pullback method of the present invention is as follows: figure 1 , 2 , 3 shown.

[0031] The hose-assisted pipeline dragging method of the present invention, the specific operation is implemented according to the following steps:

[0032] (1) After the welding of the pipeline 1 is completed, the hose 8 is pulled into the pipeline through the traction steel rope, and tightly assembled with the pipe...

Embodiment 2

[0037] Embodiment 2: In the hose-assisted pipeline dragging method of the present invention, the hose used can be a single-layer hose 16, and the single-layer hose can be made of a high-strength water-proof material 13. Make the joint edge 14 on the side, install three longitudinal ribs 15 on the outside of the high-strength water-proof material 13, roll up the high-strength water-proof material 13 processed with the longitudinal rib 15 and the joint edge 14 longitudinally, Make single-layer hose 16 on the mould, its structure and manufacturing process are as Figure 4 As shown, the single-layer hose 16 has the characteristics of high tensile strength, watertightness, and wear resistance.

Embodiment 3

[0038] Embodiment 3: In the hose-assisted pipeline dragging method of the present invention, the hose used usually needs to be made of a composite hose 21 by physical combination of more than one high-strength wear-resistant material. Its structure and manufacturing process are as follows Figure 5 As shown, the pipe material of the composite hose 21 can be made of high-strength wear-resistant material A17, water-proof material 18 and high-strength wear-resistant material B19, and the composite material 20 is processed by painting adhesive materials between the two materials. The two sides of the composite material 20 are made with joint edges 14, and seven longitudinal ribs 15 are installed on the composite material along the longitudinal direction, and the materials are combined along the joint edges 14 to form a composite hose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com