Gas-solid two-phase flow parameter detector

A technology of parameter detection and phase flow, which is applied in the field of gas-solid two-phase flow parameter detection devices, can solve problems such as inability to effectively measure a single flow parameter, and achieve the effects of simple installation, strong anti-interference ability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

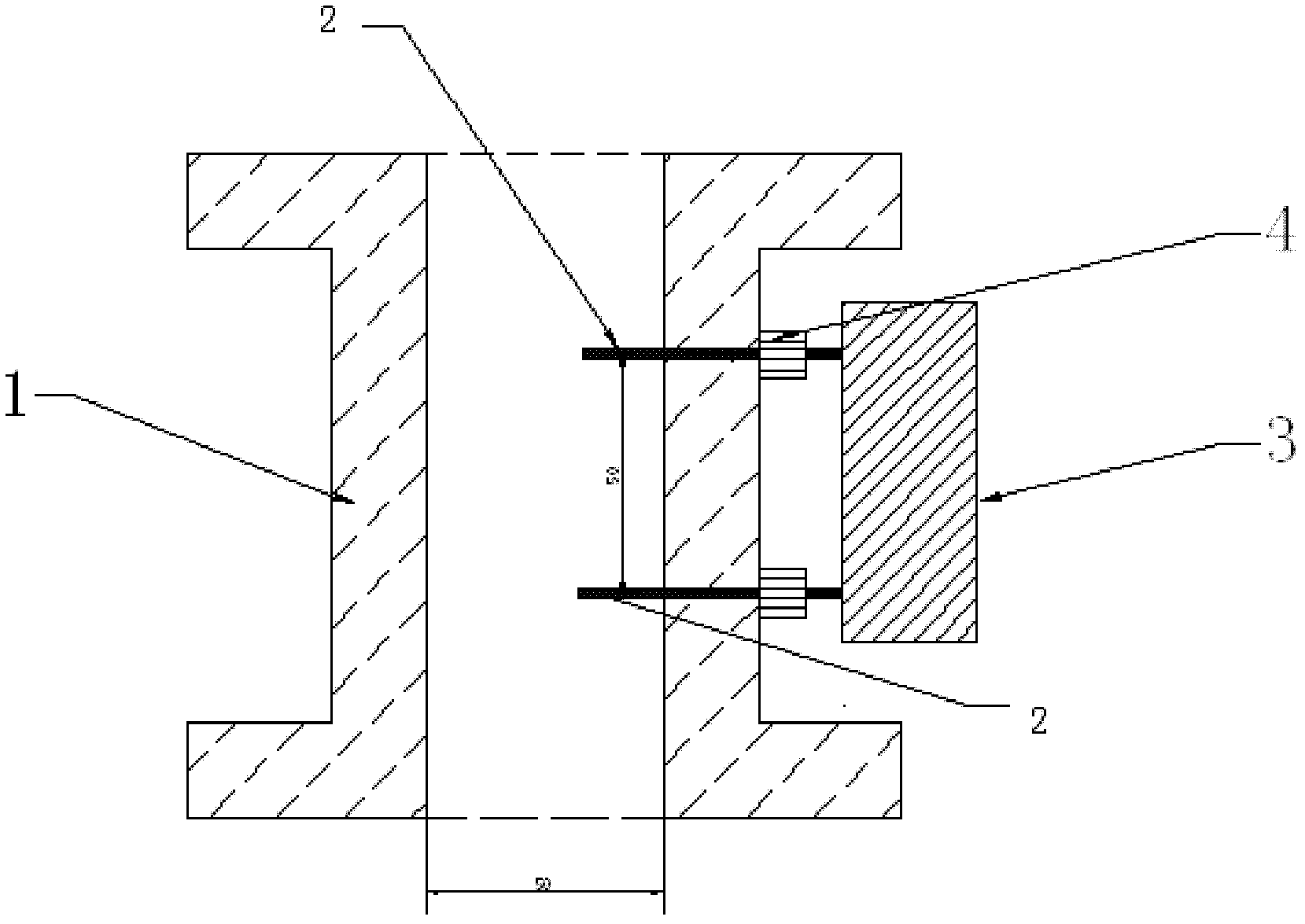

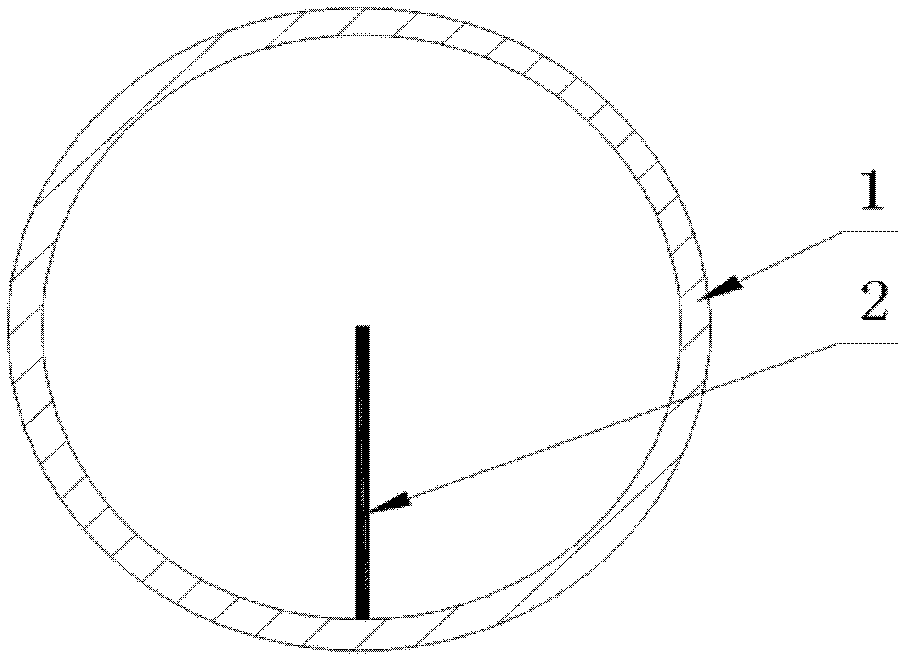

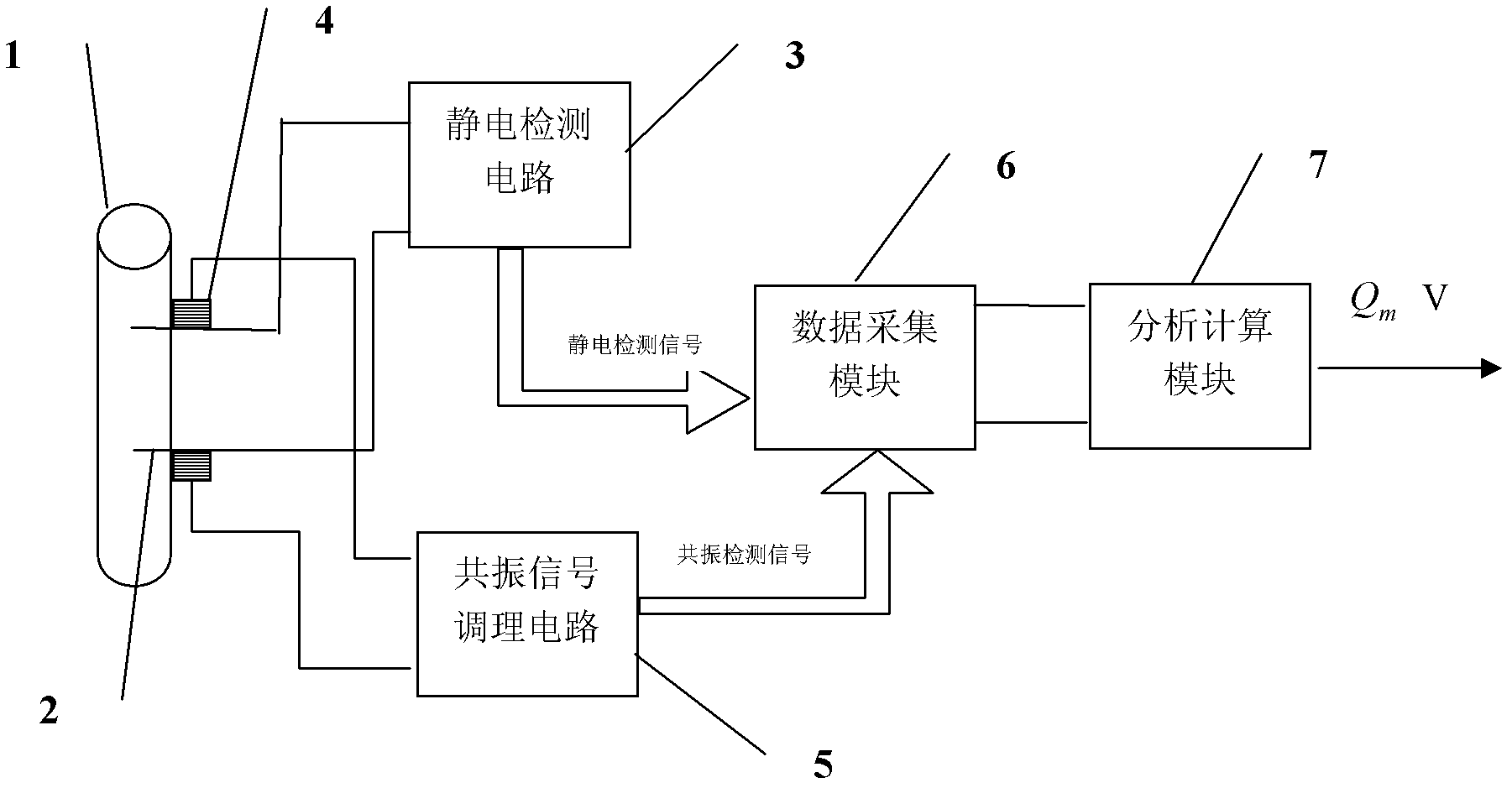

[0034] See Figure 1 and figure 2 , a probe 2 is respectively installed upstream and downstream in the pneumatic conveying pipeline 1 (50 mm apart in this embodiment), and a piezoelectric sensor 4 is installed on the outside of the pipeline where the probe 2 is located. 3 connections. The static detection signal output by the static detection circuit 3 and the resonance signal output by the piezoelectric sensor 4 are connected to the data acquisition module 6 and the analysis and calculation module 7 through the resonance signal conditioning circuit.

[0035] The working principle of the electrostatic detection circuit and piezoelectric sensor combined measurement method of gas-solid two-phase flow parameters is as follows: In pneumatic transmission, due to the collision between solid particles, the collision between particles and the pipe wall, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com