Method for detecting coating rate of microcapsule core material

A detection method, microcapsule technology, applied in the direction of color/spectral characteristic measurement, to achieve the effect of overcoming inaccurate detection data, stable test results, and good repeatability of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

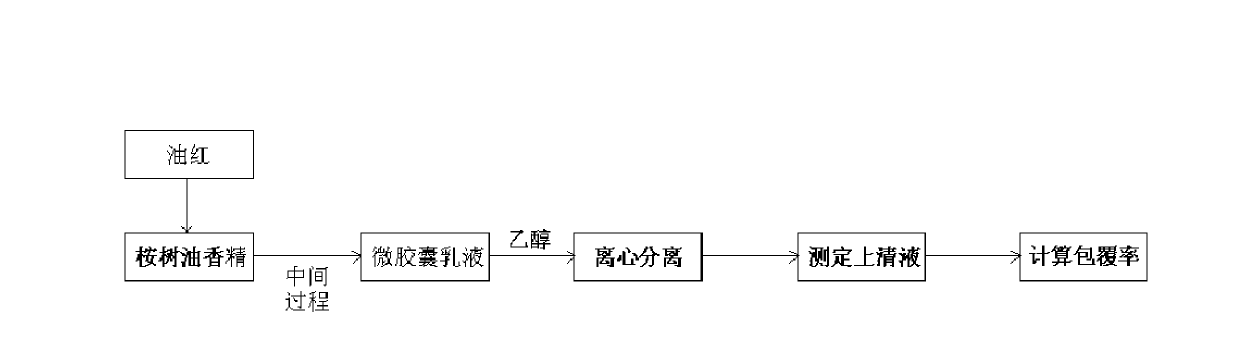

Image

Examples

Embodiment 1-3

[0021] Embodiment 1-3: a kind of detection method of microcapsule core material coating rate,

[0022] step one. The core material system is obtained by uniformly blending the oil red with the oily core material, wherein the mass ratio between the oil red and the oily core material is as shown in Table 1:

[0023] Table 1

[0024] oil red Oily core material Example 1 0.005 1 Example 2 0.0063 1 Example 3 0.007 1

[0025] Annotate embodiment 1-3 oily core material is: embodiment 1 is peppermint essence, embodiment 2 is eucalyptus oil essence, embodiment 3 is DEET;

[0026] Step two. Adding the core material system in step 1 to the aqueous solution in which the wall material is dissolved, and going through a series of coating processes to form a microcapsule emulsion, the microcapsules are composed of the core material system and the wall material coated on the surface of the core material system, The wall material composition of descri...

Embodiment 4-6

[0033] Embodiment 4-6: A kind of detection method of microcapsule core material coating rate

[0034] step one. The oil red and the oily core material are uniformly blended to obtain a core material system, wherein the mass ratio between the oil red and the oily core material is as shown in Table 2:

[0035] Table 2

[0036] oil red Oily core material Example 4 0.005 1 Example 5 0.0063 1 Example 6 0.007 1

[0037] Step two. Adding the core material system in step 1 to the aqueous solution in which the wall material is dissolved, and going through a series of coating processes to form a microcapsule emulsion, the microcapsules are composed of the core material system and the wall material coated on the surface of the core material system, The wall material composition of described embodiment 1-3 is: embodiment 1 is gelatin, embodiment 2 is gum arabic, embodiment 3 is the mixture of gelatin and arabic gum;

[0038] Step three. adding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com