Planar carburizing sample determination method based on magnetic method

A sample measurement and carburizing technology, applied in the direction of material magnetic variables, etc., can solve the problems that non-destructive testing cannot be achieved, and the carburized layer cannot guarantee the detection efficiency and accuracy at the same time, so as to achieve fast, accurate and repeatable measurement results Good performance and optimized database effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

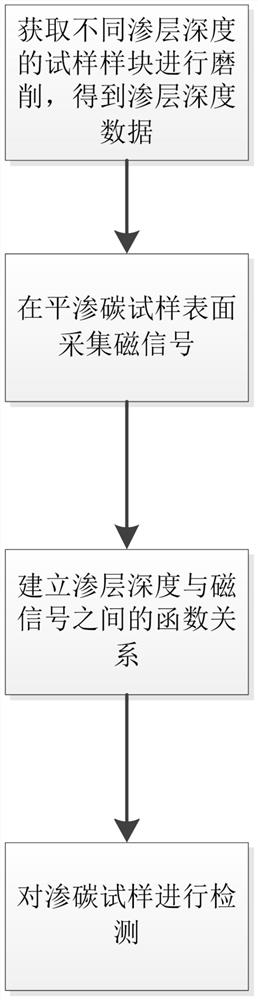

[0020] Specific implementation mode one: combine figure 1 To illustrate the present embodiment, the planar carburized sample magnetic method measuring method of the present embodiment includes:

[0021] Step 1. Select 10 sample blocks of each of the 6 carburized layer depths, and grind each sample block according to 0.06mm, 0.04mm, 0.06mm, 0.04mm (not limited to 4, but can be multiple times) The rule of depth is to grind the carburized layer depth in stages, and each grinding can obtain a carburized layer depth data, which constitutes a carburized layer depth data set;

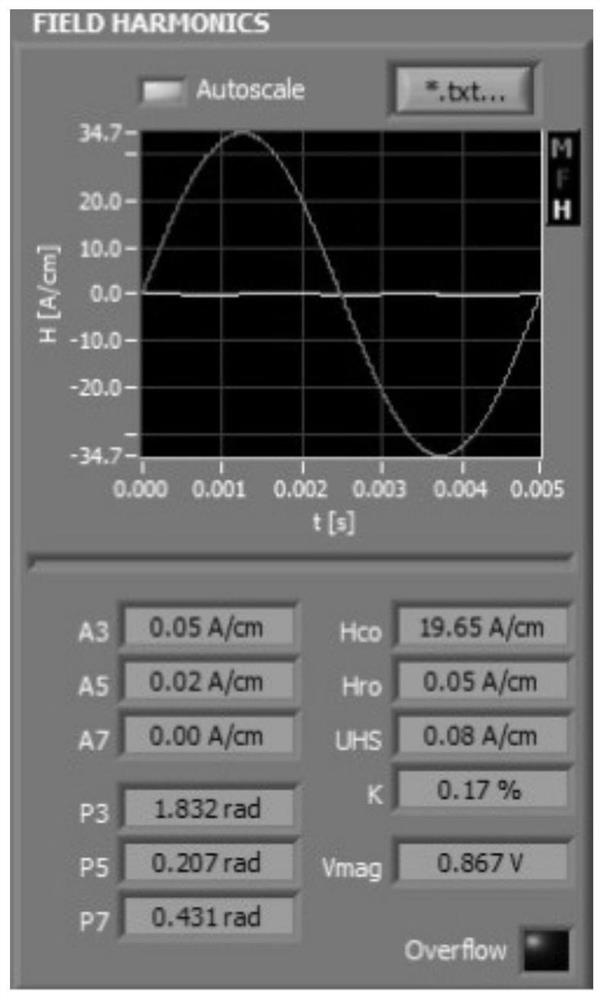

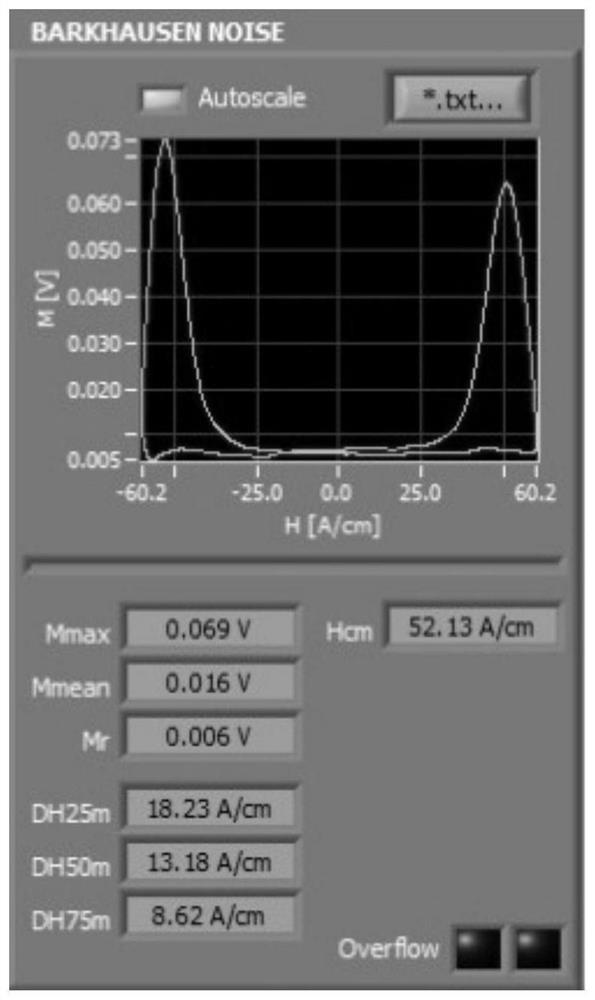

[0022] Step 2. Using the 3MA penetration depth tester, the electromagnetic coil probe is used to collect magnetic signal parameters in a non-destructive and only contact manner on the surface of the plane carburized sample. The magnetic signal includes the tangential magnetic field intensity time signal and the Barkhausen noise signal. , incremental magnetic permeability signal and multi-frequency eddy curren...

Embodiment

[0054] Utilize the inventive method to gather experimental data, have carried out preliminary data processing according to experimental data, find that data correlation coefficient r ∧ 2 is lower than 0.7857 in the calculation process, less than 0.8, data correlation is relatively poor, analysis causes the reason of this phenomenon to be, In the process of data collection and entry, some invalid data existed due to the influence of material surface quality or operational errors. After statistical combing, this part of the data was deducted, and the curve was corrected to obtain a better correlation coefficient. The experimental results Such as figure 1 , Figure 2a-2d shown.

[0055] After obtaining the curve and detection equation, take carburized sample blocks with different depths of carburized layers for testing, and test the tested samples by metallographic method, and compare the test results. The comparison results are shown in Table 2 and Table 3 . According to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com