Component mounting system, its control device and component mounting method

A technology of control device and installation system, applied in the direction of electrical components, electrical components, etc., can solve the problems of products becoming waste products and mass production, and achieve the effect of preventing mass production of waste products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

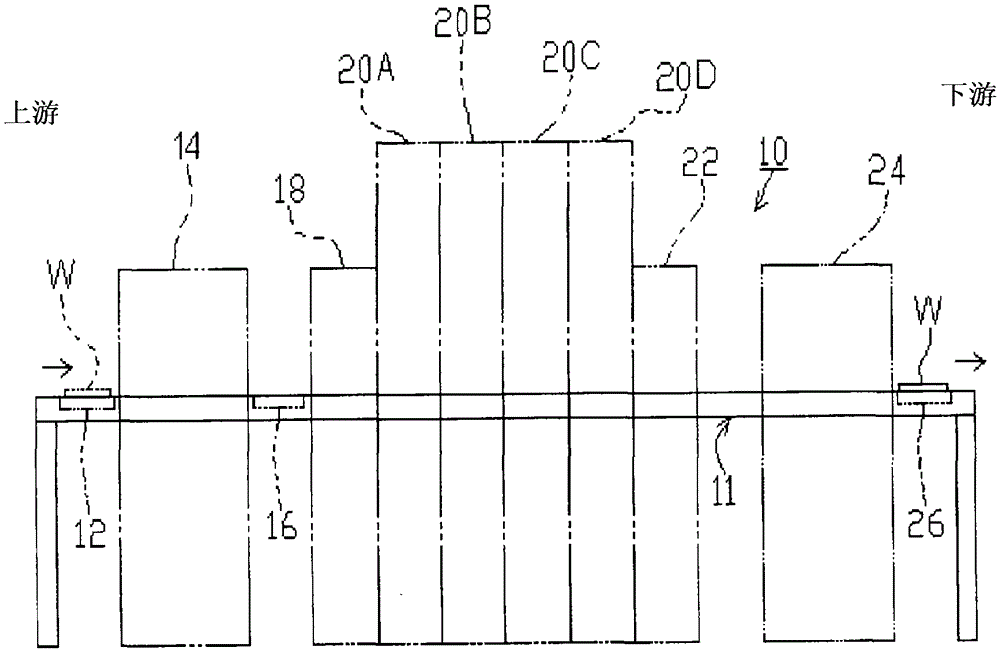

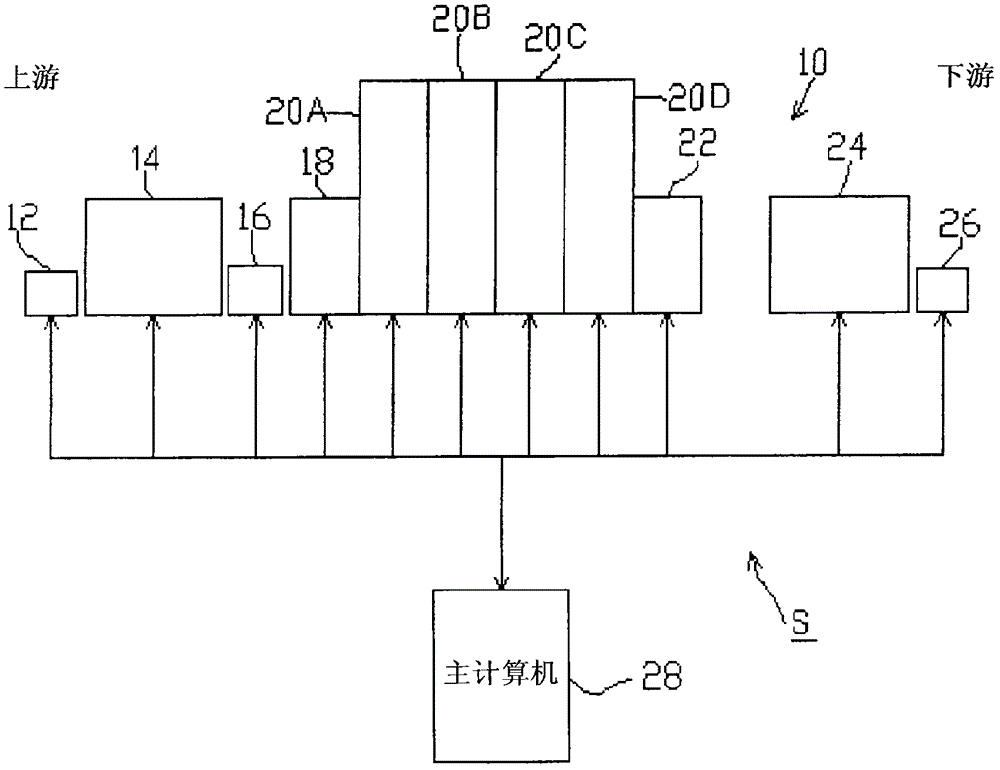

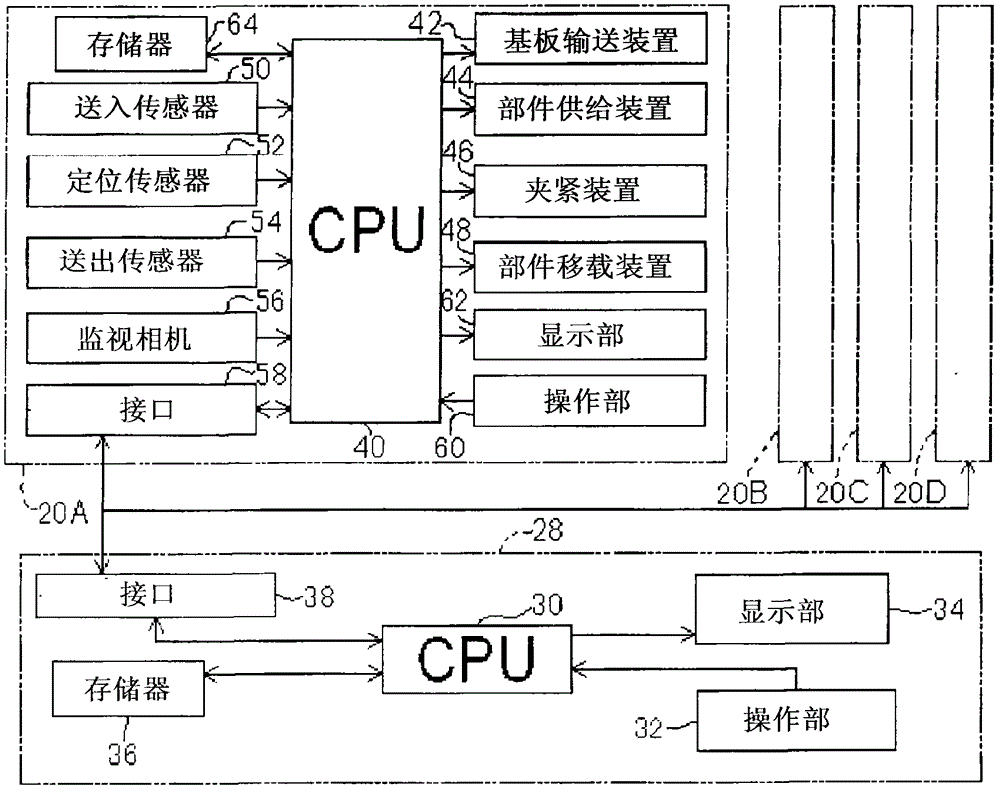

[0032] Below, according to Figure 1 to Figure 5A component mounting system, a control device thereof, and a component mounting method as one embodiment of the present invention will be described. Here, the component mounting system according to the present invention is applicable not only to a system for mounting electronic components such as LSI packages on a printed circuit board, but also to an automobile manufacturing system for mounting mechanical components such as springs on a panel. That is, the concept of the components according to the present invention includes not only electronic components such as transistors but also mechanical components such as bolts.

[0033] (Schematic configuration of the installation line)

[0034] Such as figure 1 As shown, the mounting line 10 includes a transfer table 11 called a single track conveyor, and mounts electronic components (not shown) on the substrate W conveyed on the transfer path of the transfer table 11 . On the insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com