Ultraviolet-curable adhesive agent composite, adhesive agent layer, adhesive sheet, and manufacturing method therefor

A manufacturing method and adhesive technology, which are applied in the direction of polymer adhesive additives, non-polymer adhesive additives, non-polymer organic compound adhesives, etc., can solve the problem of inability to use universal solvents, cumbersome and other issues, to achieve excellent refractive index and adhesive force, enhance mechanical properties, and enhance the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

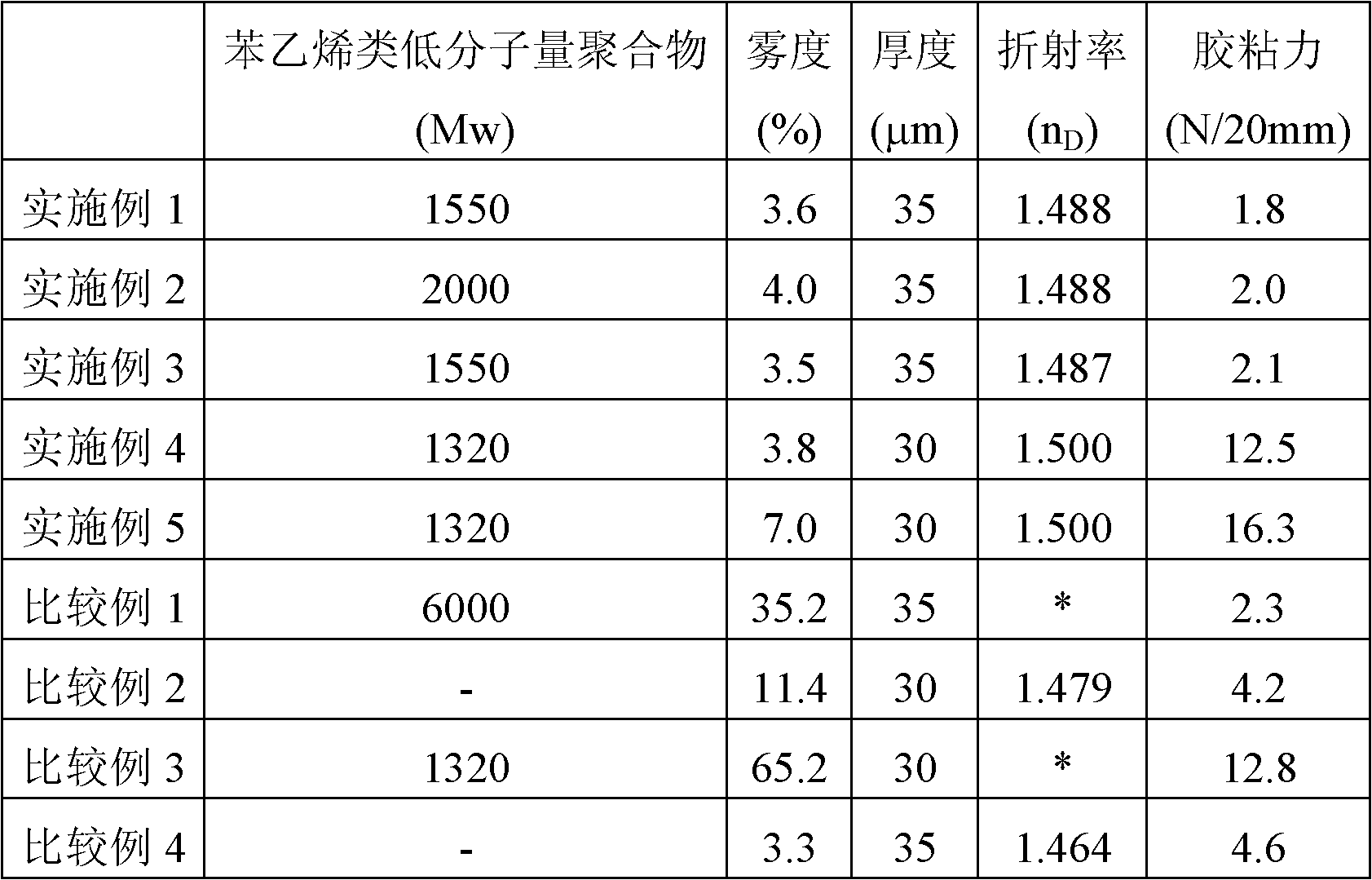

Examples

preparation example Construction

[0061]The preparation method of the above-mentioned adhesive composition is not particularly limited as long as it includes the above-mentioned components. From the viewpoint of process simplification, it is preferably prepared by the following method: first, prepare a dispersion liquid of metal nanoparticles and an aromatic low-molecular-weight polymer The solids obtained by mixing and drying the solutions of the solids were then dissolved in the monomer components. The dispersion medium of the metal nanoparticle dispersion liquid is water or an organic solvent, and the solution of the aromatic low-molecular polymer can be used in the form of a solution in an organic solvent such as toluene, ethyl acetate, or methyl ethyl ketone. A mixture of a metal nanoparticle dispersion and an aromatic low-molecular polymer solution is usually dried at room temperature without heating to obtain a solid by removing the solvent. In addition, at the time of preparation of the adhesive compos...

Embodiment 1

[0089] 100 parts of n-butyl acrylate, 1 part of 4-hydroxybutyl acrylate, 0.05 parts of a photopolymerization initiator (manufactured by Ciba Corporation of Japan, Irgacure 651) and 0.4 parts of a photopolymerization initiator (manufactured by Ciba Corporation of Japan, Irgacure 184) After mixing and fully replacing nitrogen, intermittently irradiate for 5 minutes with a high-pressure mercury lamp (UVA illuminance: 0.271W / cm 2 ) to obtain a viscous slurry. The degree of polymerization of monomers in this slurry was 12.5%. 1.0 parts of trimethylolpropane triacrylate and 20 parts of styrene low-molecular weight polymer (SX-85, weight average molecular weight Mw=1550, manufactured by Yasuhara Chemical Co., Ltd.) were blended into the slurry, and uniformly mixed to prepare an ultraviolet curing type Adhesive composition. Apply this ultraviolet curable adhesive composition to the polysiloxane-treated, 38 μm polyethylene terephthalate (PET) film (DIAFOIL MRN38, manufactured by Mits...

Embodiment 2

[0091] Except that the styrene low-molecular-weight polymer in Example 1 was changed to a styrene low-molecular-weight polymer (SX-100, Mw=2000, manufactured by Yasuhara Chemical Co., Ltd.), the adhesive sheet was produced in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap