Yoga mat and manufacturing method thereof

A production method and yoga mat technology, which are applied to flat products, other household appliances, and cushions that absorb movement and vibration, etc., can solve the problem of low friction between the bottom of the cushion body and the ground, inconvenient elasticity for folding and storage, and friction on the upper end surface of the cushion body. Small and other problems, to achieve the effect of corrosion resistance and strong adhesion, superior soft texture, and improved comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order for those skilled in the art to further understand the features and technical content of the present invention, please refer to the following detailed description and accompanying drawings of the present invention.

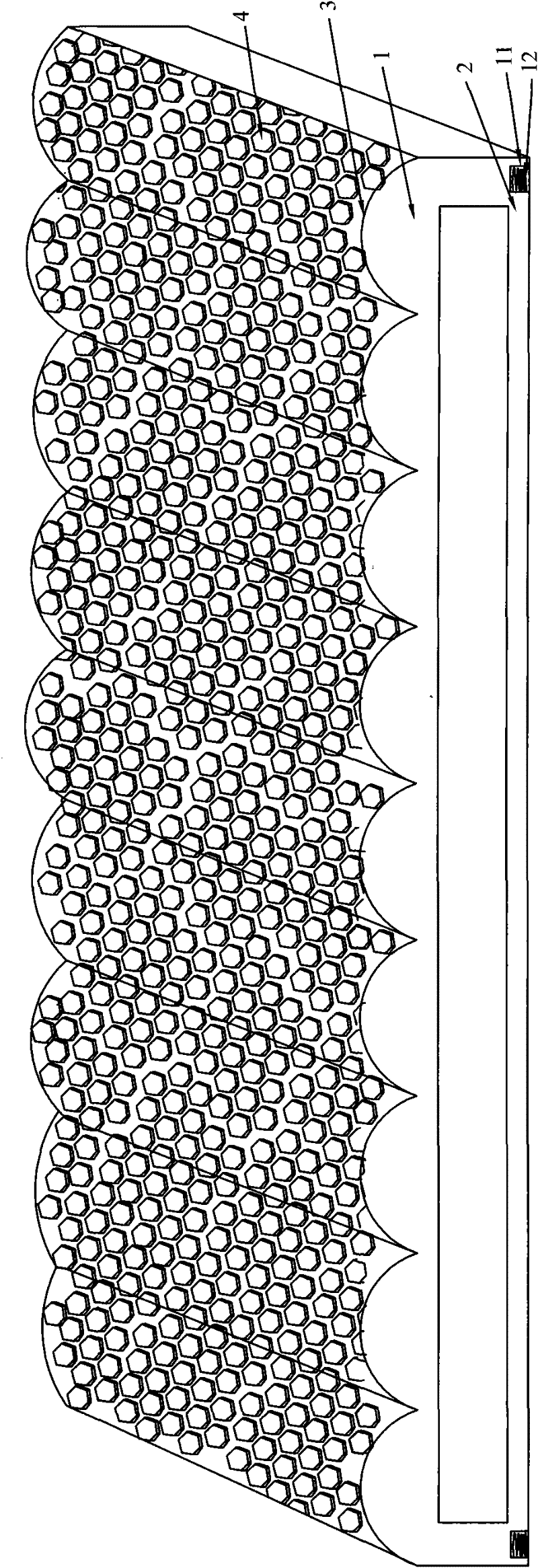

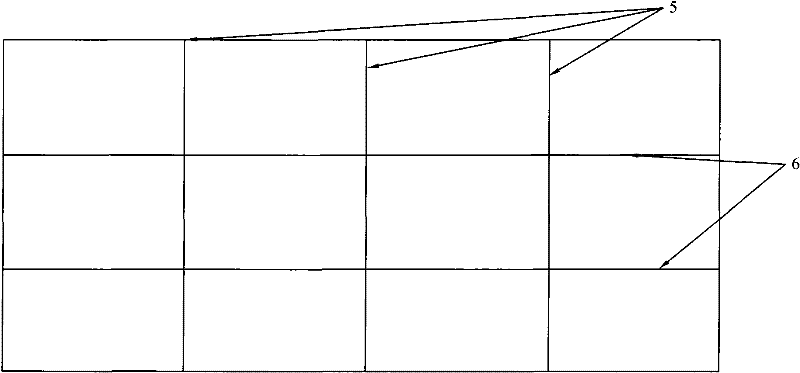

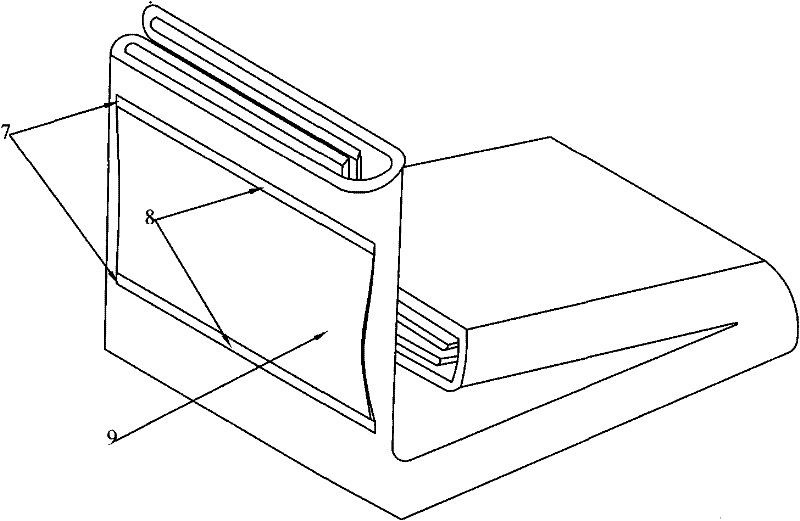

[0034] see Figure 1 to Figure 4 As shown, the present invention provides a yoga mat, including a mat body, wherein the mat body includes a foam core layer located inside and a silicone pad body surface layer coated on the outside of the pad core layer. The surface layer of the cushion body includes an upper surface layer 1 located at the upper end for contact with the human body and a lower surface layer 2 located at the lower end in contact with the ground. The upper surface layer is uniformly formed with a plurality of columnar ribs 3, and the outer surface of the columnar ribs 3 There are also six diamond-shaped protrusions 4 evenly distributed, the pad body is rectangular, and at least two nylon fixing lines are laid and bonded between the pad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com