Processing technique of valve parts in ball valve with hard seal structure

A kind of processing technology and hard sealing technology, which is applied in the processing technology field of the valve parts in the hard sealing structure ball valve, can solve the problems of difficult to ensure the smoothness of the processing surface, reduce the service life of the tool, and the cumbersome conversion of the mold, so as to save the replacement of the card The time, prolong the service life, ensure the effect of smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

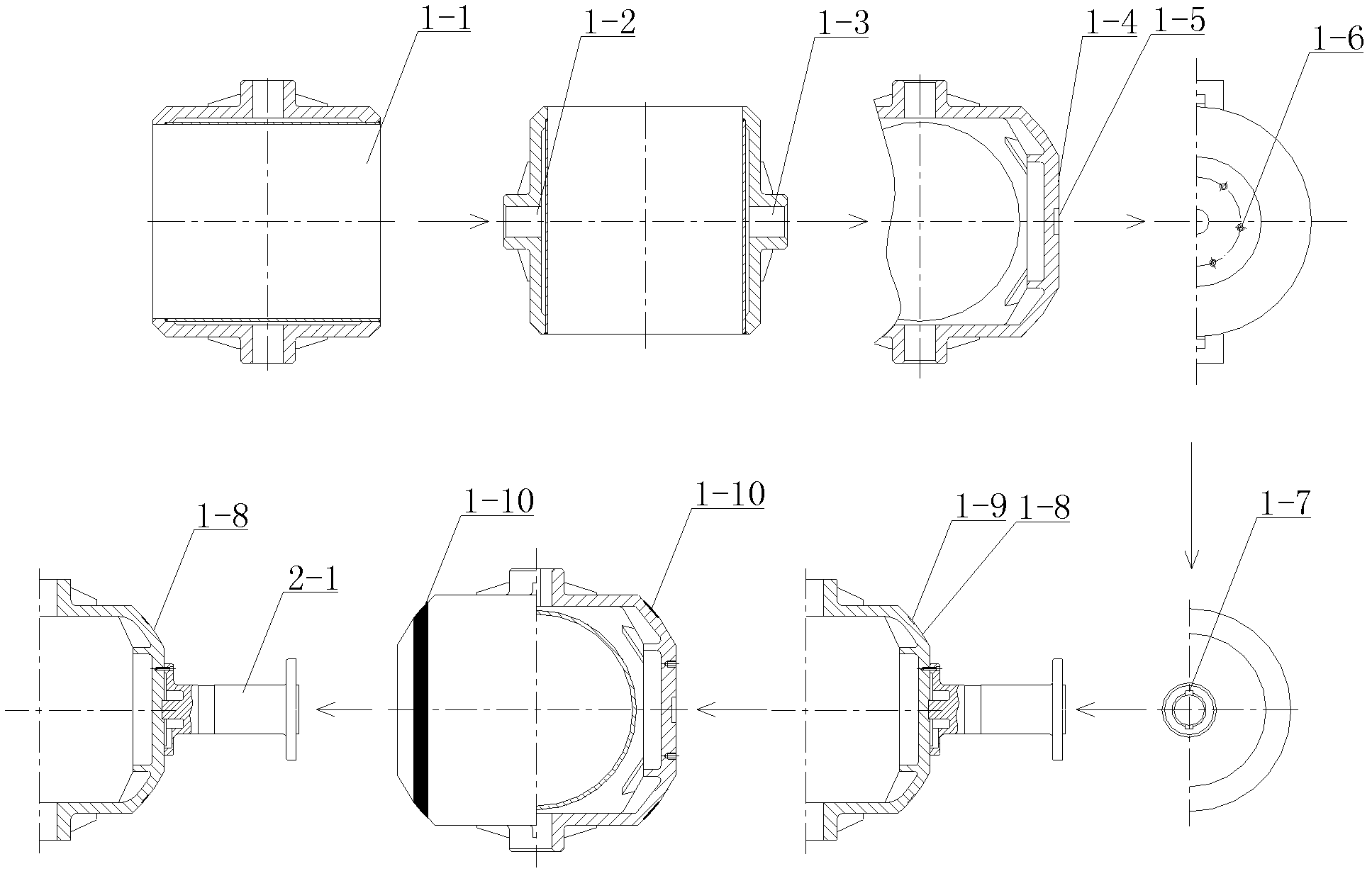

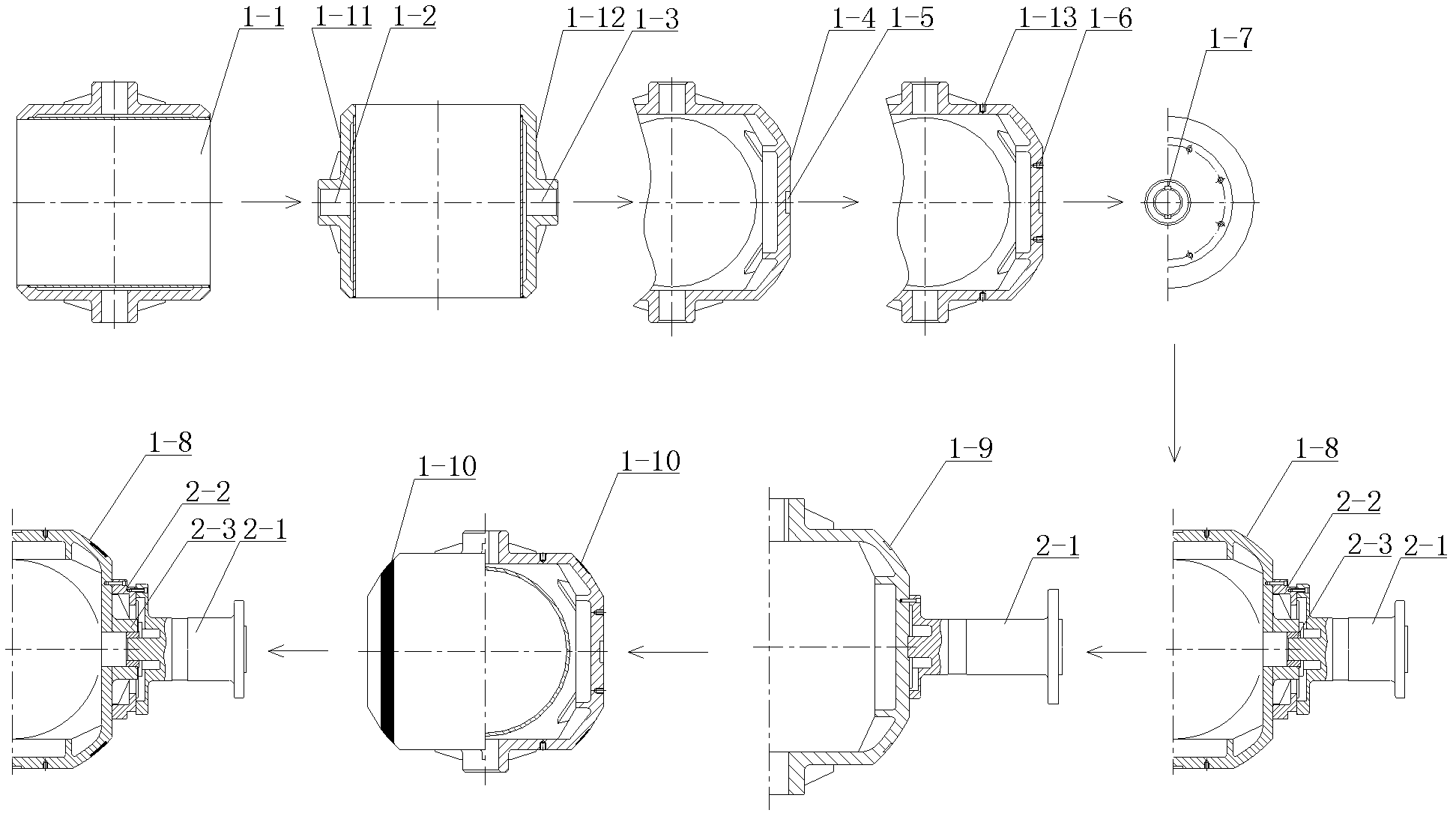

[0031] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0032] see Figure 1-4 , a process for processing valve parts in a hard-sealed structure ball valve, including the following processes:

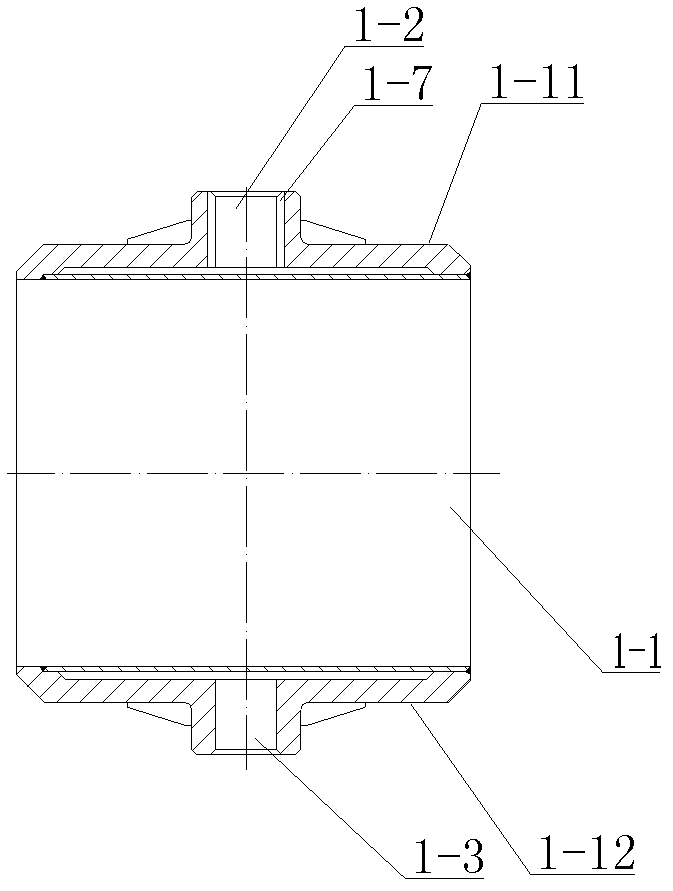

[0033] 1) Car channel hole 1-1, so that the dimensional accuracy of the channel hole meets the design requirements;

[0034] 2) Bore the upper and lower valve shaft holes so that the dimensional accuracy and coaxiality of the upper valve shaft hole 1-2 and the lower valve shaft hole 1-3 meet the design requirements;

[0035] 3) Boring the two sides 1-4 and the process stop 1-5, so that the flatness of the side and the parallelism with the upper and lower valve shaft holes meet the design requirements, and the process stop is set at the center of the side of the valve;

[0036] 4) Drill and tap the process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com