Electronic mechanical brake and automobile

An electromechanical brake and brake disc technology, applied in the automotive field, can solve the problems of high assembly size accuracy, complex brake assembly assembly, poor mechanical strength, etc., and achieve simple mechanism structure, good real-time braking, and easy The effect of manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

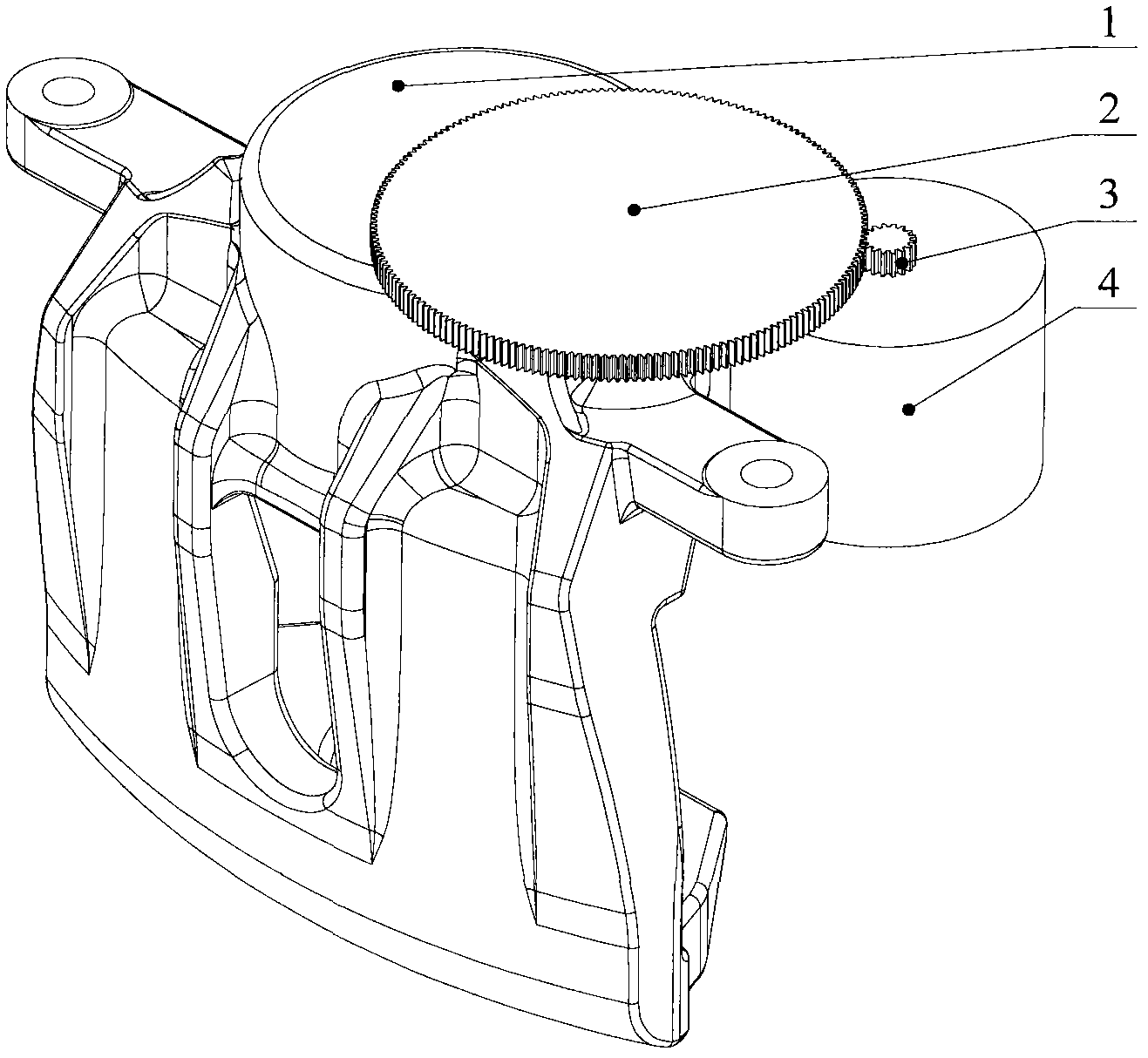

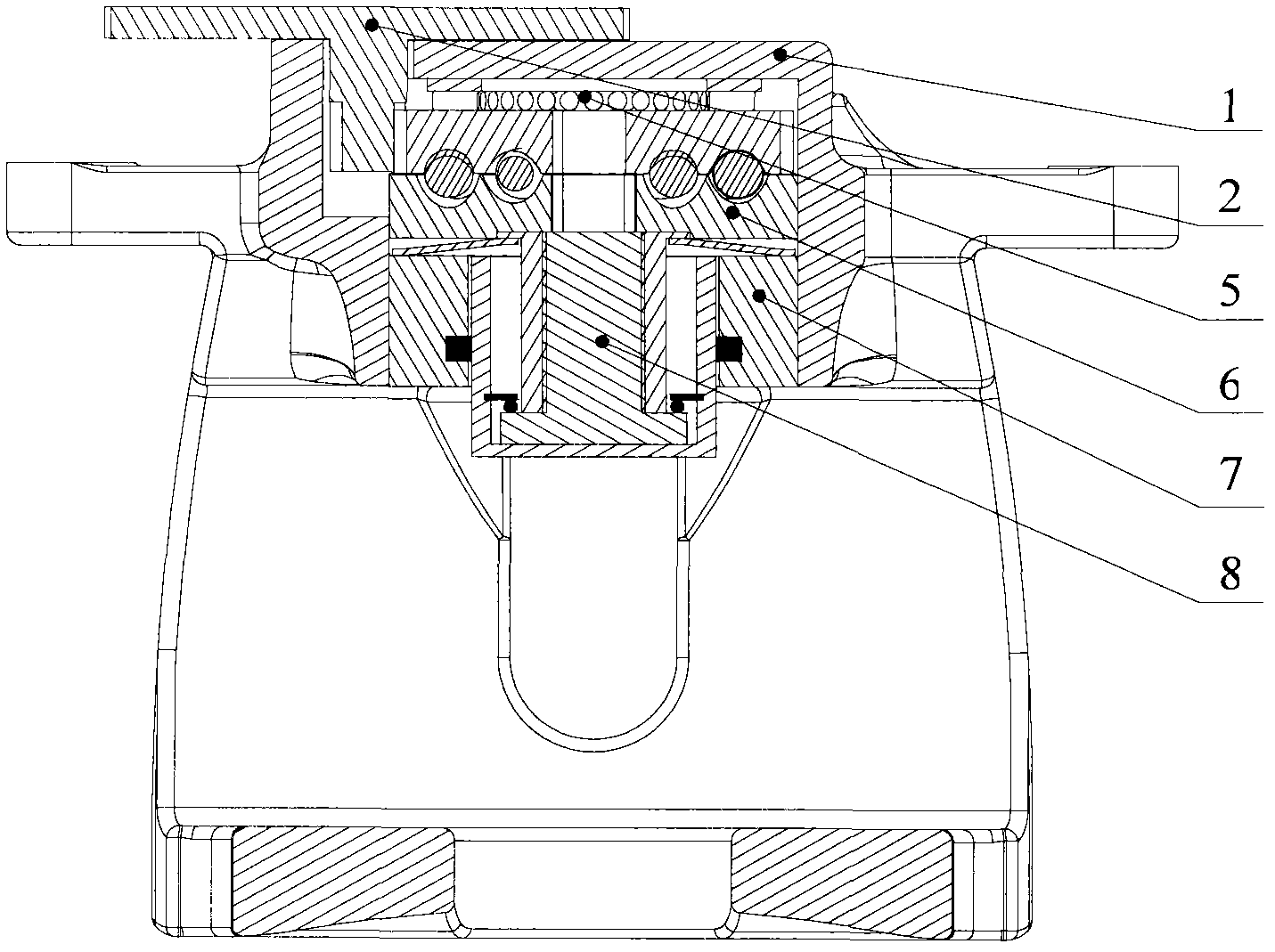

[0029] Such as figure 1 , 2 As shown, in this embodiment, the electromechanical brake includes a caliper body 1, a friction plate, a brake disc, a power mechanism that can push the friction plate to move forward to clamp the brake disc, and can automatically adjust the movement mechanism and the friction plate. The gap self-adjusting mechanism 8 of the braking gap between them, and the friction plates are arranged in front of the gap self-adjusting mechanism 8 .

[0030] Wherein, the power mechanism includes a motor 4, a reduction gear mechanism, and a motion mechanism that converts the rotary motion of the motor 4 into a linear motion; the reduction gear mechanism is located between the motor and the motion mechanism, and the input end of the reduction gear mechanism is connected to the The output shaft is connected, and its output end is connected with the movement mechanism. The reduction gear mechanism and the motor 4 are installed outside the caliper body 1, and the move...

Embodiment 2

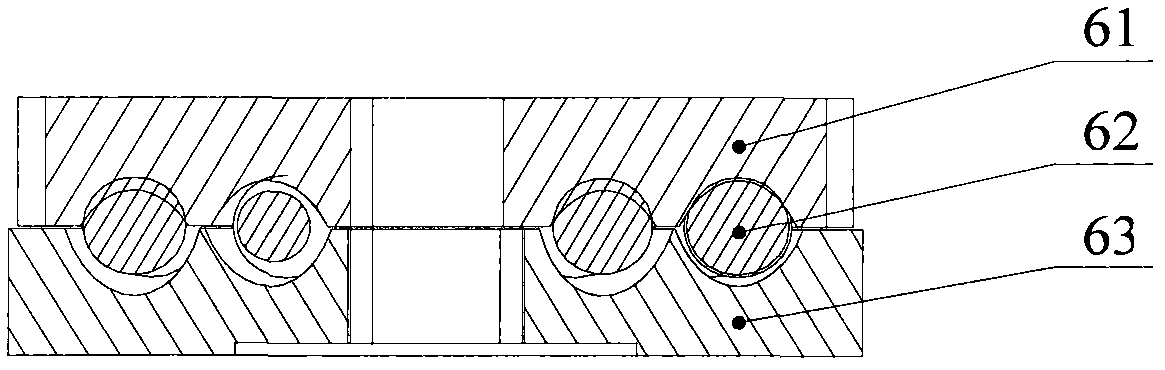

[0047] The difference between this embodiment and Embodiment 1 is that this embodiment does not have the gap self-adjusting mechanism 8 in Embodiment 1. Wherein, the front end of the lower swash plate 63 can be in direct contact with the friction plate, and the brake can be realized by eliminating the gap between the brake disc and the friction plate.

[0048] Other structures and uses in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com