Disc-shaped train brake device and lever used thereby

A technology of braking device and lever, applied in the field of disc train braking device and lever, to achieve the effect of safe and effective braking, timely supply and timely after-sales service

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

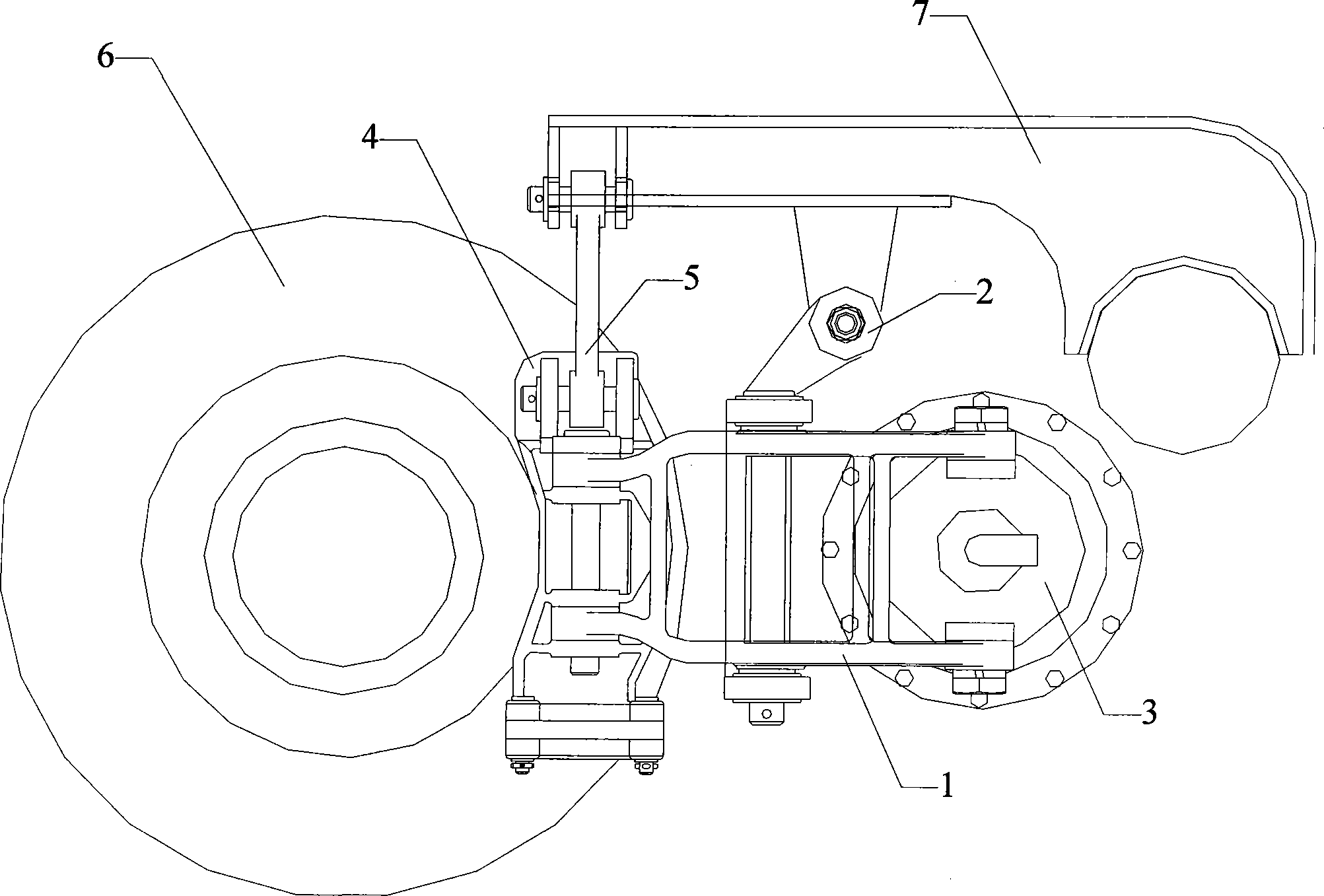

[0038] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

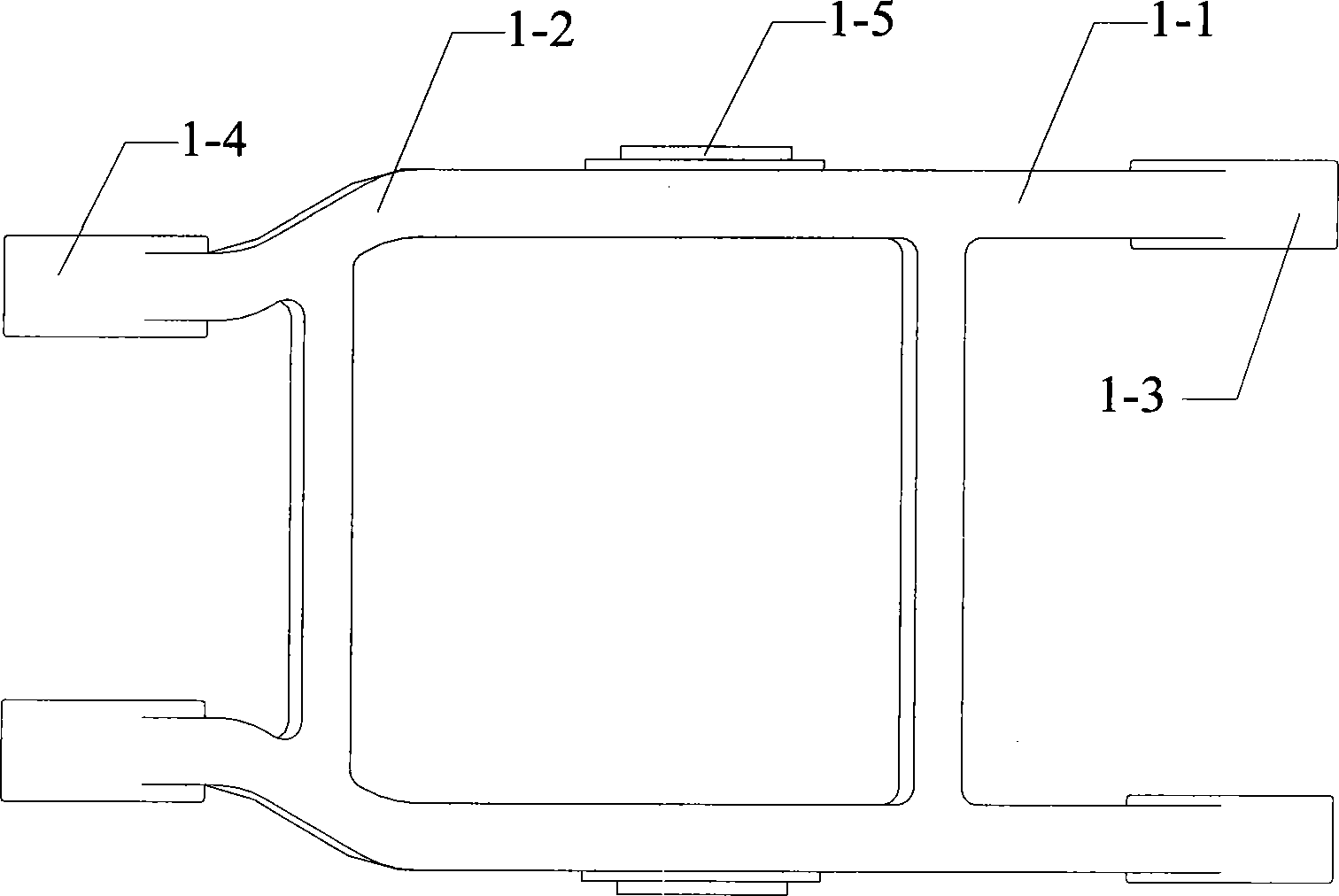

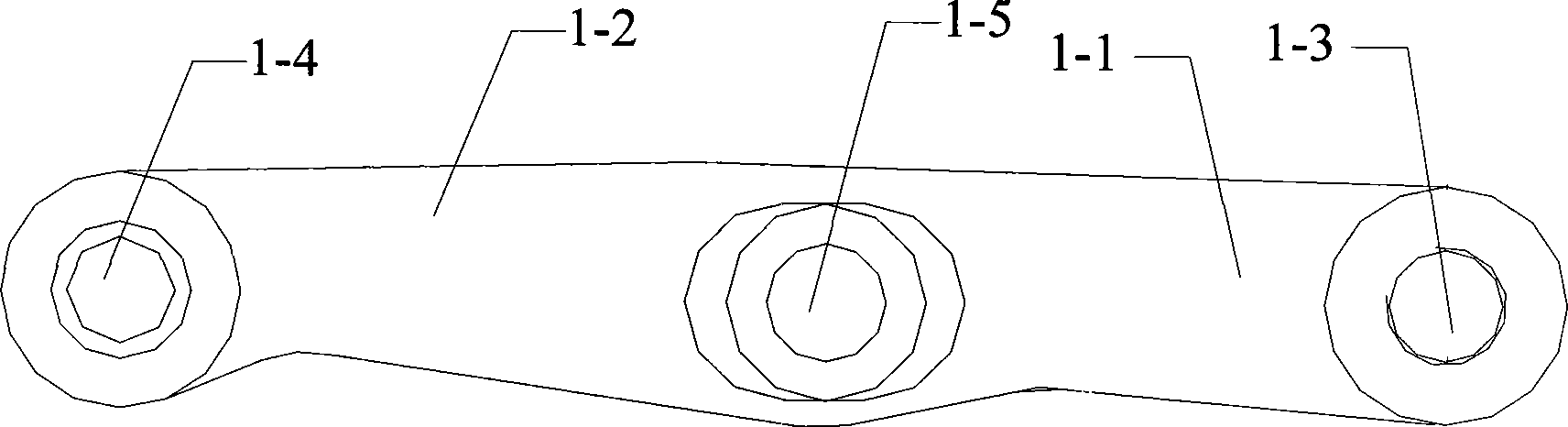

[0039] refer to Picture 1-1 and Figure 1-2 , showing respectively the structural front view and the bottom view of an embodiment of the lever used by the disc-shaped train braking device of the present invention, including a power arm 1-1 and a resistance arm 1-2, and the power arm 1-1 and resistance of the lever The length of arm 1-2 is determined by the design speed V of the train 0 , effective braking distance S e , mass m, axle load M, wheel diameter D, number of brake discs n and friction radius r, effective diameter of unit brake cylinder d z and the total length of the lever L and other parameters, the calculation process is as follows:

[0040]1. Determine the emergency braking distance S of the train z

[0041] Acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com