Axle connecting plate and air pressure disc brake of support invisible composite structure of axle connecting plate

A disc brake and connecting plate technology, applied in the field of vehicle parts, can solve the problems of reducing product thickness, safety hazards, and structural strength reduction, and achieve the effects of reducing processing difficulty, cooperating with installation assurance, and braking safety and effectiveness

Inactive Publication Date: 2022-05-31

山东清越科技有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] However, in order to ensure the structural strength and braking effect of the current pneumatic disc brake structure, the structure is usually thicker, the volume is larger, and the manufacturing cost is relatively high.

[0004] Directly reducing the thickness of the product will lead to a decrease in structural strength, which poses a safety hazard

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0039] The novel connecting plate structure of the present invention avoids the problems that the previous welding strength is not enough, and the problem of force deformation and replacement is difficult.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

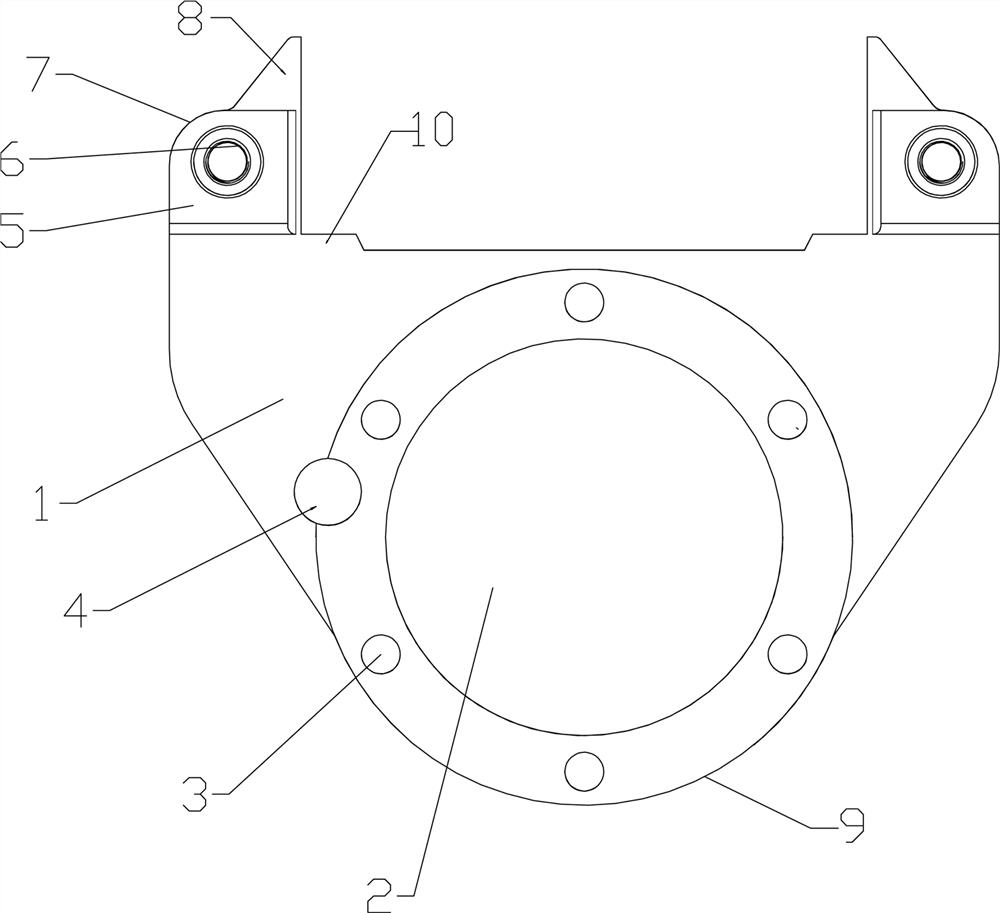

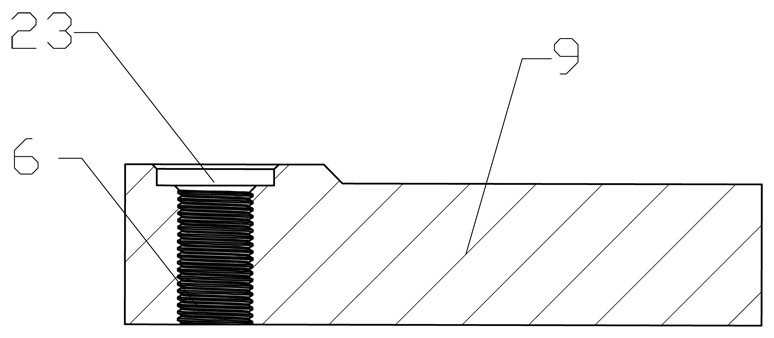

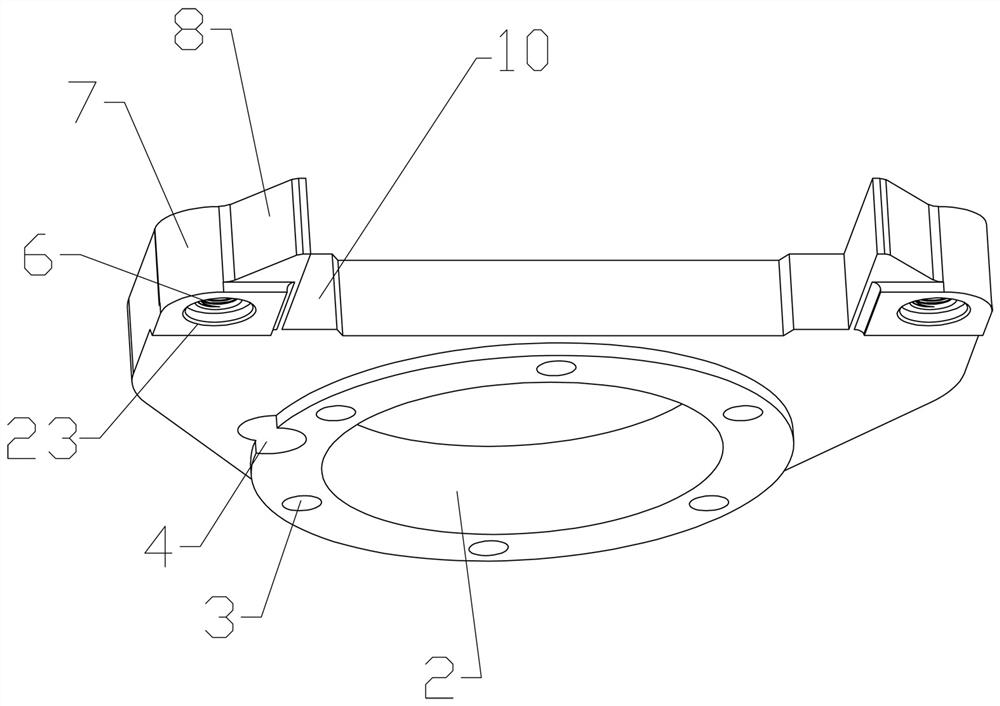

The invention relates to a brake block axle connecting plate and an air pressure disc brake thereof, and belongs to the field of vehicle parts. According to the technical scheme, the brake block axle connecting plate comprises a connecting part located on the lower portion, the connecting part is of a plate-shaped structure, a shaft hole is formed in the lower portion of the connecting part, a plurality of axle connecting holes and an ABS alarm line mounting hole are formed in the periphery of the shaft hole, and the hole diameter of the shaft hole is smaller than that of a middle hole of a brake disc. The ABS alarm line mounting hole is positioned in a mapping range from a middle hole of the brake disc to the side surface; the limiting parts are located on the two sides of the upper portion of the connecting part and are symmetrically arranged on the two sides, the brake block is installed between the limiting parts on the two sides, the limiting parts are provided with guide pin connecting holes, external corners are filleted corners, and triangular wedge-shaped structures are arranged on the upper portions of the limiting parts. The brake caliper is in a brand new state, the brake caliper body is matched with the positions of the invisible support and the connecting plate, matched installation of the brake block is achieved, safe and effective braking is guaranteed, and the traditional mode that the brake block is fixed through the support is changed.

Description

Pneumatic disc brake with invisible composite structure of axle connecting plate and its bracket technical field [0001] This patent relates to a brake block axle connecting plate and its pneumatic disc brake, belonging to the field of vehicle parts. Background technique Most of existing vehicle assembly is still traditional drum brake, but with the implementation of the new GB7258 national standard, Disc brakes have gradually switched to the heavy commercial vehicle market due to their high braking energy efficiency and good heat dissipation. But the current pneumatic disc brake structure in order to ensure the structural strength and braking effect, usually the structure is relatively Thick, bulky, and relatively expensive to manufacture. [0004] Directly reducing the thickness of the product will lead to a reduction in structural strength, and there is a potential safety hazard. To achieve lightweight products In order to reduce the material cost, it is necessary...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16D65/095F16D55/22F16D65/00B60T1/06B60B35/00

CPCF16D65/095F16D55/22F16D65/0068B60T1/06B60B35/00Y02T10/86

Inventor 张越张中国石彬杨传亮胡大猛王伟达李雪伍许崇海肖光春吕煜坤刘金刚

Owner 山东清越科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com