Paper packaging material and paper container made of same

A technology for paper containers and paper packaging materials, applied in the field of paper containers, can solve the problems of poor food taste, scalding, and falling to the same room temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

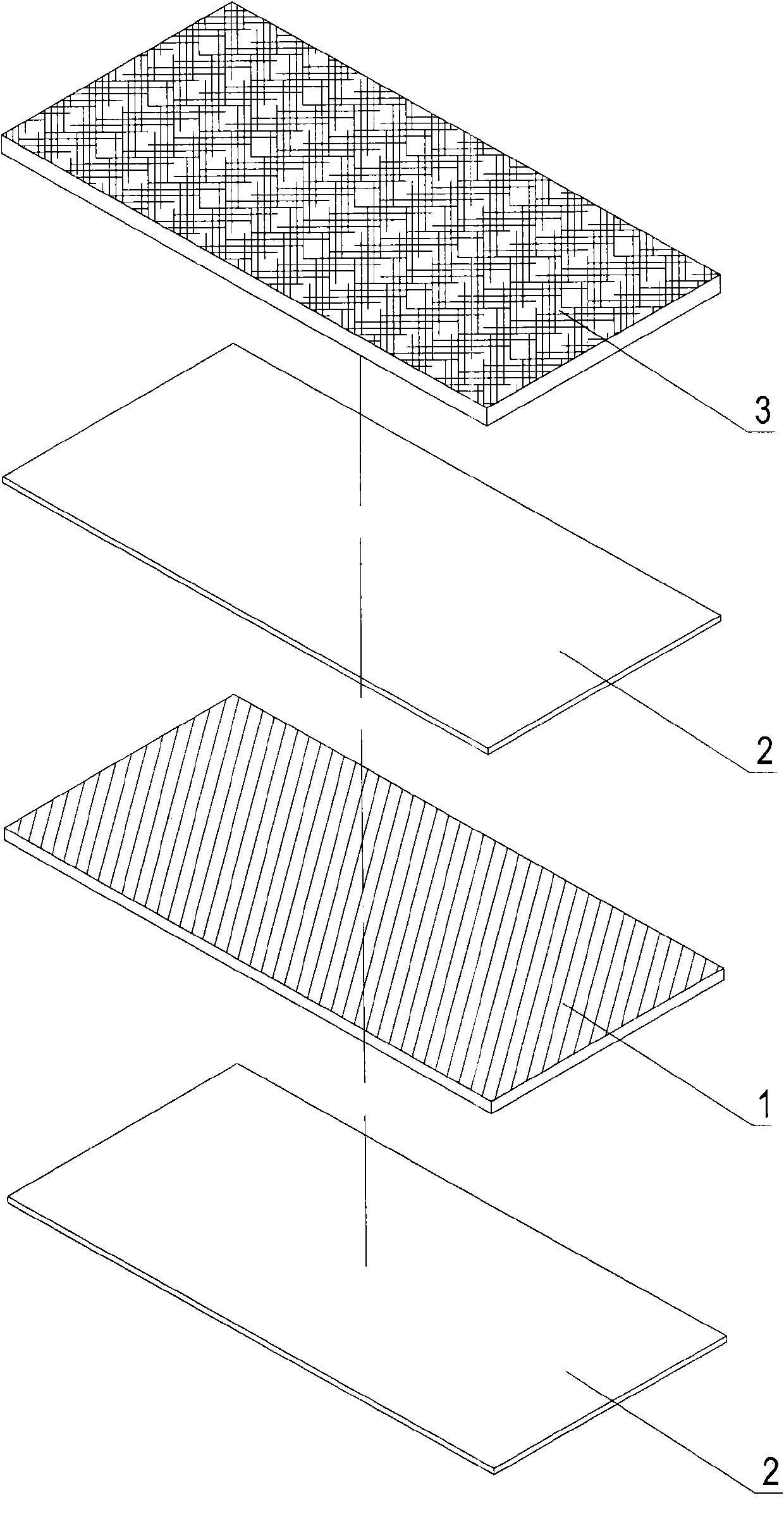

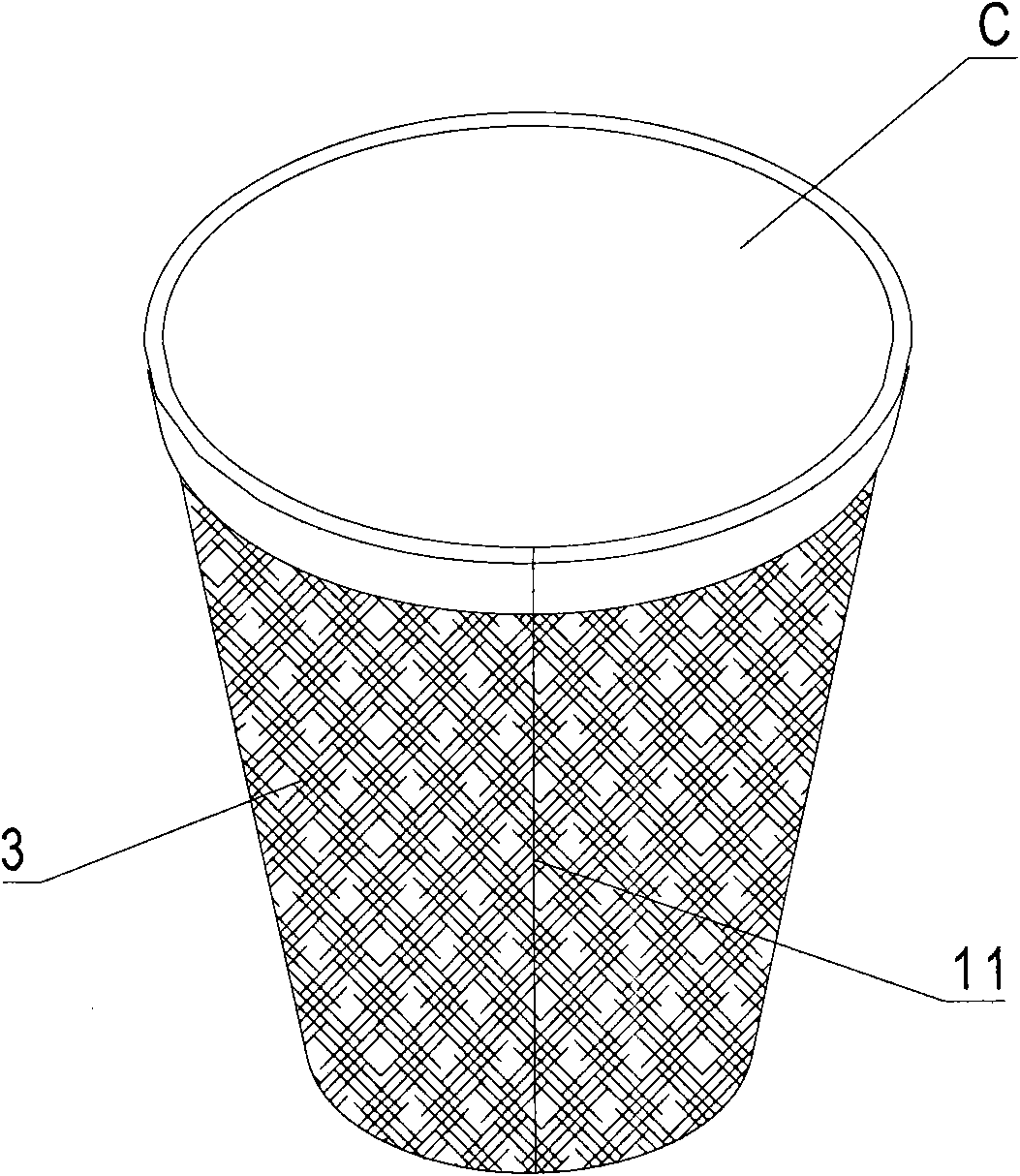

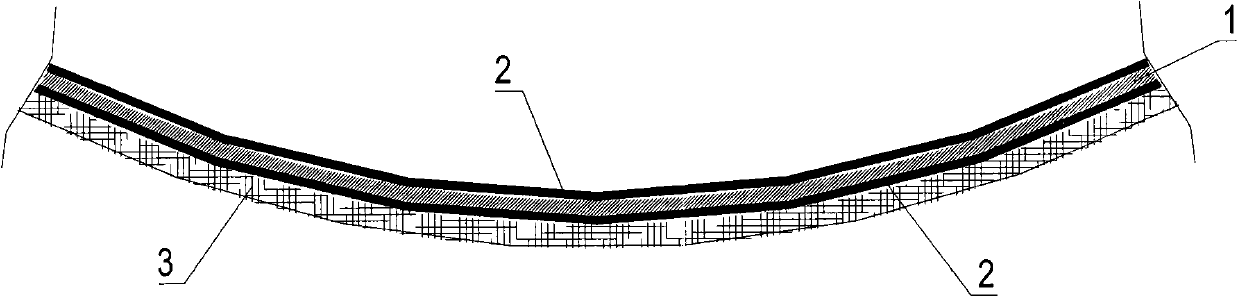

[0024] see figure 1 As shown, a film layer 2 is coated on both sides of a paper 1. The film layer 2 can be made of biodegradable or environmentally friendly materials for waterproof leakage and bonding. A composite fiber cloth 3 is attached to the outer plane of layer 2. The composite fiber cloth 3 is made of biodegradable or environmentally friendly woven or non-woven fabrics to increase the overall strength, and then heat the coating layer at high temperature 2. Various paper containers C are formed by pasting the connecting end 11. The paper container C can be a cup body or a box body, etc., and the coating layer 2 is separated between the paper 1 and the composite fiber cloth 3. It has the function of absorption, while covering the outer edge has the function of insulation; with this structure, it can achieve the functions of heat insulation, ice preservation, heat preservation, oil absorption, water absorption and fresh preservation, so as to reduce costs and increase ben...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com