Preparation method of expansive concrete containing steel slag

A technology of expansive concrete and steel slag concrete, applied in the field of building materials, can solve the problems of limited wide application, large actual dosage, unsuccessful and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

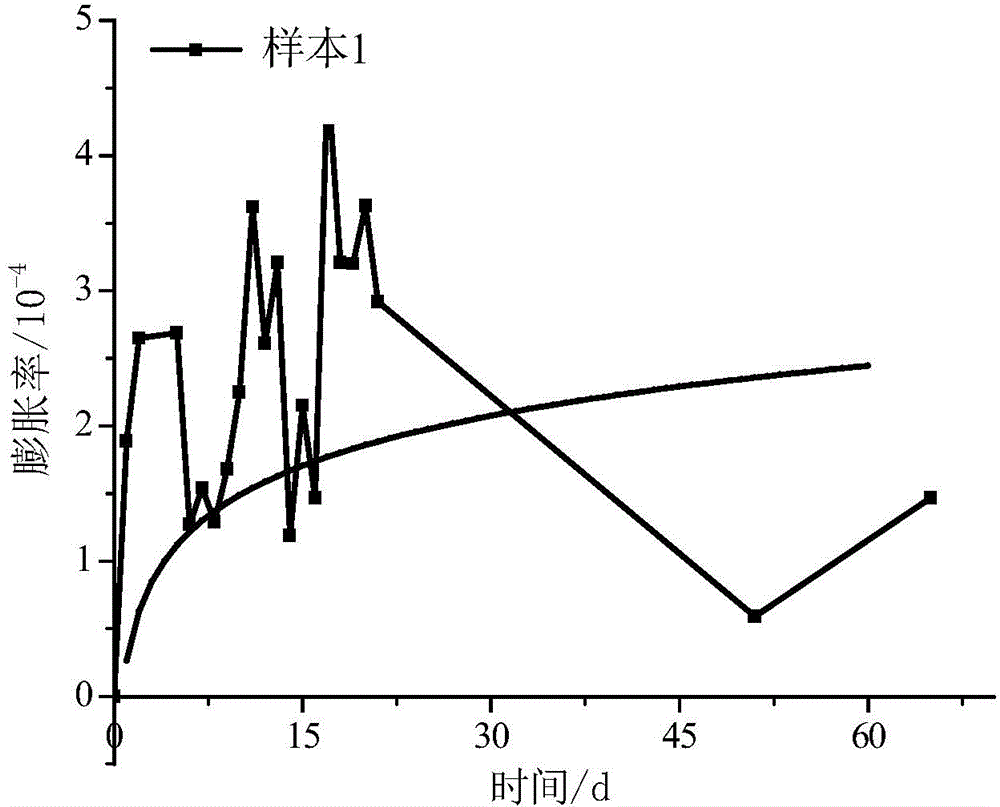

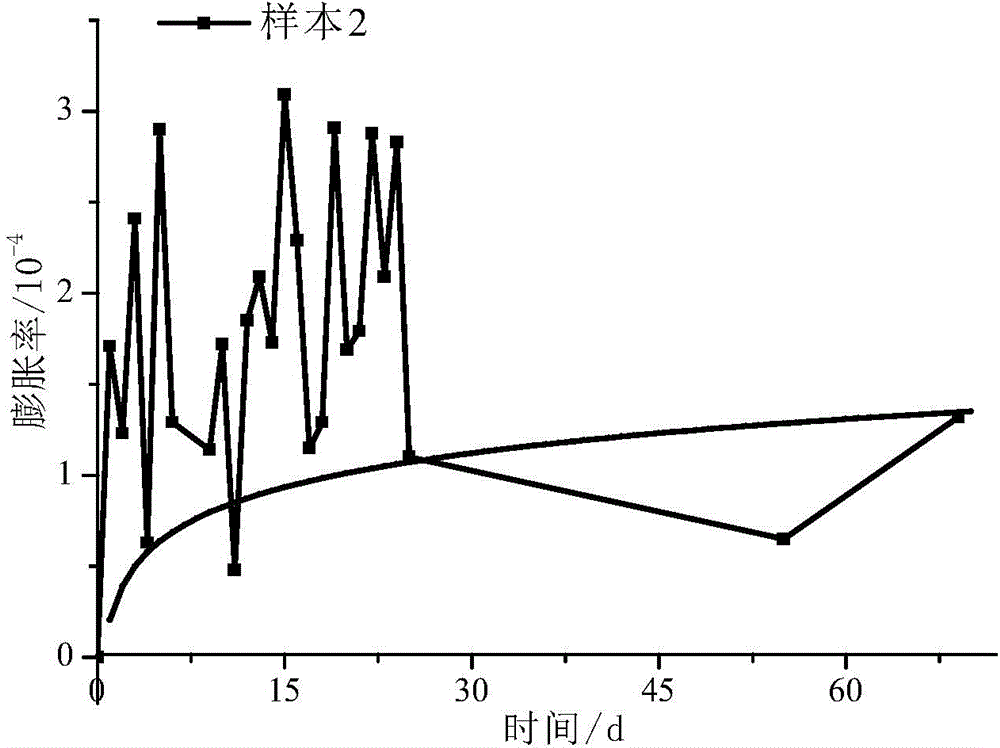

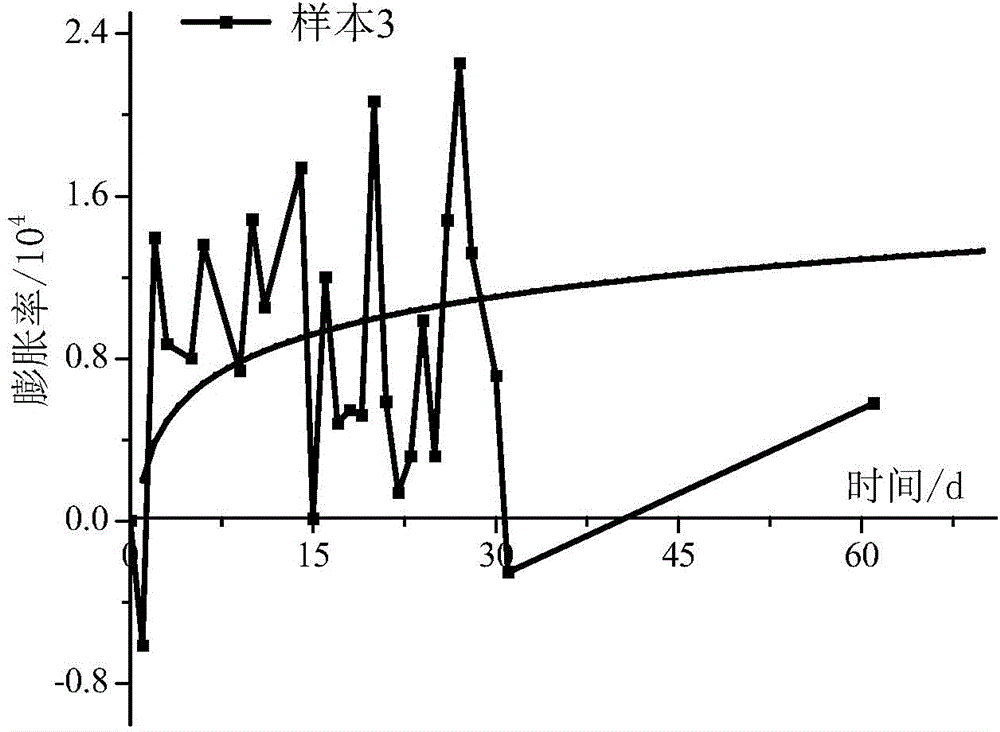

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with specific examples of steel slag expanded concrete.

[0037] Steel slag is a kind of industrial waste, and the present invention selects steel slag to be steel slag of Masteel, adopts X-ray fluorescence spectrum analysis (XRF) to record the chemical composition of steel slag as shown in table 1, as can be seen from table 1, the chemical composition of steel slag and Similar to cement, it has certain hydraulic activity, and steel slag contains active components such as CaO, which is the main factor for the expansion of steel slag concrete. The particle diameter range of the steel slag sand in the present invention is 0.15~4.75mm, and the apparent density is 3590kg / m 3 , the moisture content is 2.6-4.39%, the fineness modulus is controlled between 2.7-3.0, and it belongs to the middle sand zone II. Single-graded coarse aggregate with a coarse steel slag particle size of 4.75-9.5mm and an apparent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com