Spiral oil pumping device

A helical, oil-pumping technology, which is applied in the fields of fluid production, wellbore/well components, and earth-moving drilling, etc., can solve the problems of high cost, many consumables, large volume and weight, etc., and achieves low manufacturing and use costs and increases The effect of oil delivery pressure and overall small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below with reference to specific embodiments and accompanying drawings.

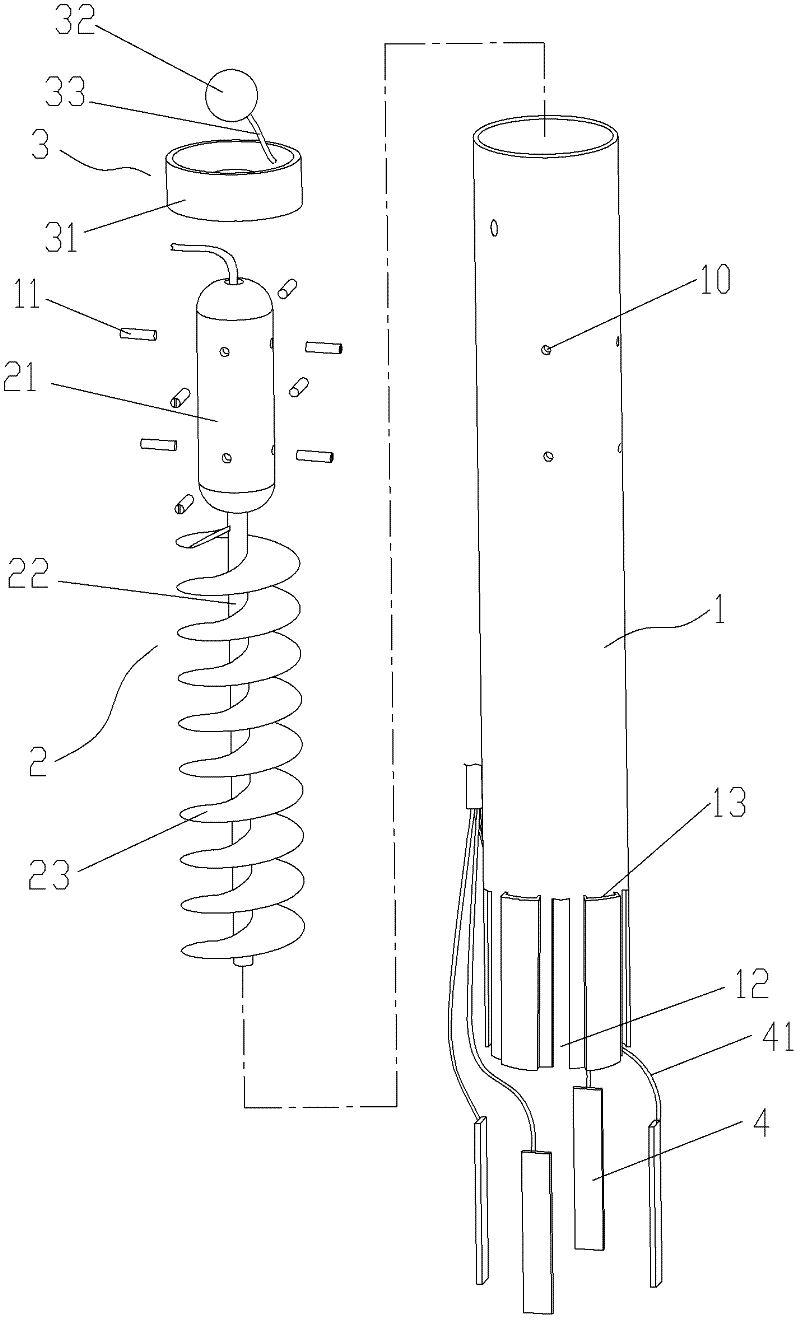

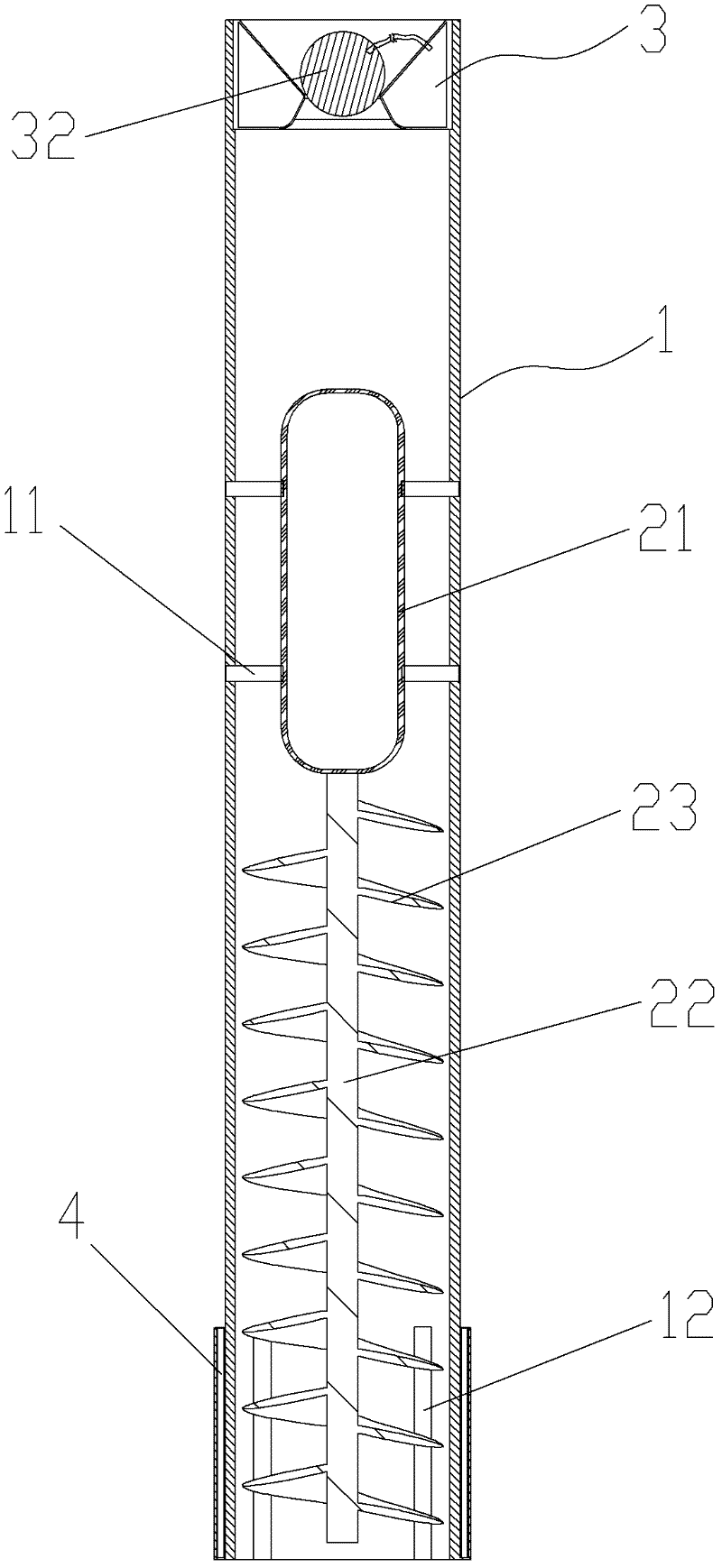

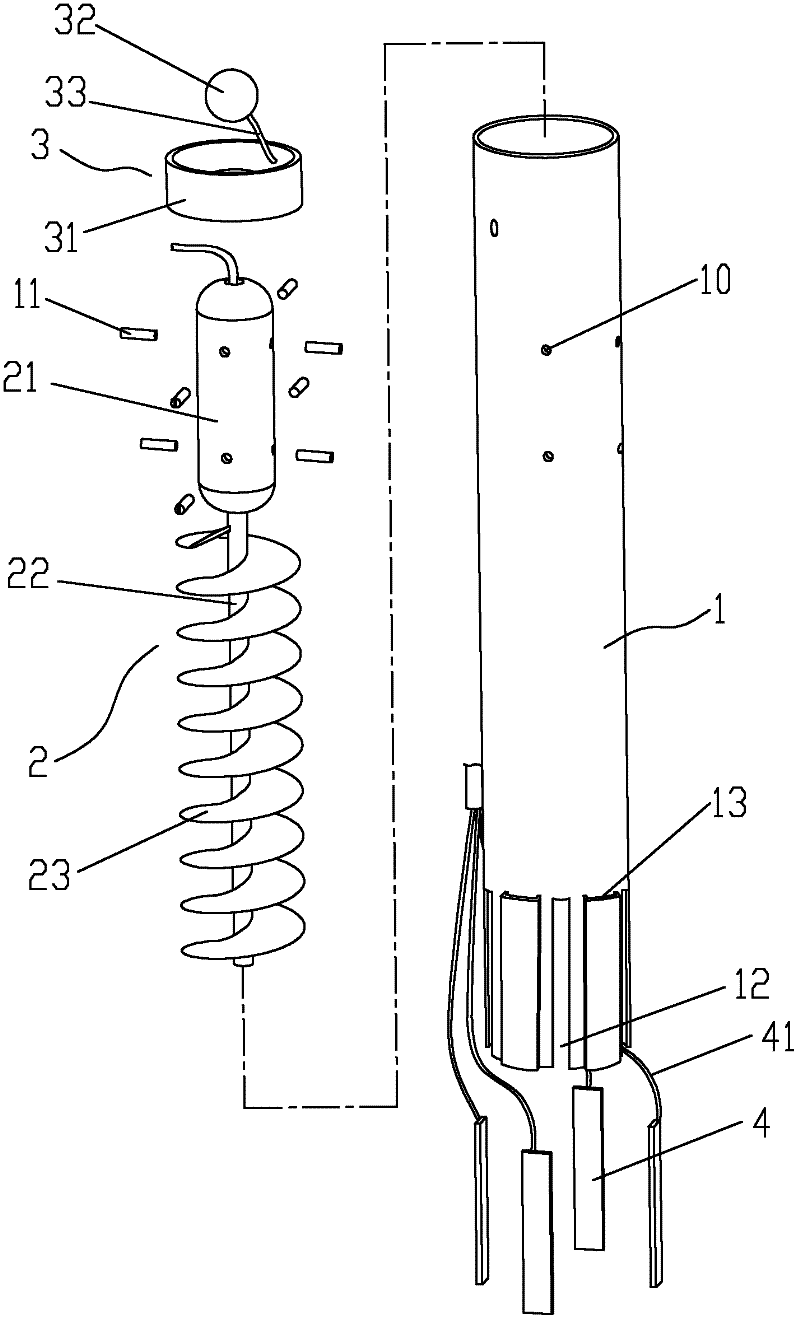

[0013] like figure 1 , 2 As shown in the figure, the screw type oil pumping device of the present invention includes an oil pumping drum 1 with two ends open, and an oil extraction unit 2 is installed in the oil extraction drum 1 along the axial direction. The drive motor 21 and its output shaft 22 installed at intervals and coaxial with the oil sucking drum 1, and the helical fins 23 arranged on the output shaft 22; and the output shaft 22 and the helical fins 23 extend to the oil sucking A check valve 3 is also installed at the oil outlet port of the oil pumping drum 1 .

[0014] Specifically, the oil sucking drum 1 is provided with several radial screw holes 10 , and each radial screw hole 10 is provided with a fixing bolt 11 for positioning the driving motor 21 , that is, the fixing bolt 11 extends from the radial screw hole 10 . 10 penetrates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com